3 Troubleshooting

ECO 9099 SOP05-5090F Rev.00 Effective Date: 12/20/18 Page 56 of 58

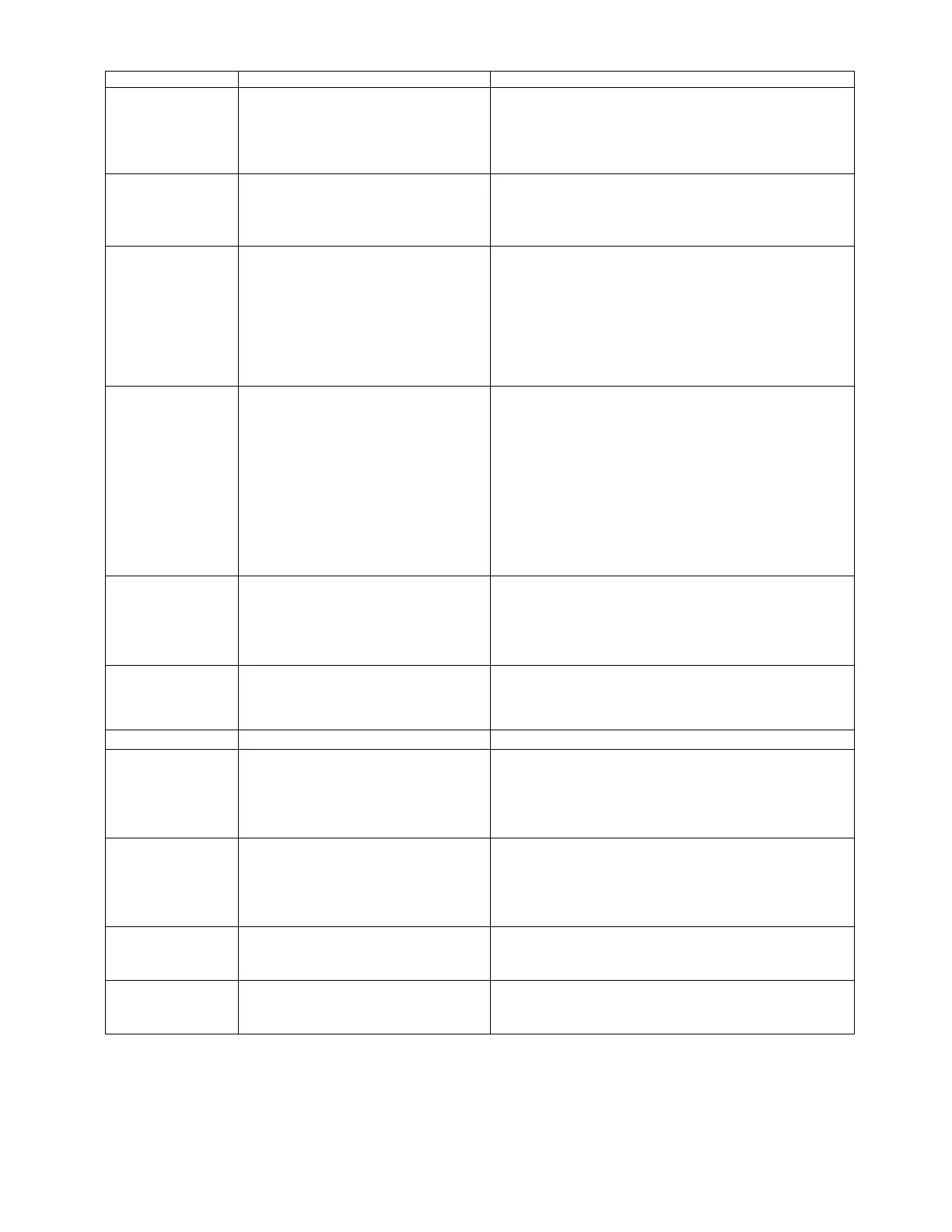

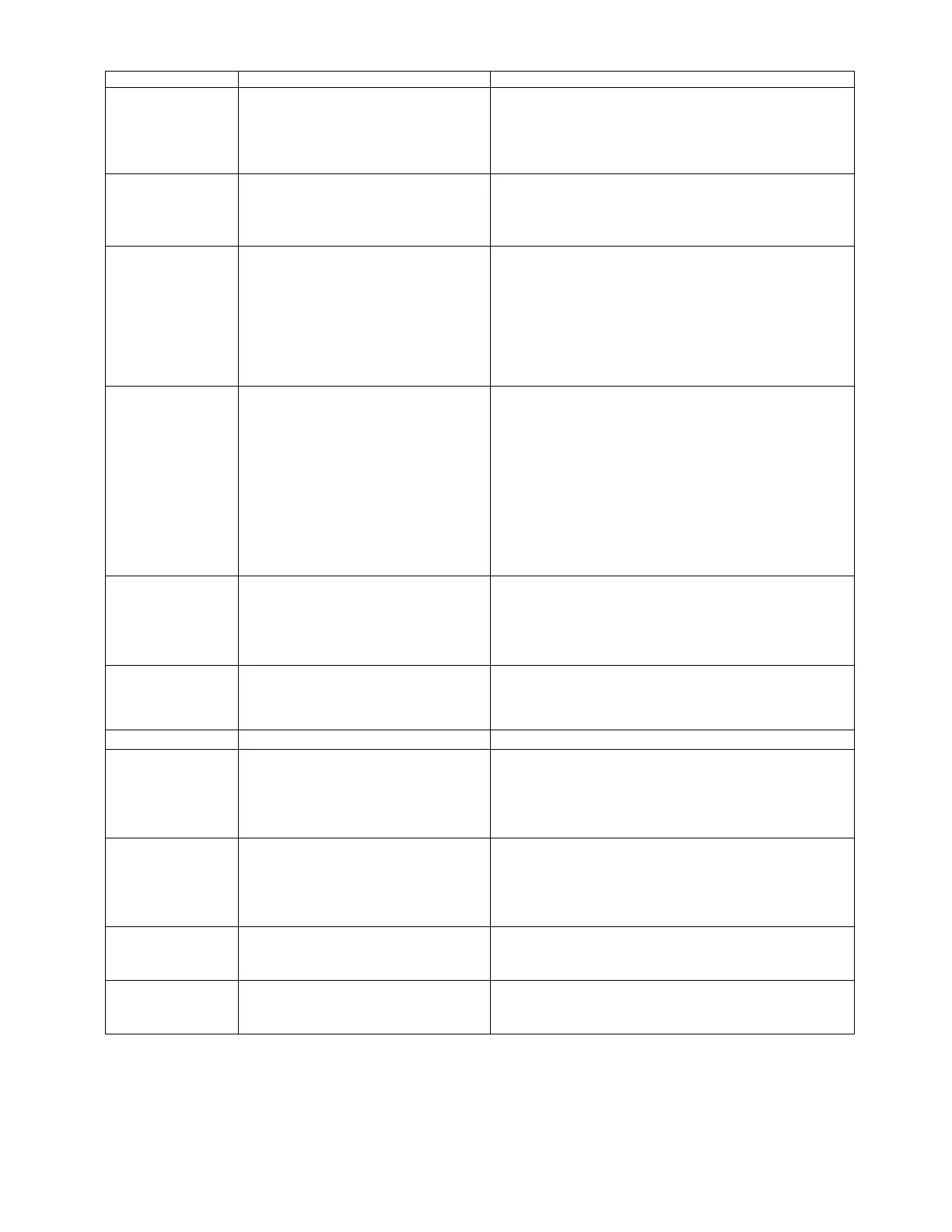

Instrument is performing an active

task and cannot start another task in

parallel.

•

Wait for a few minutes for active task to finish

and try again

•

If still not cleared, reboot the analyzer,

MAIN

OPERATIONS MENU>>>INSTRUMENT

SETTINGS>>>SYSTEM>>>REBOOT

The solenoids overheated or are

improperly connected. The solenoid

valve have thermal fuses that reset.

•

Turn power off for 1 hour to cool.

•

Check room temperature within specified limits of

15

o

C to 32

o

C

•

Ensure all pinch valves properly connected.

If the analyzer displays multiple

arrows up or down instead of the

sample results, the concentration of

the sample is outside of the

measurement range

•

For urine sample, arrows up instead of the K+-

result indicate that further dilution is necessary

(see chapter 3.3.4: “Urine samples”).

•

Check for Proper sample preparation (see

chapter 3).

•

Check for small air bubbles in the sample after

aspiration into the sample chamber.

•

Check for proper aspiration of standard A.

Indicates if measured value is above

or below expected values for

temperature, cal values, or sample

values

• Temperature sensor is in the sample sensor. Verify

sample sensor plugged in securely

• Check room temperature within specified limits of

15

o

C to 32

o

C.

• Check temperature test MAIN OPERATIONS

MENU>>>DIAGNOSTICS>>>CHECK

TEMPERATURE

• If temperature is not within 1 to 2 degrees of room

temperature, replace sample sensor.

• If new sample sensor does not fix the error, replace

Error

Bad connection between display,

CPU and interface PC

•

Check the flex ribbon connectors between

Display, CPU and interface PC.

•

Restart the unit and ensure pump turns on at

power cycle.

•

Contact support if problem persists

Old electrode that are drifting.

Sample STD-A readings where not

close to STD-A reading during

•

Check the STD-A mV for sample and calibration

•

Re-calibrate the instrument

•

Change the electrode

Flash memory storage malfunctioned

•

Contact support to get CPU replacement

Or Invalid Data

Data loss during communication

between interface PC and CPU

board.

•

Check the flex ribbon connectors between

Display, CPU and interface PC.

•

Restart the unit and ensure pump turns on at

power cycle.

•

Contact support if problem persists

Or No Error

display/print/analyze

•

Check if data is saved properly after each

sample analysis

•

Check input range and date range

•

Try to search data remotely using remote

Fluid pack is missing or not installed

properly

•

Ensure pack is installed and inserted all the way

in connecting to manifold

•

Check fluid pack sensor under diagnostic menu

Instrument was not calibrated before

running sample

•

Calibrate the instrument

•

Ensure current electrode configuration is marked

Loading...

Loading...