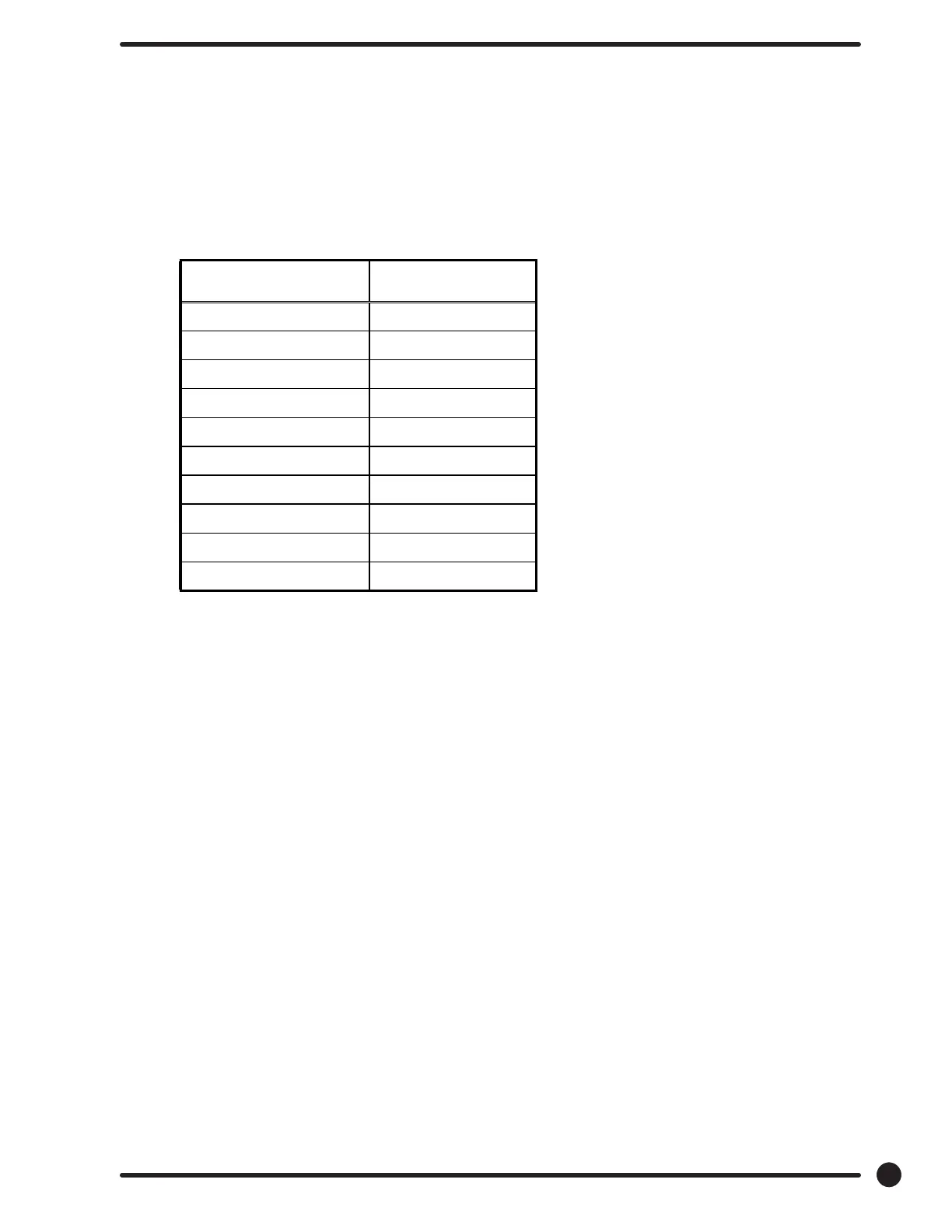

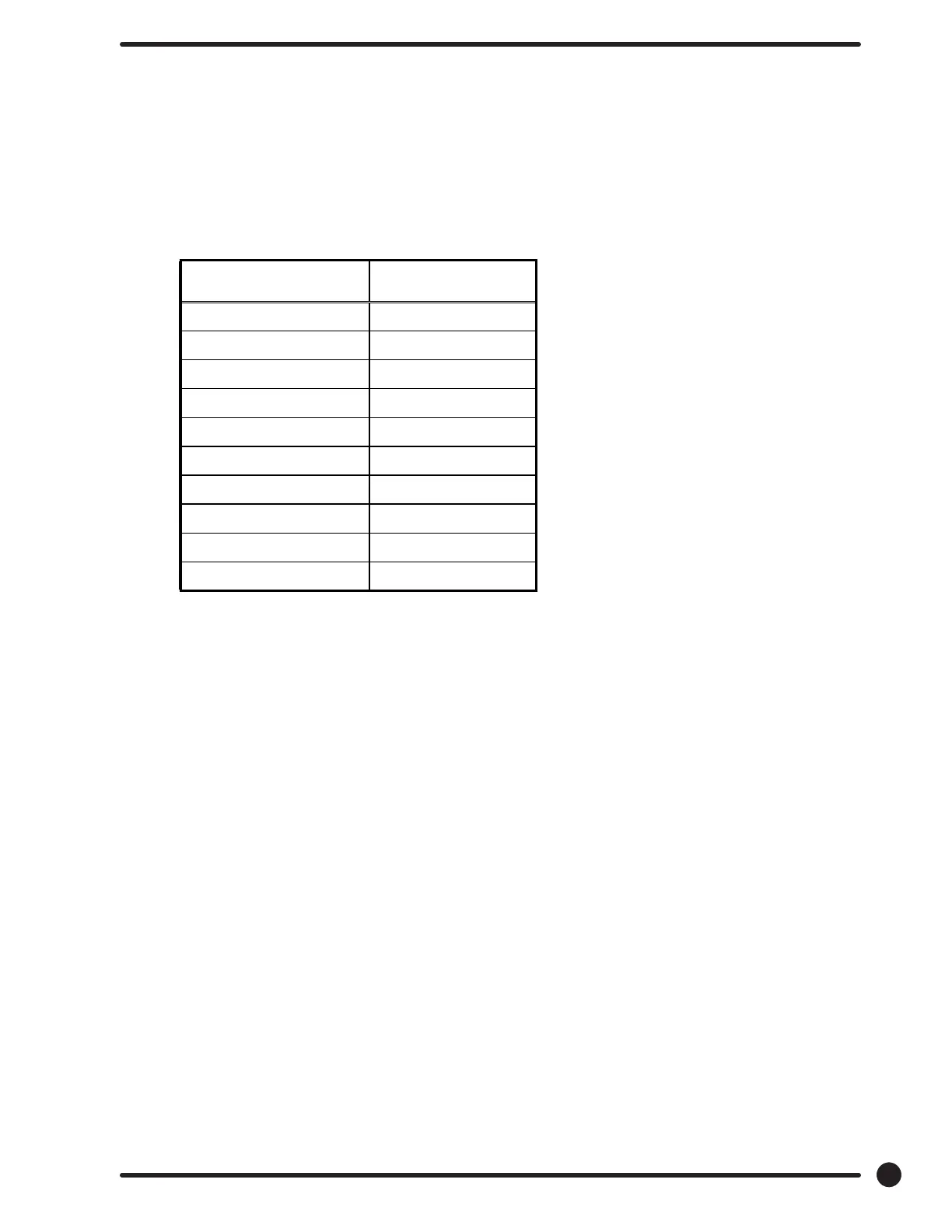

INJECTION SOURCE CONNECTIONS

The washer control may be programmed to send ten 120VAC output signals for 60Hz models (or 24VAC

for 50Hz) for a chemical injection system. The signals are not intended as a power source and must be

limited to less than 100 milliamps of current. There is a separate terminal block for connection of the

external injection signals. For the injection sources, program codes 1 through 10 and their respective

terminal block connections are as shown in Table 1.

Table 1: Injection Signal and Circuit Identication

If required, chemical injection hoses are to be inserted into the injection inlet at the upper right rear of the

washer. These hoses should be inserted into the round PVC pipe a distance of:

T-650, 750, 950 and 1450 a minimum of 14” (36 cm) and a maximum of 18” (46 cm)

This will eliminate chemical buildup in the pipe and/or restrict water ow to the tub. Secure the hoses as

required.

Fusing Requirements:

Dual element time delay fuse or equivalent breaker of amperage specied below.

•1 Phase or 3 Phase 15 amp, 208-240VAC

•WN0650-12, WN0750-12, WN0950-12, and WN1450-12

•1 Phase 15 amp, 230VAC

•WN0650-39, WN0750-39, WN0950-39, and WN1450-39

OPERATION CHECK

During intermediate spin and nal spin, the cylinder should turn in a counterclockwise direction when

viewed from the front of the machine. If spin is clockwise, the T1 and T2 motor wires connecting to

terminal T1 and T2 on the variable frequency drive should be swapped. Remove power to the machine

before opening service panels and swapping wires.

Dexter Recommended

Connections

Controller / Injector

Signals

Detergent 1

Bleach 2

Starch 3

Sour/Softener 4

5

6

7

8

9

10

27

Part # 8533-110-001 11/20

Loading...

Loading...