D439E Service Manual 2. Engine Mechanical System (D439E)

18

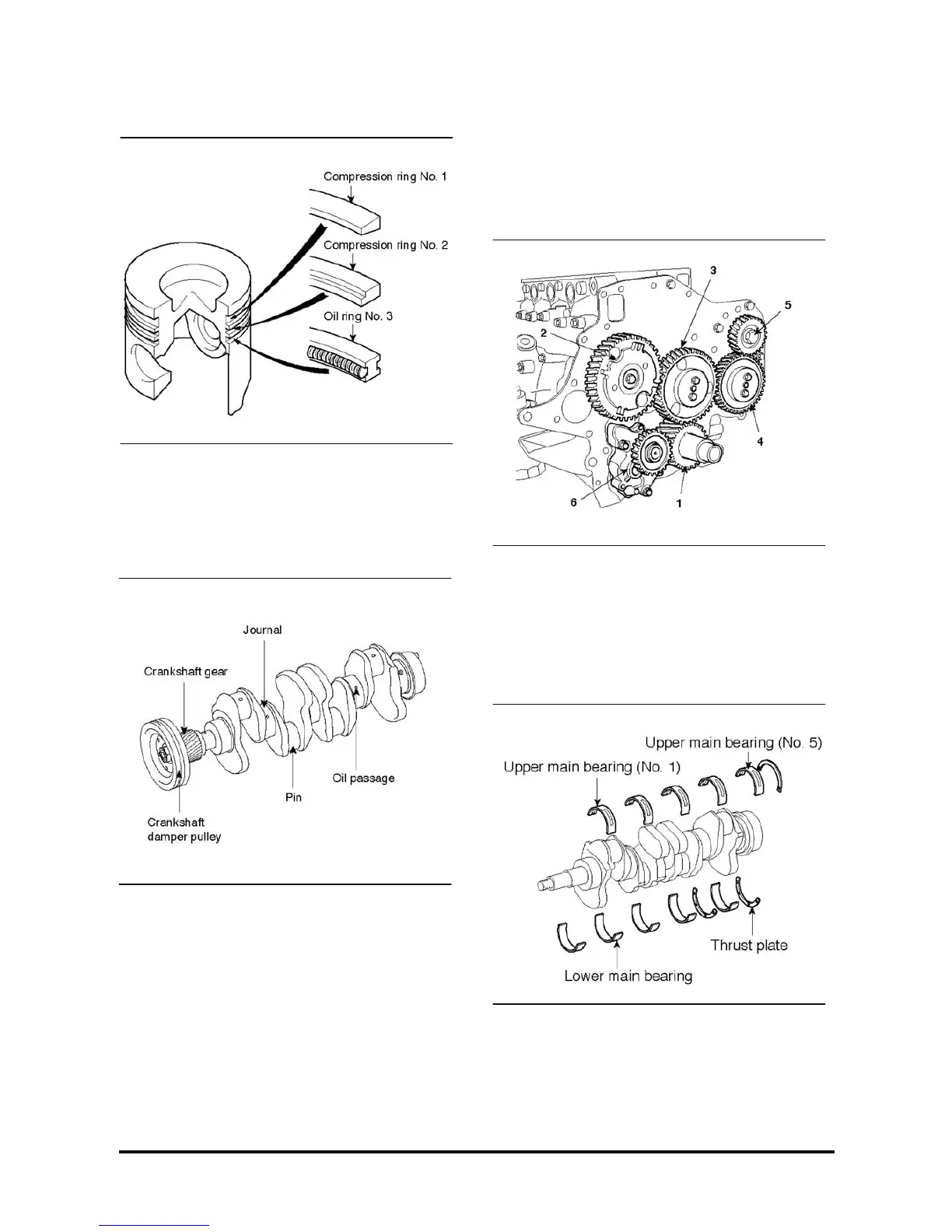

Piston Ring

Piston has two compression rings and one oil ring.

All sliding surfaces of rings are coated with

hardened chrome.

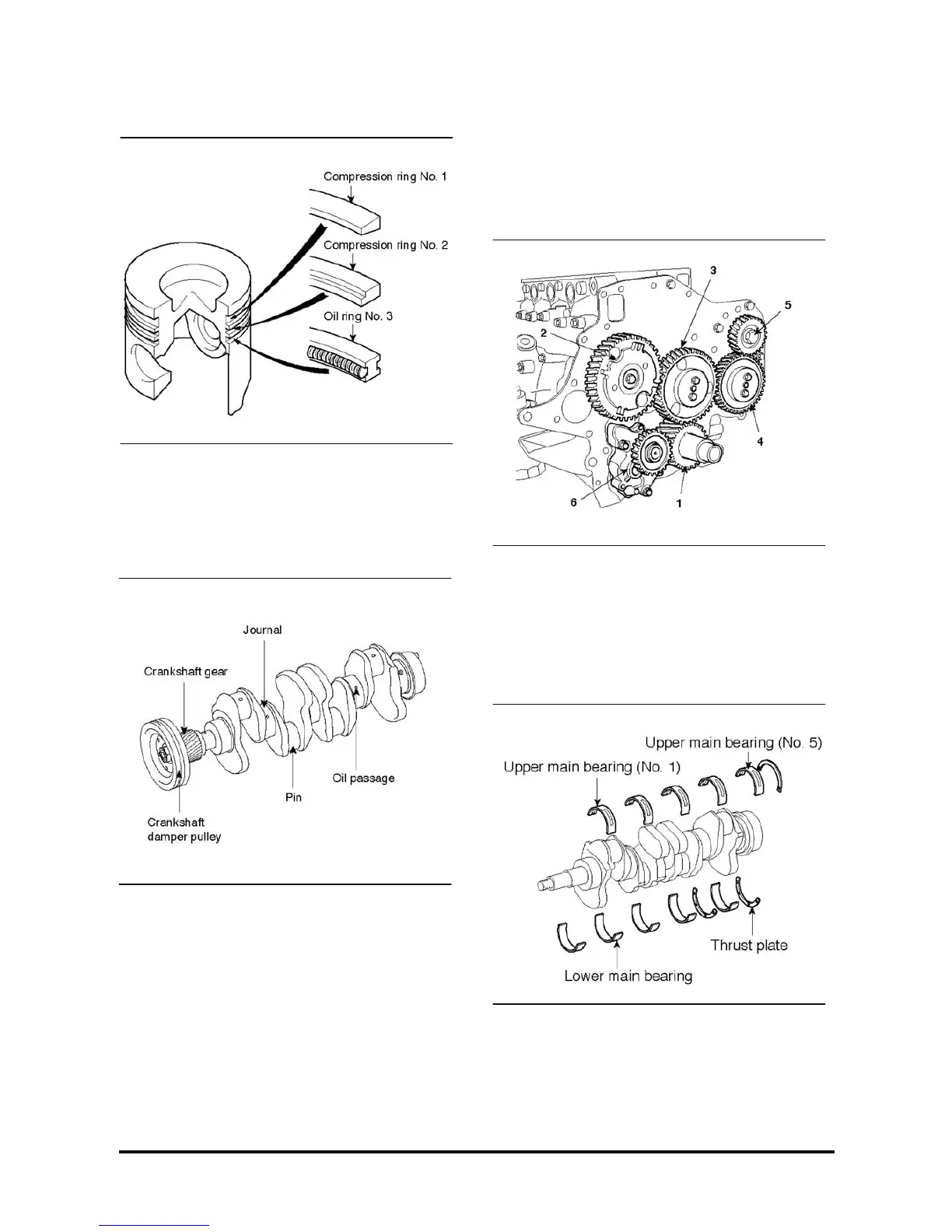

Crankshaft

1. Crankshaft is forged with high-strength alloy built

in with balance weight.

2. Pin, journal and oil seal sliding-surface are

hardened with high frequency heat treatment to

raise the resistance against frictional wear.

3. Through oil passage at the pin and journal, oil

lubricates main bearing. Oil flows to the pin for the

lubrication of connecting rod bearing.

4. Crankshaft pulley and crankshaft gear are

installed at the front end of crankshaft. The

crankshaft pulley drives alternator and water

pump using V-belt.

5. Crankshaft damper pulley absorbs the distorting

vibration of crankshaft.

6. Crankshaft gear (1) drives camshaft gear (2), idler

gear A (3), idler gear B (4), supply pump gear (5)

and oil pump gear (6).

Crankshaft Main Bearing

Upper main bearing has oil groove and oil hole

which matches with oil hole of the crankshaft.

Divided type thrust plate is Installed to the both ends

of the last bearing (N0.5).

Loading...

Loading...