27

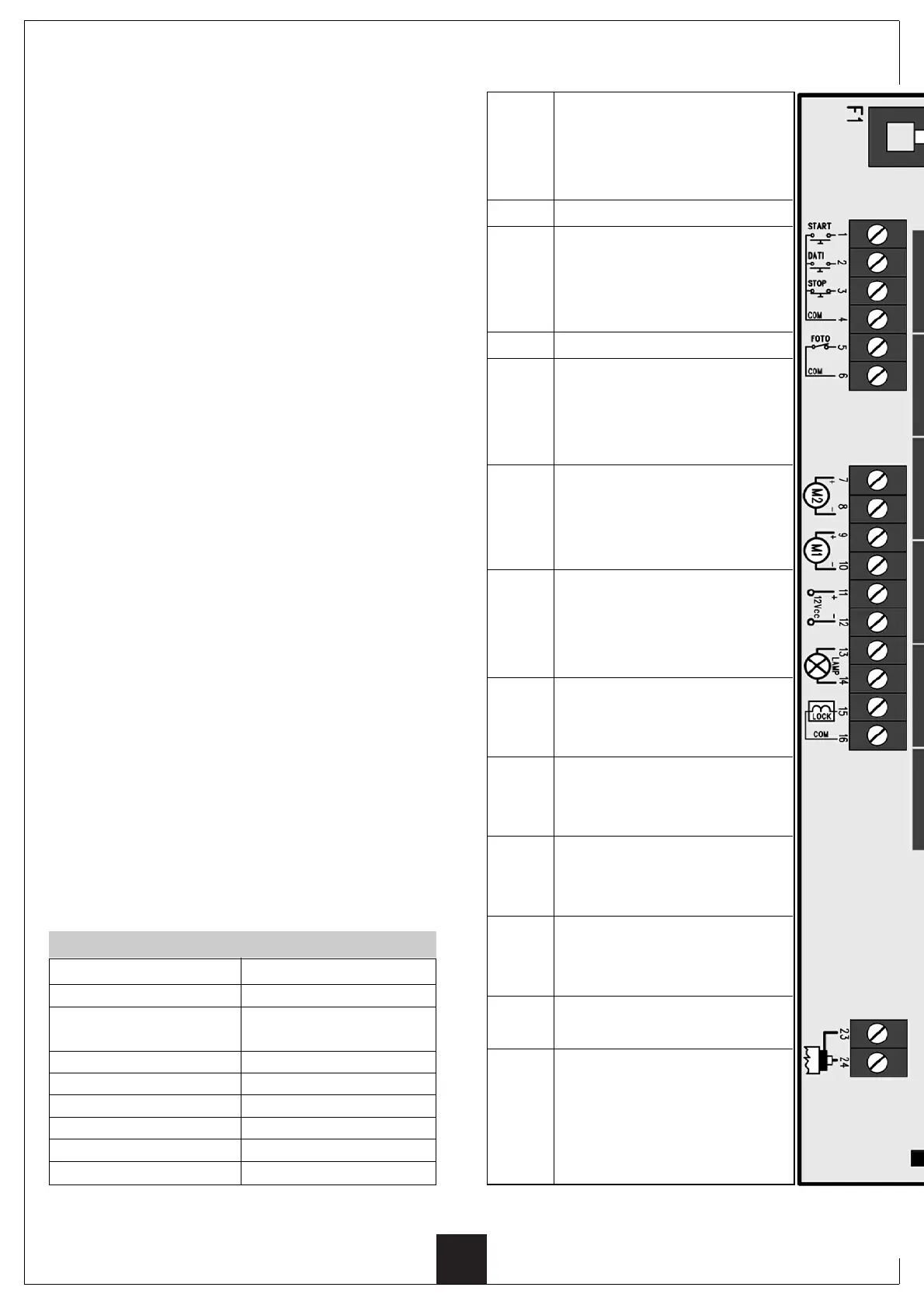

TERMINAL CONNECTIONS

1 - 4

2

3 - 4

4

5 - 6

7 - 8

9 - 10

11 - 12

13 - 14

15 - 16

17 - 18 -

19 - 20 -

21 - 22

23

24

Connect to the START button/s

(it deals with a normal open or nor-

mal closed contact, which can be

programmed by means of switch 5)

UNUSED

Connect to the STOP button

(it deals with a normal closed

contact). If it is not used make a

jumper with the common contact.

COMMON

Connect to the normal closed

contact of the PHOTOCELL. If it is

not used make a jumper with the

common contact.

Connect to the motor 2 according

to the silk screen printing polari-

ties. DO NOT use this output if it

deals with a one-door gate.

Connect to the motor 1 according

to the silk screen printing polari-

ties. Use this output if it deals

with a one-door gate.

Output for the feeding of the

PHOTOCELL). Voltage 12 VDC,

500 mA max. current.

Connect to the signaling blinking

lamp.

Voltage: 12 Volt, lamp: 10 W.

Connect to an electric lock.

Voltage: 12 VDC, 3 A max.

current.

UNUSED

Connect to the antenna cable

shielding.

Connect to the antenna cable cen-

tral connector. Use an antenna

having a 433 MHz rated frequency.

Alternatively, connect a conductor

having a 17cm main insulation.

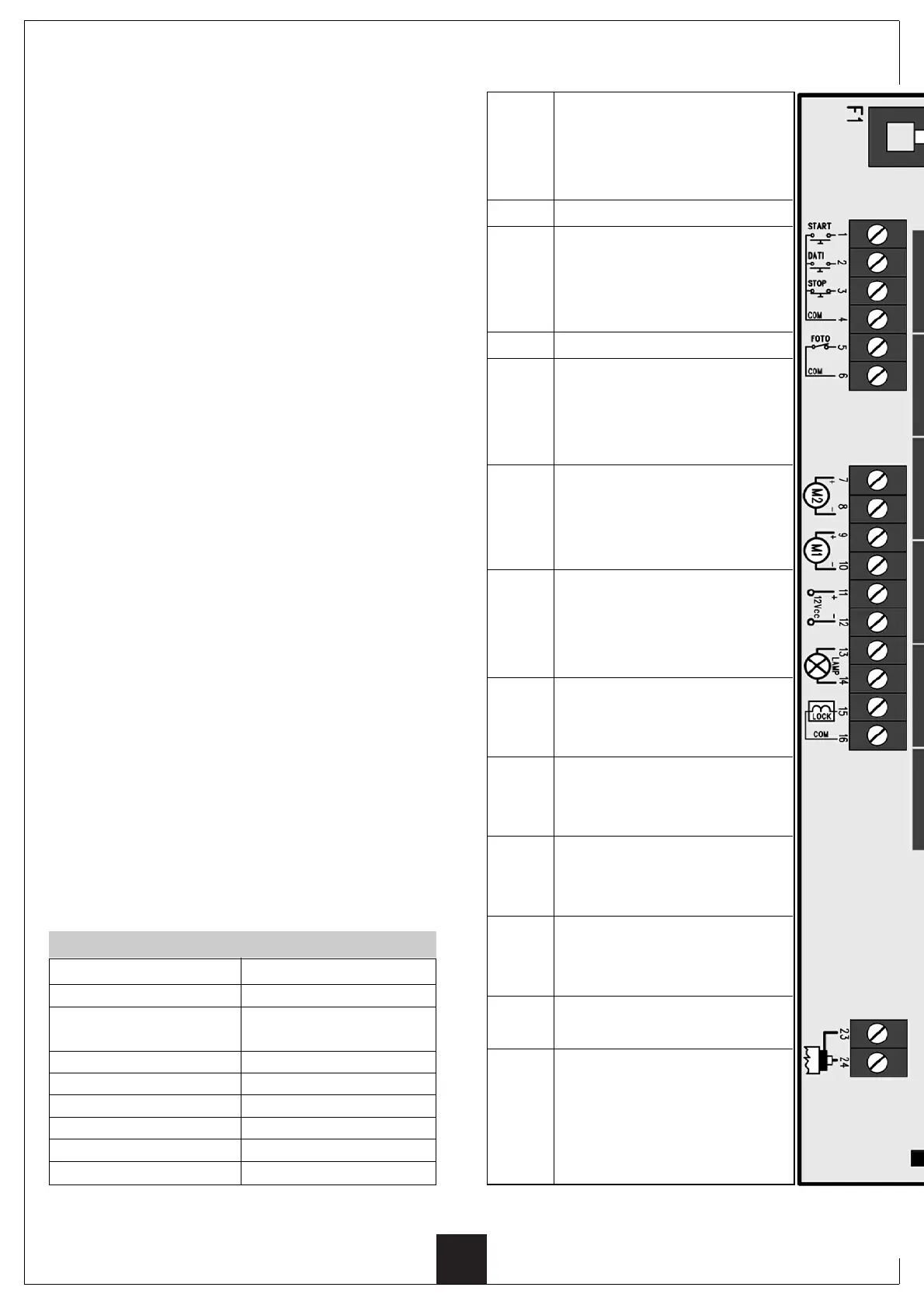

DESCRIPTION OF THE CONTROL UNIT

PRG12PP has been planned to control double- and one

– door gates, driven by means of 12V D.C. actuators.

Benefits resulting from the very low voltage

automations using PRG12PP are as follows:

• No risk of accidental electrification of the metallic

masses which are connected to the power plant

(actuators, doors and accessories).

• Anti-squashing safety, carried out by means of a

stress detector on the motor ensuring the door

movement stop in case the photocells do not detect

the presence of an obstacle.

• No blackout function by means of a lead accumulator

enabling the system operation even if no power is

supplied.

• Door slowing down in the end of stroke area, to

prevent noisy closings and door recoil.

•Time machine auto-learning: during the program

phase, the system carries out a recording cycle

concerning the door opening and closing times, so

simplifying the calibration and adjustment

operations.

The terminal inlets are equipped with the following

components:

• Infrared bearing inlet (PHOTOCELLS).

• Stop button inlet (STOP).

• Opening button inlet (START).

The terminal outputs are equipped with as follows:

• Motor 1 and Motor 2 feeding.

• 12 Volt blinking lamp (max 10 W).

• 12 Volt D.C. accessory feeding.

• 12 Volt D.C. electrolock.

Built-in super-heterodyne 433 Mhz receiver.

This system can record up to 48 Personal Pass

transmitters.

Power supply 230 VAC, 50 Hz

Motors maximum load 60 W

24VAC attachment 10 W

maximum load

Room work temperature -20 ÷ +60 °C

Fuses F1 = 2 A

F2 = 10 A

Dimensions 210 x 275 x 100 mm

Weight 2,5 Kg

Protection IP55

SPECIFICATIONS

Loading...

Loading...