7

EN

VARC Chiller Controls General Information

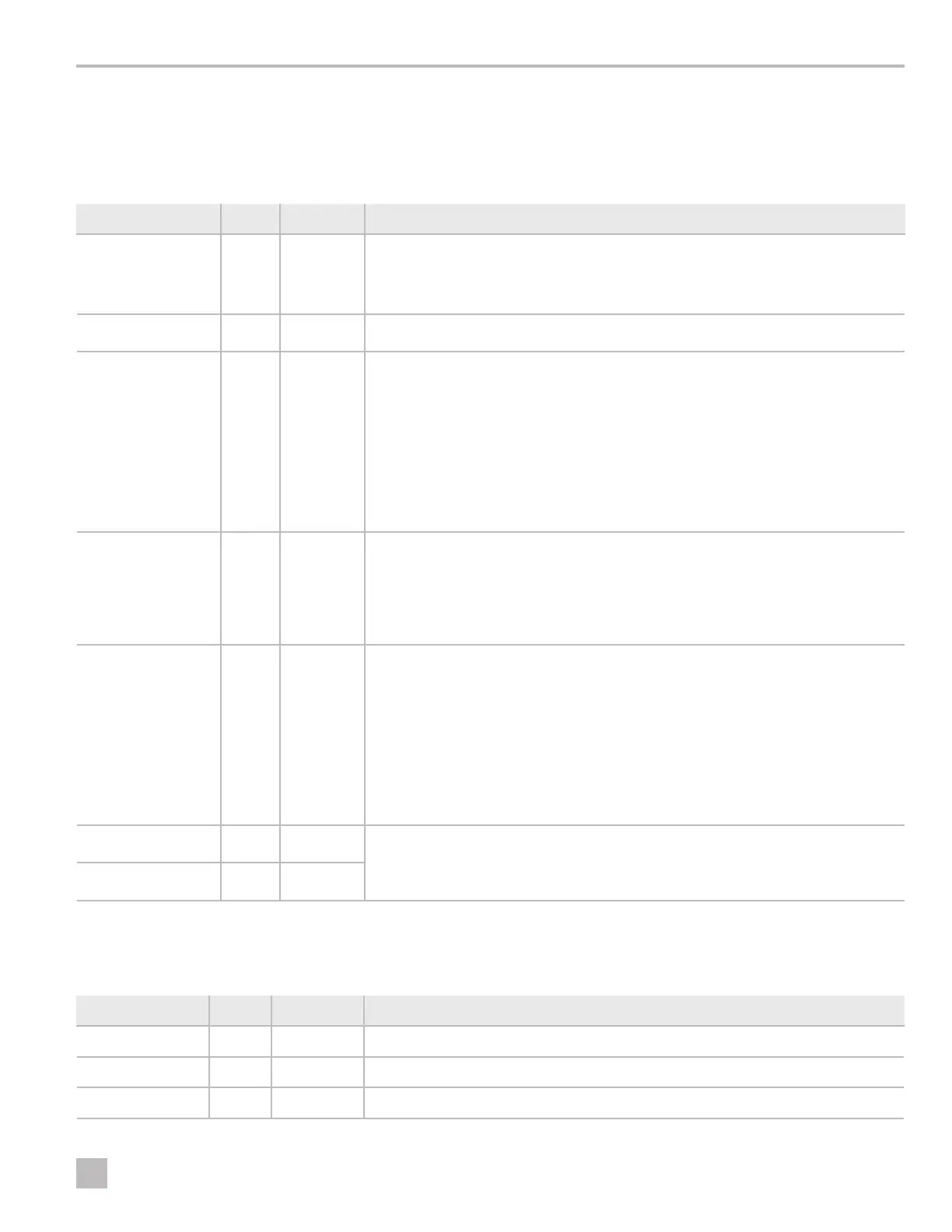

2.2.2 Digital Inputs

Digital inputs are used to monitor the status of the VARC protection circuits. At powerup, all discrete inputs are checked

before the system is enabled. Any faults detected on startup must be verified and cleared via the VARC before the system

will start normal operation. For information on clearing alarms, see “Viewing Alarms for Each Stage” on page 28.

Input I/O # Board I/O Description

Refrigerant High Side

Pressure Limit

DI-1 DI-1 If the high pressure switch is tripped and turns off the compressor, the VARC acknowledges

an open circuit and generates a High Discharge Pressure fault. The VARC will not allow the

compressor relay to be re-energized until the high pressure switch is in the closed position.

You must acknowledge and clear the fault prior to re-enabling the VARC or the disabled

stage. See “Viewing Alarms for Each Stage” on page 28.

Econo Mode Selection DI-2 DI-2 This optional input is used to put the VARC into Econo mode. While Econo mode is enabled

by this input, the VARC cannot be put into Normal or Boost mode.

Chilled Water Flow

Switch

DI-3 DI-3 With the VARC in either Heat or Cool mode, the Flow switch must be closed prior to system

starting or a stage being enabled. In operation, if flow is lost for more than 10 consecutive

seconds, the following occurs:

• The compressor or heat relay is disabled for the stage that has lost flow.

• A Chilled Water Flow fault is generated.

• The VARC goes into lockout.

• A manual restart is required, aer the system initiates, retries, and fails or exceeds timeout.

You must acknowledge and clear the fault prior to re-enabling the VARC or the disabled

stage. See “Viewing Alarms for Each Stage” on page 28.

Load Shedding Input DI-4 DI-4 The load shedding standard input is activated with a 230 V signal. When load shedding

becomes active, the VARC shuts off the compressor and maintains that state until the load

shedding input is disabled.

In a multi-stage operation, load shedding shuts down the stage with the highest run hours.

Every unit has a load shed input. The number of load shedding signals received (one per unit)

determines how many units are shut off according to run hours.

Electric Heat (E. H.)

Flow Switch

DI-5 DI-5 This optional switch is enabled through the factory settings. With the VARC in either Heat or

Cool mode, the Flow switch must be closed prior to system starting or a stage being enabled.

In operation, if flow is lost for more than 10 consecutive seconds, the following occurs:

• The electric heat is disabled for the stage that has lost flow.

• An Electric Heat Flow fault is generated.

• The VARC goes into lockout.

• A manual restart is required, aer the system initiates, retries, and fails or exceeds timeout.

You must acknowledge and clear the fault prior to re-enabling the VARC or the disabled

stage. See “Viewing Alarms for Each Stage” on page 28.

Cool Mode Selection

Switch

DI-6 DI-6

These switches allow for remote mode control. When using digital input mode selection, the

display cannot be used to change mode, but all other functions on the display are available.

Heat Mode Selection

Switches

DI-7 DI-7

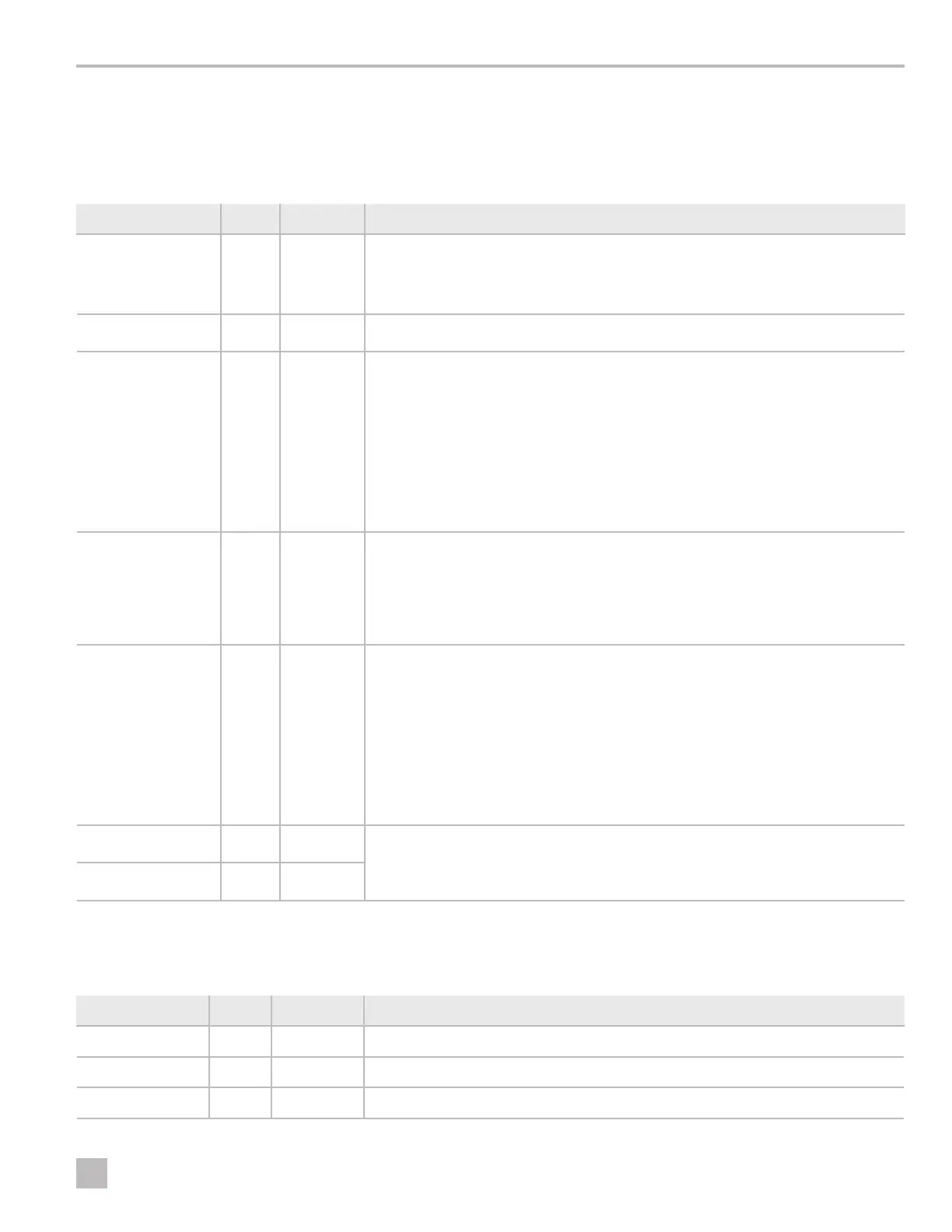

2.2.3 Digital Relay Outputs

I

If a temperature sensor is defective or not connected, the VARC generates an alarm for that sensor.

Output I/O # Board I/O Description

SWP DO-1 NO1 Provides switched power to the contactor coils for the Sea Water Pump.

CWP DO-2 NO2 Provides switched power to the contactor coils for the Chilled Water Pump.

Reversing Valve (RV) DO-3 NO3 Provides switched power to the coils for the Reversing Valve.

Loading...

Loading...