DOLD GMBH Operating instructions DMP 96 A

DMP 96 A Version: 020 Number of pages: 26

H0e020bA4.doc Edition: 07.11.2006

20

P

Jump to parameterization level.

Depending on the configuration of the outputs (configuration level) only those parameters are

accessible which are needed for the specific function.

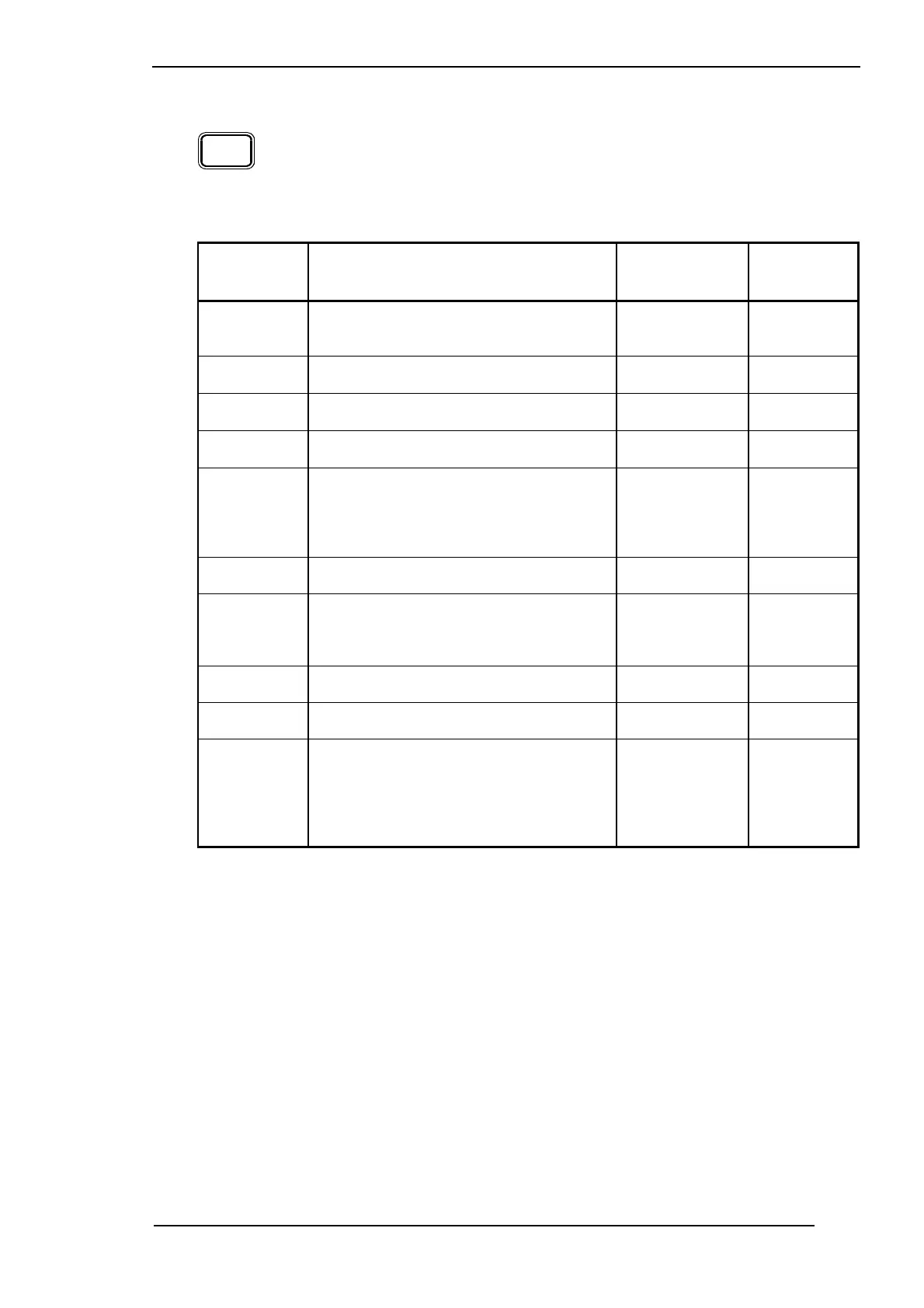

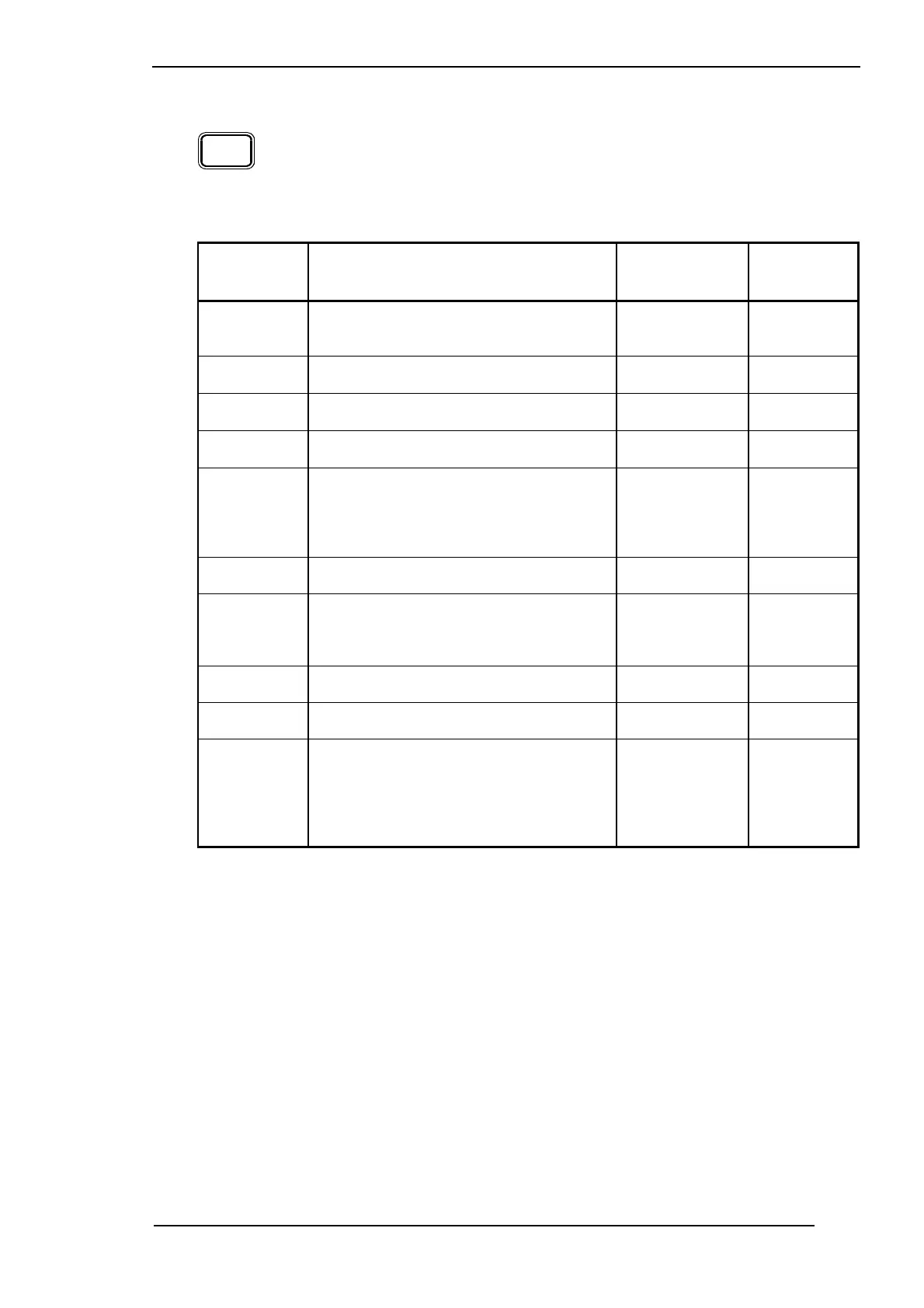

Display: Parameter: Range: Factory

setting:

"Pb.1" Proportional band, control contact K 1

(Pb = 0.1...200% relative to setpoint ran

according to sensor ID, Section 2.1)

0.1...200%

"Co.1" = 02, 05

5.0%

"ti.1 " Reset time, control output K 1

(adjustment zero = time 0)

0...999 s

"Co.1" = 02, 05

250 s

"td.1" Derivative action time, control output K 1

(adjustment zero = time 0)

0...500 s

"Co.1" = 02, 05

50 s

"CY.1" Cycle time, control output K 1 1...200 s

"Co.1" = 02, 05

30 s

"HY.1" Hysteresis, control output K 1 0.1...5% of set-

point range limit

dependent on

sensor ID

"Co.1" = 01, 04

1.0 K

"bd.1" Symmetrical spreading, limit comparator

K 1 (hysteresis fix at 0.5 K)

0.1...99.9 K

"Co.1" = 03, 06

5.0 K

"LA.2" Absolute setpoint, limit-value contact K 2 max. display ran-

ge dependent on

sensor ID

"Co.2" = 01, 04

0.0 °C

"Lr.2" Spreading, limit-value contact K 2 travel-

ing with setpoint

-99...99.9 K

"Co.2" = 02, 05

0.0 K

"bd.2" Symmetrical spreading, limit comparator

K 2 (hysteresis fix at 0.5 K)

0.1...99.9 K

"Co.2" = 03, 06

5.0 K

"HY.2" Hysteresis, limit contact K 2 0.1...20% of set-

point range limit

dependent on

sensor ID

"Co.2" = 01, 02,

04, 05

1.0 K

7.6 The self-optimization level:

The DMP 96 A controller is equipped with an optimization routine for the automatic adaptation of

the controller to the controlled system.

The optimization algorithm is based on modified Ziegler-Nicols rules, according to which the cha-

racteristic data of the system are calculated after an oscillation test in a closed-loop control cir-

cuit.

These characteristic data (particularly period and amplitude of oscillation) form the basis for cal-

culating specific parameters.

Depending on the control function (heating controller or cooling controller), parameters are calcu-

lated for either the heating or the cooling side.

Loading...

Loading...