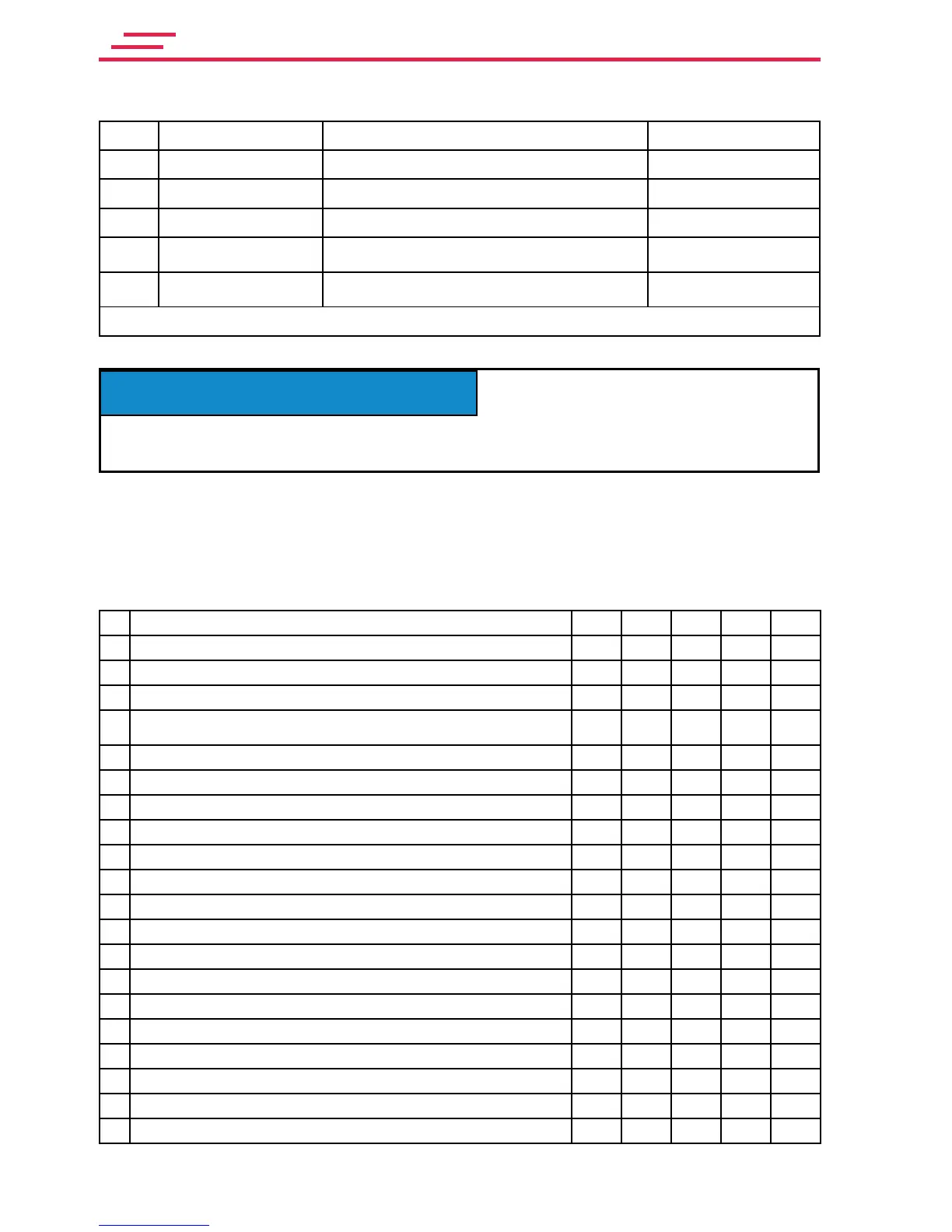

2. SERVICING AND MAINTENANCE

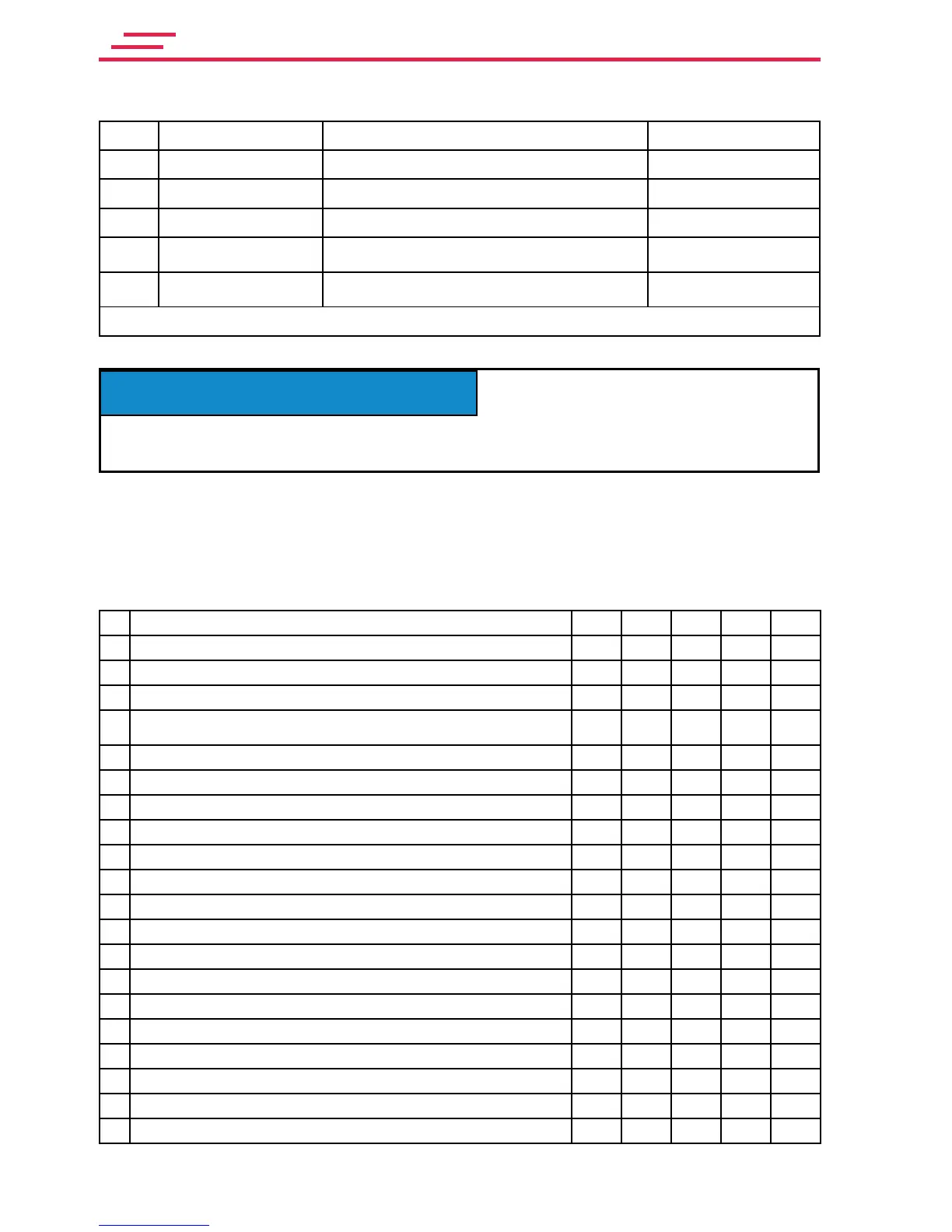

Maintenance item A B C D E

1

Condition of chassis structures, boom and work platform C C C I

2

Bearings of the overload protection device joint G C/G C/G

3

Bearings of outriggers and outrigger cylinders G C/G I/G

4

Bearings of outrigger footplates and moving parts of outrigger limit

switch system

G C/G I/G

5

Bearings of boom and articulated arms G C/G C/G

6

Bearings of the platform G C/G C/G

7

Bearings of the levelling cylinders G C/G C/G

8

Bearings of the lifting cylinder G C/G C/G

9

Sliding surfaces / rolls of the telescope C/G C/G C/G

10

Axles G G I/G

11

Track rod bearings G C/G C/G

12

Bearings of the telescope cylinder C/G C/G

13

Condition of cylinders I

14

Flyer-chain G I/G

15

Slide pads and sliding pad clearances C C C

16

Turning device G I/G

17

Electro-hydraulicrotatingadaptor C

18

Tyres and tyre pressures C C I I

19

Drive functions C C

20

Lights C C C I

NOTICE

In addition to daily maintenance, every user must do a worksite inspection before operating

the lift.

C=Check(generalcheckingofcondition).

I = Thoroug Inspection. Performed according to separate prochedure described in

maintenance instructions.

G = Grease

D = Do the replacements, repairs or other maintenance tasks described in the isntructions

Maint. Schedule Person responsible Reference

A

Daily Operator Operating instructions

B

1 month / 100 hours* Competent person who is familiar with the lift Maintenance instructions

C

6 months / 500 hours* Competent person who is familiar with the lift Maintenance instructions

D

Annually / 1000 hours*

Skilled technician who is well familiar with the

structure and operation of the lift

Maintenance instructions

E

As needed

Skilled technician who is well familiar with the

structure and operation of the lift

Maintenance instructions

*Servicemustbeperformedeveryindicatedmonthoroperatinghourinterval,whichevercomesrst.

Loading...

Loading...