LT-1859

2

GENERAL INFORMATION / THEORY OF OPERATION

TABLE OF CONTENTS

I. GENERAL INFORMATION

A. Initial Inspection ................................................................... 2

B. Maintaining the PD1000............................................................. 2

C. General Description ................................................................ 2

II. THEORY OF OPERATION ............................................................. 2

III. INSTALLATION AND OPERATION

A. Installation ....................................................................... 3

B. Operation ........................................................................ 3

IV. MAINTENANCE PROCEDURES

A. Testing .......................................................................... 4

B. Cleaning......................................................................... 4

V. TROUBLESHOOTING................................................................. 5

VI. SERVICE INSTRUCTIONS

A. Regulator Seal Replacement......................................................... 6

B. Battery Replacement ............................................................... 6

C. Cover / Regulator and Gauge Removal ................................................ 6

D. Cannula Fitting Removal/Replacement ................................................. 7

E. Solenoid/Vacuum Switch Testing and Removal........................................... 7

VII. PARTS AND IllUSTRATIONS ........................................................... 8

VIII. PNEUMATIC DIAGRAM ............................................................... 9

IX. UNIT SPECIFICATIONS ............................................................... 9

X. PROVIDER'S NOTES ................................................................. 9

XI. DEVILBISS GUIDANCE AND MANUFACTURER’S DECLARATION ............................ 10

XII. PARTS RETURN AND ORDERING POLICY ............................................... 11

XIII. WARRANTY ........................................................................ 11

I. GENERAL INFORMATION

A. Initial Inspection

An initial inspection should be performed on the PD1000 as soon as possible after receipt. When removed from

carton, an inspection should be made for any damage due to shipping. If shipping damage has occurred, call

DeVilbiss Healthcare at 800-338-1988 (814-443-4881) for replacement instructions.

B. Maintaining the PD1000

The PD1000 should be periodically maintained according to the guidelines set forth in Section IV. Maintenance, and

testing should only be done by qualied service personnel. Failure to follow the procedures set forth in this manual

may void the warranty.

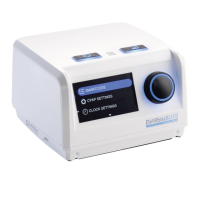

C. General Description

The PD1000 PulseDose system delivers a pulse or "bolus" of oxygen at the leading edge of inspiration. This bolus is

delivered at both the proper ow and volume so that it is delivered deep into the lungs where gas exchange takes

place. The PD1000 PulseDose is rate responsive from 6 BPM to 40 BPM.

II. THEORY OF OPERATION

The PD1000 utilizes a vacuum switch to detect the negative pressure at the beginning of each inspiration

(approximately .1 inches water column due to inhalation). That, in turn, opens the solenoid for a time interval that

corresponds to the ow rate selected on the rotary selector. At higher ow rates, the valve is open longer resulting in

increased pulse volumes.

Atmospheric pressure compensation occurs automatically because the pressure side of the vacuum switch is open

to atmosphere.

All PD1000 units are set on 2 liters per minute continuous ow from the factory. Changing to a different continuous

ow rate involves changing the cannula tting as outlined in Section VI, D.

The PD1000 delivers 16.5 cc 0

2

per setting number (i.e. setting 2 = 33cc 0

2

).

Loading...

Loading...