4. PERIODIC SERVICE

Periodic service shall be done according to these instructions. These maintenance and

service prochedures shall be performed by competent maintenance personnel.

4.1. INSTRUCTIONS FOR MONTHLY SERVICE AND INSPECTION

Always do all daily inspections in addition to monthly service tasks.

Ifyounoticeanyaws,defectsordamagetothelift,takenecessarycorrectiveaction.

It is strictly prohibited to use a lift which is out of order.

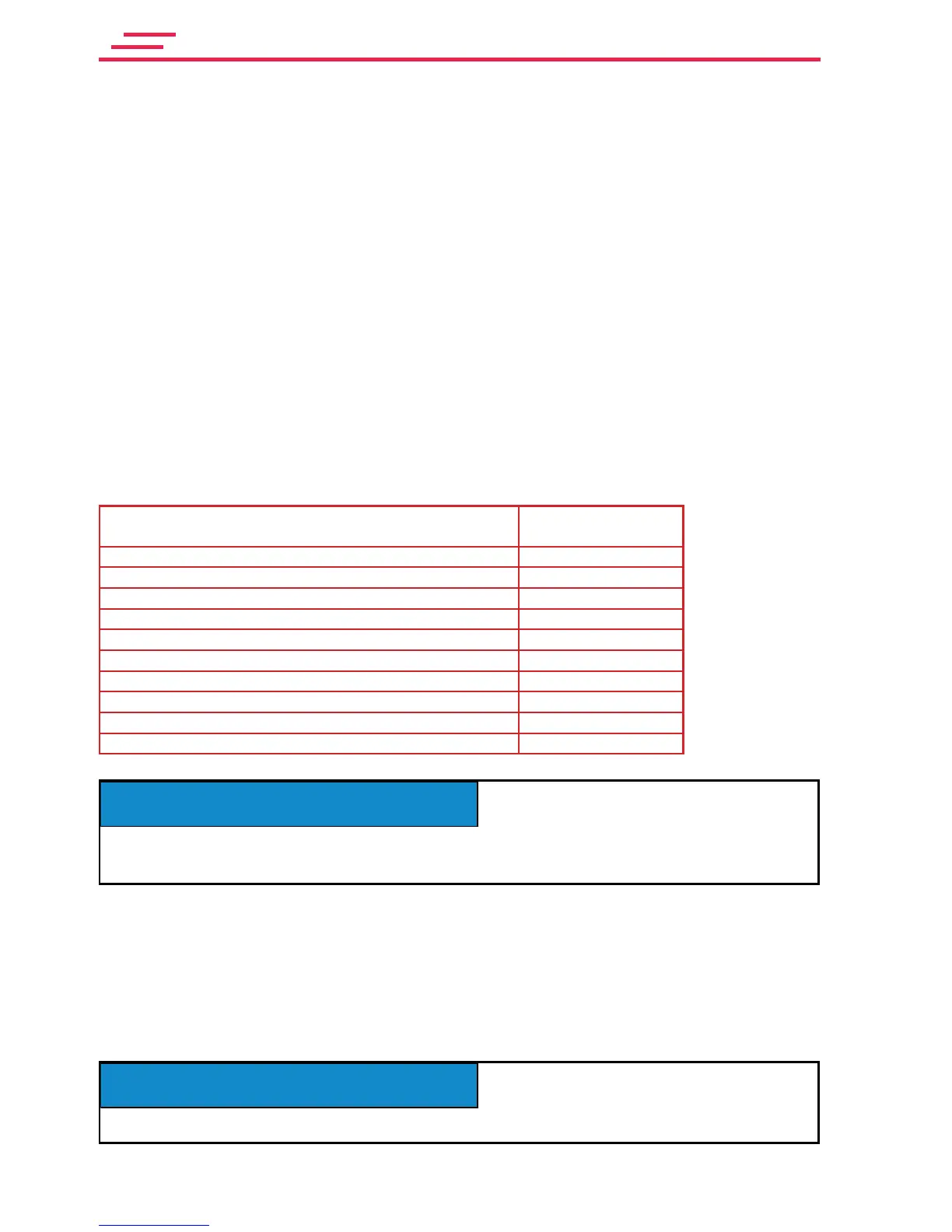

4.1.1. Lubrication of necessary parts

Maintenanceitems2-11.Greasenipplepositionsareshowninthelubricationplanandthey

are marked with labels on the lift.

Add new lubricant until the grease coming out of the joint is clean. Wipe off excess grease if

necessary.

Lubricant: Esso Beacon EP2 or equivalent.

Sliding surfaces of the telescope are lubricated with silicone.

Number in

lubrication plan

Bearings of the safety device 1

Bearings of the outriggers and outrigger cylinders 2 ja 3

Bearings of the outrigger foot plates 4

Bearings of the boom and the articulated arms 5

Bearings of the platform 6

Bearings of the levelling cylinders 7

Bearings of the lifting cylinder 8

Sliding surfaces/rolls of the telescope 9

Bearings of the oscillating axle 10

Track rod bearings 11

NOTICE

Theoverloadprotectiondevicejoint(point1)mustabsolutelybelubricatedregularlyand

always immediately after the lift has been washed..

4.1.2. Check the slide pads and sliding pad clearances

Check the clearance between the slide pads and sliding surfaces and adjust the pads if

necessary. The pads should be adjusted so that the boom extensions are centered and

do not scrape to the edges. The clearance between slide pad and sliding surface must be

minimal but the pads should not squeeze the boom extension.

Loading...

Loading...