Water Valves

Remove top panel to access water valves. (see Removing Top Panel) The two dual outlet water valves are

mounted to the rear channel with two screws each. Always check inlet screens to be sure that they are

clean. Disassembly requires the removal of two solenoid screws and three valve body screws. Below the

solenoid coil is a solenoid guide, armature, armature spring and diaphragm. All valve parts are available

individually or as a complete unit.

Door Lock Assembly Operation

After loading the clothing, the door should be closed and latched. The locking cam on the door contacts

the latching switch actuator which closes the latching switch. The specied number of coins should now

be added to start the washer. The solenoid pulls up on the locking pawl by use of a linkage rod. The

locking pawl has two jobs. The rst is to lock the door. This is accomplished by blocking the locking cam

on the door so that it can’t rotate to unlock. The second job is to close the two piggyback lock sensing

switches. These switches control power to all of the controls. If the door unlocks for any reason, these two

switches will stop the machine. When the door handle is 1/4 to 1/2 of an inch from its fully closed position,

the latching switch should close. The two piggyback lock sensing switches should be open when the door

is unlocked and should be closed when the door is locked.

Accessing the Door Lock Assembly

After removing the front panel and masking ring, the door lock assembly can now be accessed.

Adjustment for Door Lock Assembly

The latching switch and the piggyback lock sensing switches all have slotted mounting for easy

adjustment.

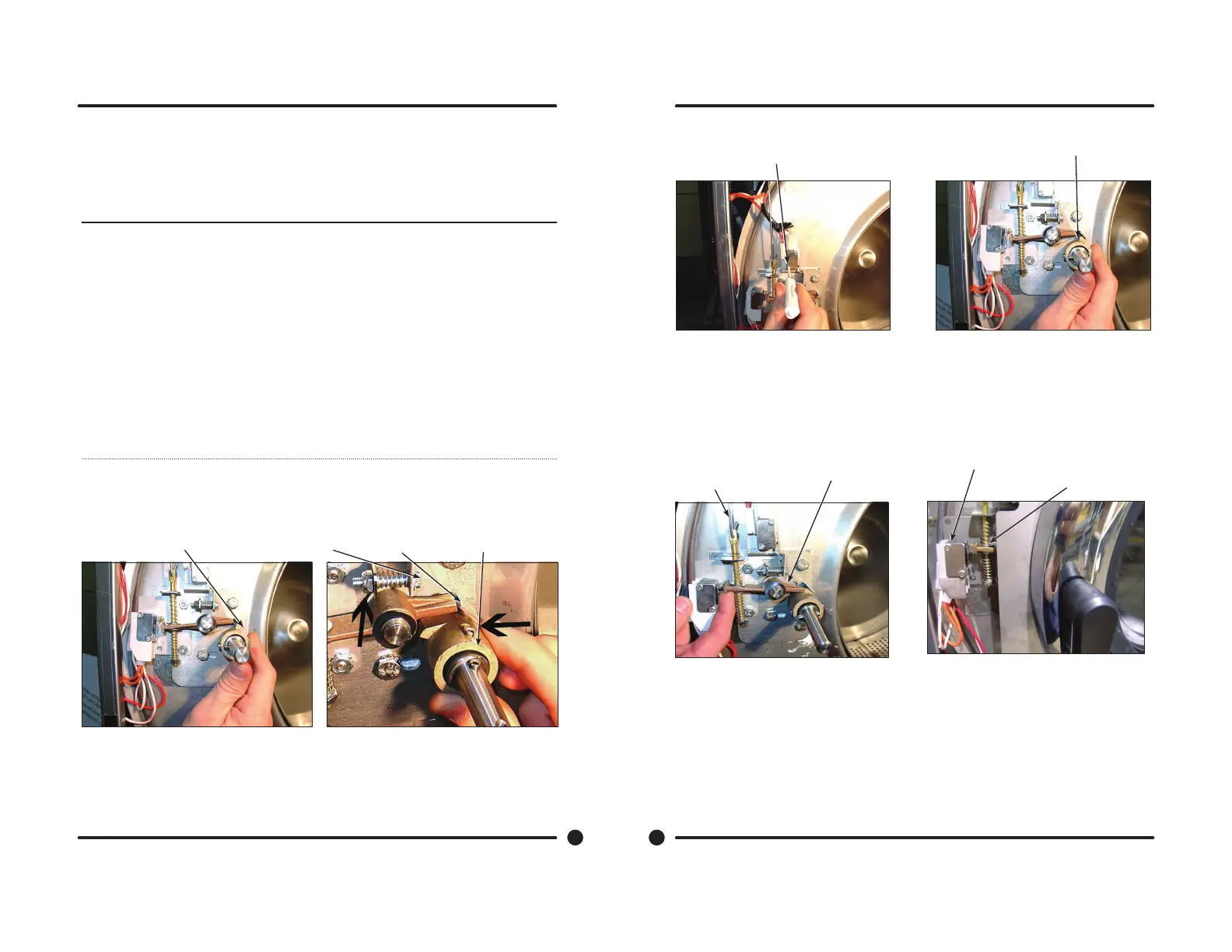

Step 1: Set door cam over pin. Here you can see

the Door CAM away from the door lock

assembly.

Step 2: Tighten spring screw on switch actuator

bracket arm until it just clears cam OD. at

base of door lock assembly.

Adjustment to this bracket usually is not

necessary as next step is used more in

eld.

49

Part # 8533-053-001 REV 4/09

Spring screwJust clear here

Switch actuator

bracket

Door cam sample

Step 4: Check for switch actuation at partial

turn of cam as in operation above. Door

handle goes from horizontal to six o’clock

vertical.

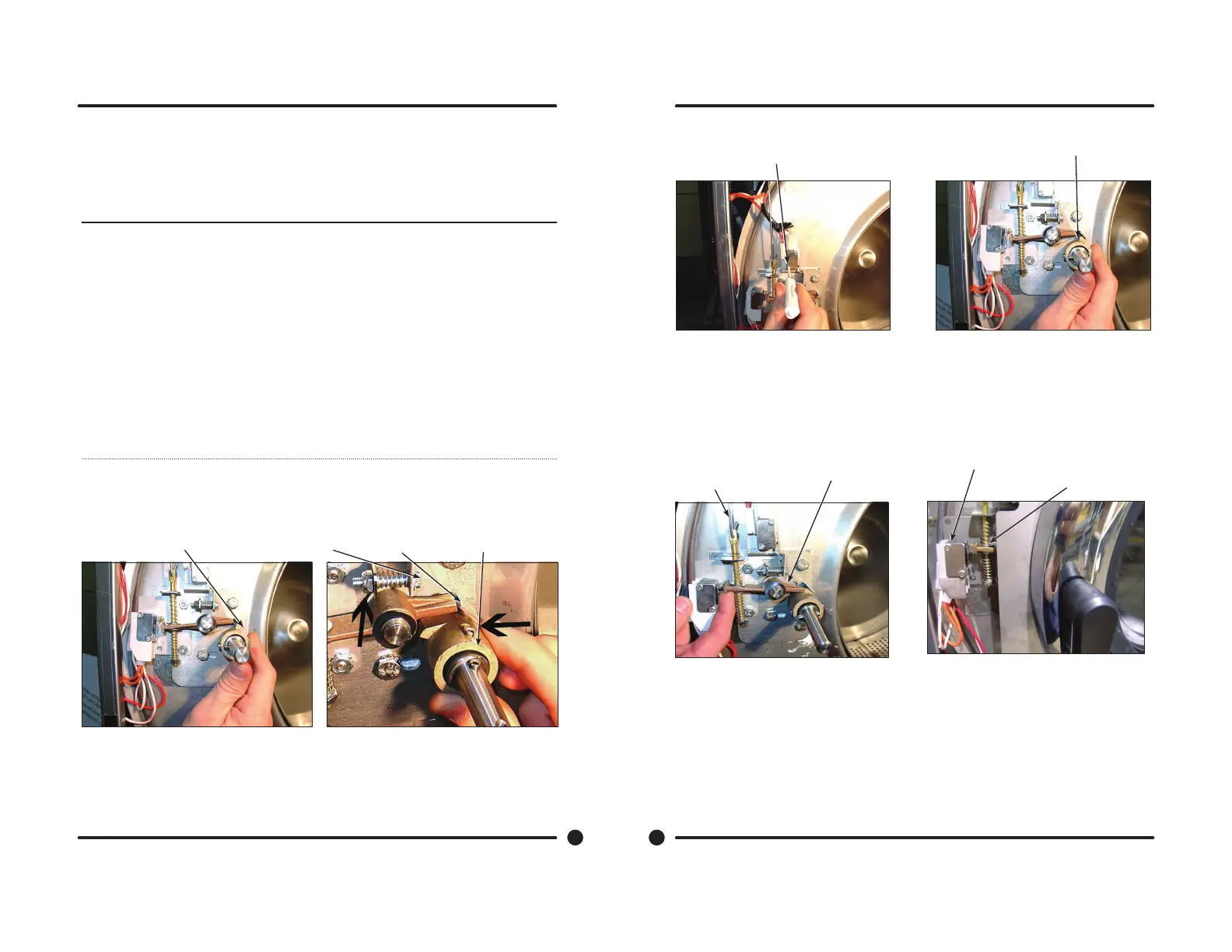

Step 3:

With switch actuator bracket adjusted you

will now need to adjust single switch by

loosening 2 at brade screws and allowing

swivel of switch. Move switch towards above

bracket until it actuates. Now tighten at

blade screws. Use a .040 thickness guage

to insert between bracket and switch and

the switch should close and open again

upon removal of thickness guage.

Step 5: Check that lock pawl arm swings to cam

lobe to lock position.

Step 6: The lock stacked switches (piggyback)

must be adjusted as door lock solonoid

pulls up on door rod and locking pawl is

now blocking door cam from turning and

is in full up position. The stacked swtiches

(piggyback) have a single actuator arm

and it must actuate when single actuator

roller wheel rolls to at side of locking

pawl. You will also notice a .040 gap

between actuator arm and switch bodies.

Note: Both stacked switches must operate

together!

50

Part # 8533-053-001 REV 4/09

Flat blade screw on

door switch latching

Door lock rod

Locking pawl blocking

Adjustment screw for

(piggyback switches)

Top of at end

of locking pawl.

Door cam

check position

Loading...

Loading...