DOLD GMBH Operating instructions DMP 96 A

DMP 96 A Version: 020 Number of pages: 26

H0e020bA4.doc Edition: 07.11.2006

24

Display: Parameter:

"SEn" Sensor ID as in table

Sensor ID:

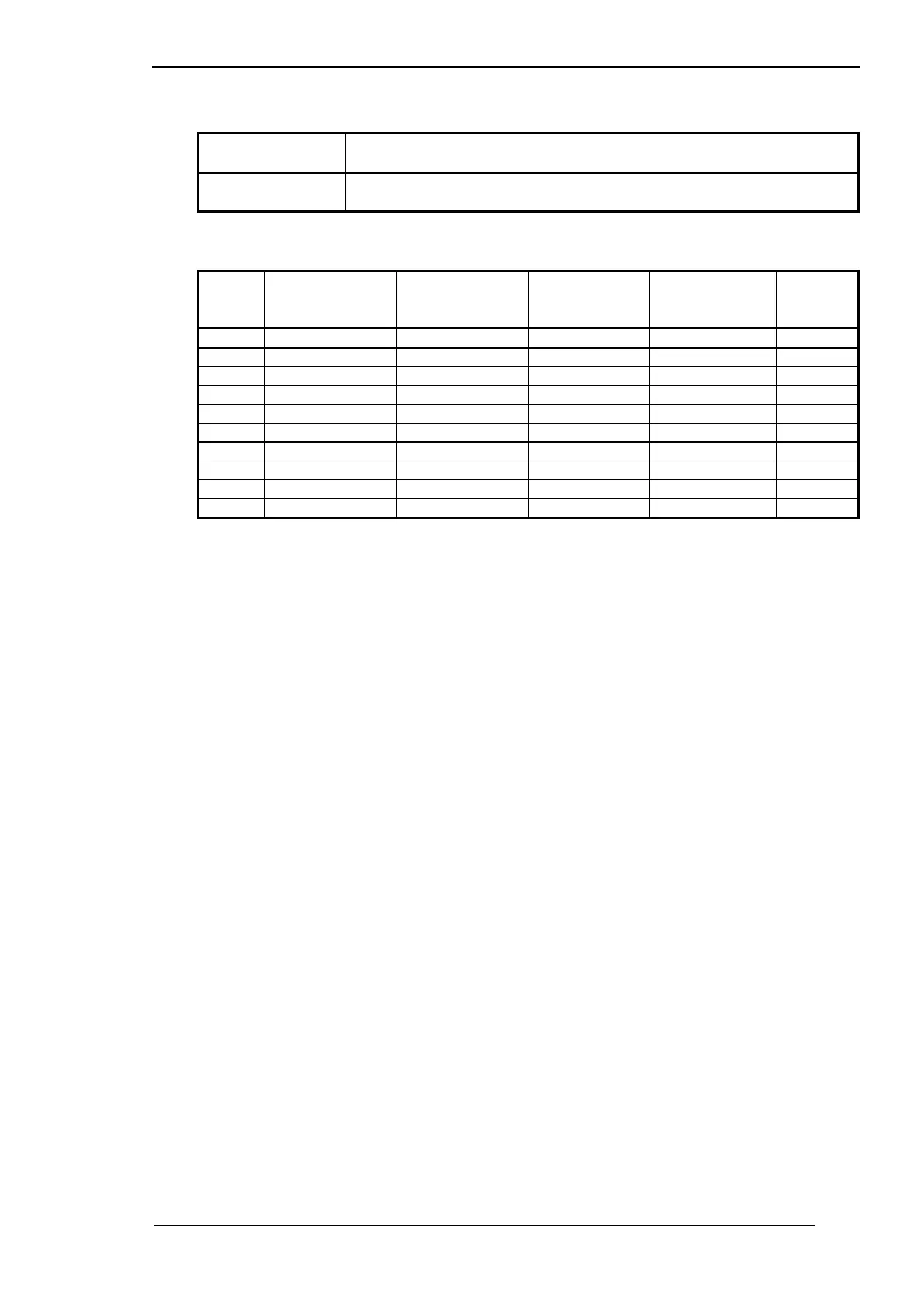

Sensor

ID:

ID by ordering

key:

Sensor: Max. display

range:

Max. setpoint

range:

Display:

P 1 P 1 Pt 100 -69...149°C -50...100°C 3 digits

P 2 P 2 Pt 100 -69...249°C -50...200°C 3 digits

P 3 P 3 Pt 100 -69...349°C -50...300°C 3 digits

P 4 P 4 Pt 100 -69...699°C -50...600°C 3 digits

P 5 P 5 Pt 100 -169...149°C -150...100°C 4 digits

tL1 L 1 Fe-CuNi Type L -24...499°C 0...450°C 3 digi ts

tL2 L 2 Fe-CuNi Type L -24...899°C 0...850°C 3 digi ts

tn1 K 1 Ni Cr-Ni Type K -24...649°C 0...600°C 3 dig its

tn2 K 2 Ni Cr-Ni Type K -24...1299°C 0...1200°C 4 d igits

8. Line compensation, zero-point offset:

8.1 Line compensation:

Line compensation is required only with resistance thermometers in two-wire technology. Line

resistance can be counterbalanced with the "Cor" parameter (configuration level).

Proceed as follows to generate line compensation:

1. Connect a 100 Ω resistor to the end of the sensor line (corresponds to 0°C).

2. Read off the actual value from the display.

3. Jump to the configuration level.

4. Correct line resistance (display in °C) with the "Cor" parameter.

Example: 1. Displayed actual value: +3.0°C

2. "Cor" value to be set on the configuration level: -3.0°C

3. Confirm the set value with the P key.

Return to operating mode

4. Display of actual value: 0.0°C

5. Remove 100 Ω resistor from end of line.

8.2 Zero-point offset:

The "Cor" parameter can also be used for zero-point offset (offset value) towards plus or minus

(as in the above example).

Loading...

Loading...