EN-18 452172.66.10-EN · FD 0311 www.dimplex.de

English LIA 0608BWCF M - LIA 1316BWCF M

º

If the indoor unit is mounted 4 m or more metres higher or

lower than the outdoor unit, a cooling technology specialist

must perform a separate check to ensure that the devices for

conveying the oil up and down the pipes have been installed

correctly in the split line.

º

The rated output of the device may vary depending on the

split line length.

!

Incorrect filling with refrigerant could lead to faults during

operation.

1) Production operation (see model name label)

2) Installation operation (where possible, attach alongside the

maintenance connections for adding or removing refriger-

ant)

3) Total filling (1, + 2,)

!

If the filling quantity changes, document it in an easily visible

place (e.g. filling quantity on the type plate). Do not add more

than the specified amount of refrigerant to the system.

7.1.2 Preparation for pipework

The preparation of the pipework takes place in five steps. One

main cause of refrigerant leaks is incorrect flanging. Flanging

must be carried out carefully and according to the following

steps.

Step 1: Cutting pipes and cables

Use the installation kit for pipework or the pipes purchased

from your local dealer.

Measure the distance between the indoor and outdoor

unit.

Cut the pipes slightly longer than the measured distance.

Step 2: Removing burrs

Remove all burrs from the interface of the pipework.

Hold the pipe end downwards so that no burrs can fall into

the pipe.

Step 3: Inserting screw nuts

Remove the screw nuts on the outdoor unit.

Insert the screw nuts into the deburred pipe.

No nuts can be inserted into the pipe after flanging.

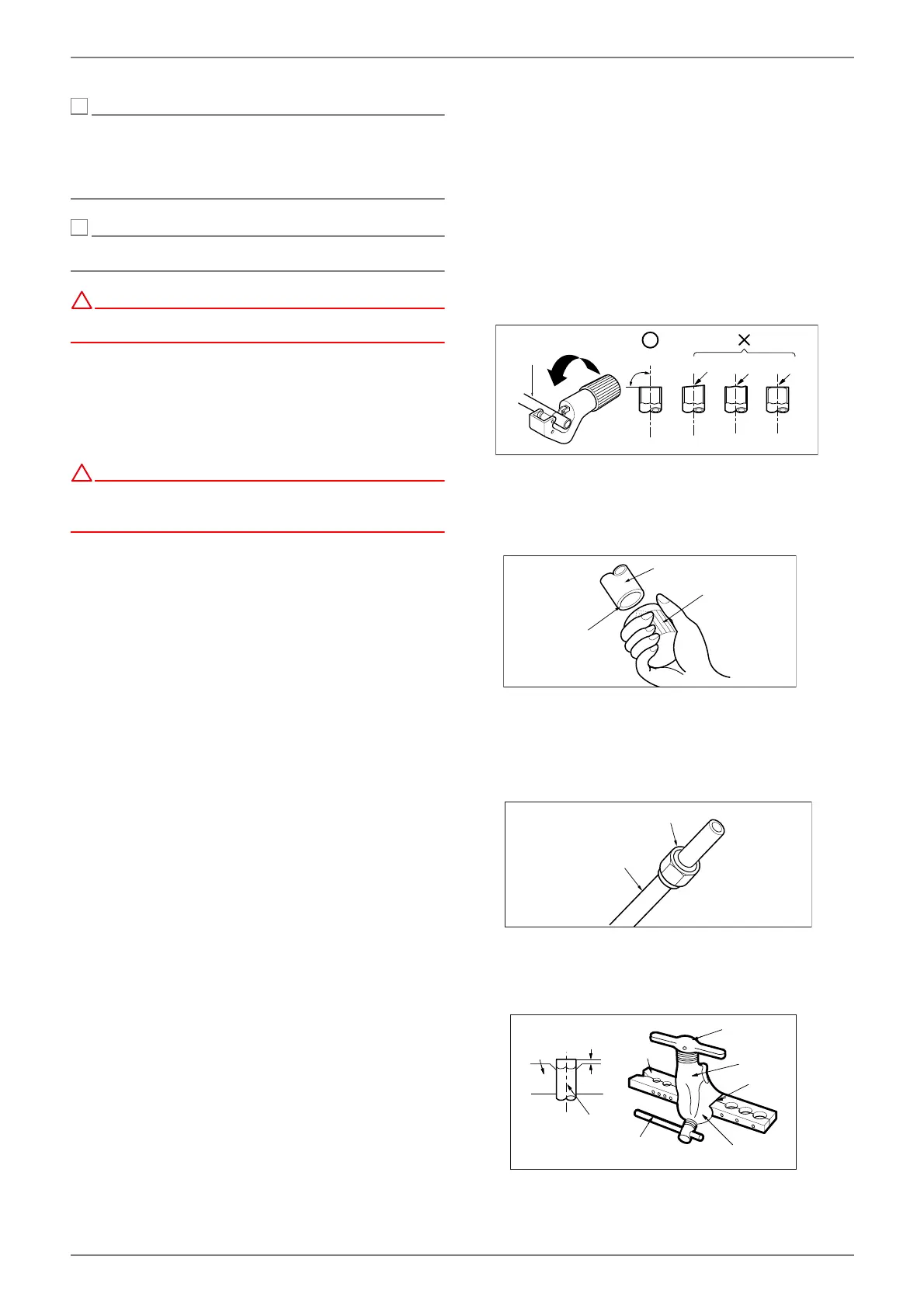

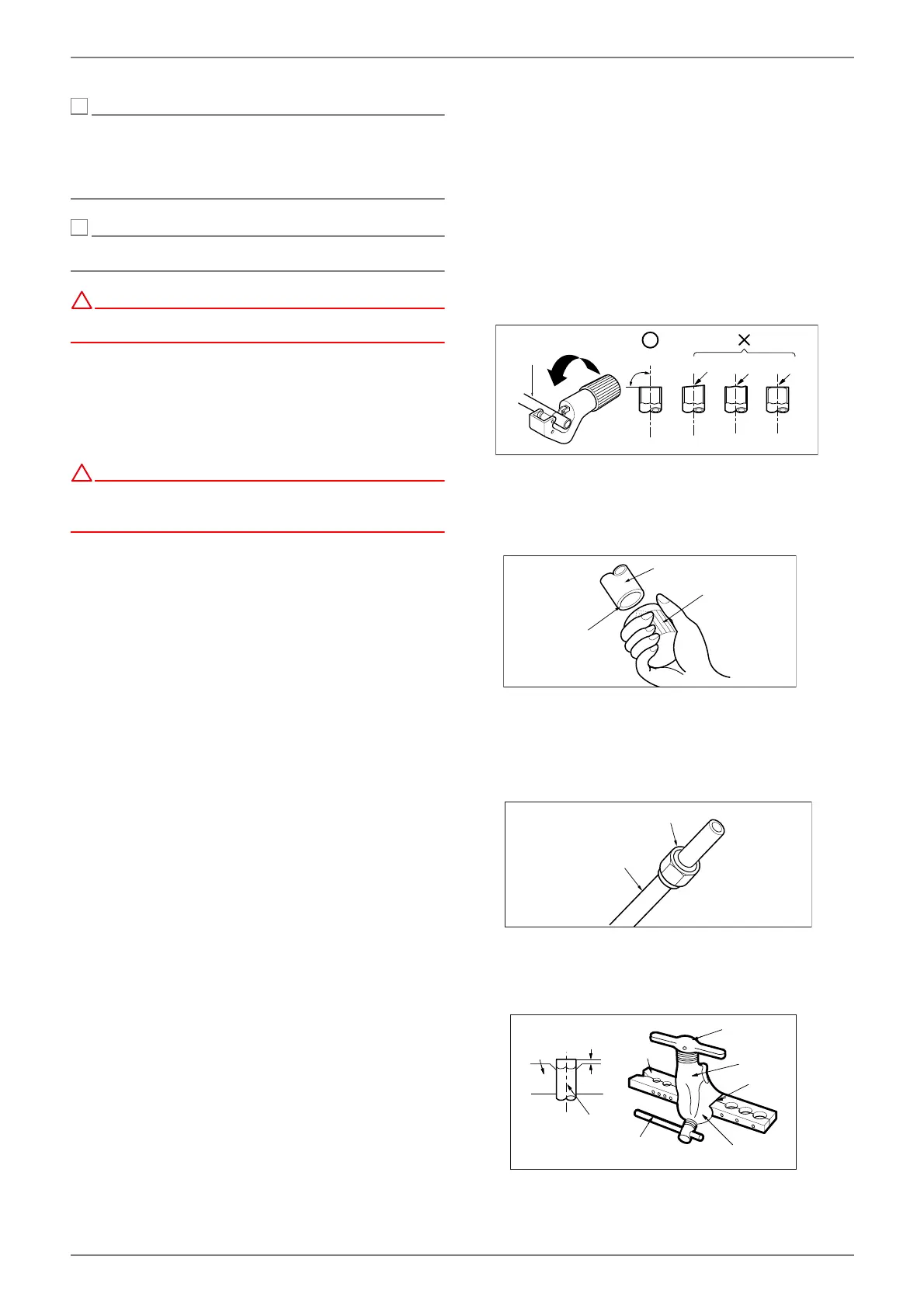

Step 4: Flanging

Flanging must be carried out as follows with a flanging tool

for R32 refrigerant as shown in the figure.

&RSSHUSLSH

90q

Tilted Uneven Raw

3LSH

Reamer

Hold facing

downwards

5DLO

Copper pipe

Clamp

Red arrow marking

Cone

Bracket

Handle

Rail

"A"

Loading...

Loading...