7.4 Performing a teach-in run

The teach-in run must be carried out while the motor

is cold. The door panel may not be moved manually

and stopped during the teach-in run. The control unit

would otherwise not be able to correctly determine the

parameters.

The safety sensors and activators are shut off during

the teach-in run so that they do not interfere with the

teach-in process.

The smoke detector and the shutdown drive function

are active.

1. Secure the movement range of the door panels.

2. Close the door and turn the program switch to the OFF

position.

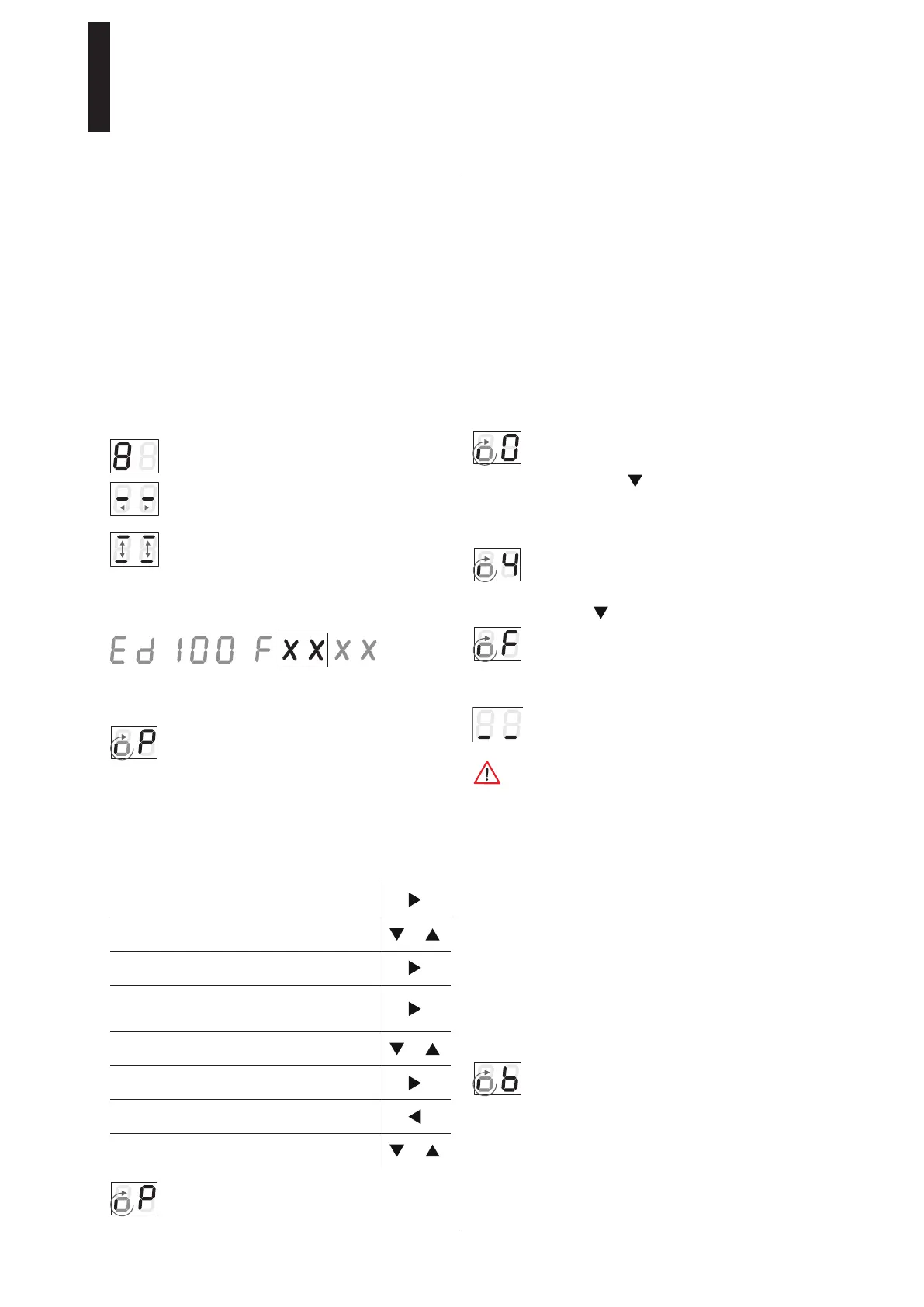

A spinning “o“ and “O“ indicate that a teach-in

run is required.

3. Press the pushbutton for 3 seconds.

► The door performs various movements and the display

shows a sequence of characters.

Do not stop the movements of the door panel.

The door is in the 70° position and waiting for the

opening width to be set.

4. Push the door to the desired open position and press

the pushbutton .

In case the spring force is too low, the display will

show the small spinning “o“ and “F“.

5. In this case, increase the spring force and restart the

teach-in run.

The door is now operational.

Due to system tolerances, the actual forces on the door

panel have to be measured after the teach-in run and

adjusted, if necessary, in order to comply with the local

standards and regulations.

7.5 Commissioning of a 2-panel system

1. Commssion the active panel.

2. Switch the program switch to PERMANENT OPEN after

the teach-in run.

3. Commission the inactive door panel.

Additional parameterization

• On the active panel:

Set parameter >dL< (door type) to “1“.

Set parameter >Ad< (caster angle) to the set value.

• On the inactive panel:

Set parameter >dL< to “2“.

7.6 Zero point search after mains reset

During the zero point search, the display will show

the small spinning “o“ and “b“.

7.7 Commissioning with integrated smoke detector

cf. mounting instruction ED Cover Basic RM,

ED Cover VARIO RM.

7. Commissioning

(also after a reset with factory setting (Fact-Setup))

7.1 Requirements

• The drive unit is completely installed and correctly

connected to the door panel.

• The parts delivered separately such as the program

switch and activator (microwave detector, night/bank

key switch) are installed and connected.

• The motor is cold.

7.2 Commissioning the drive unit

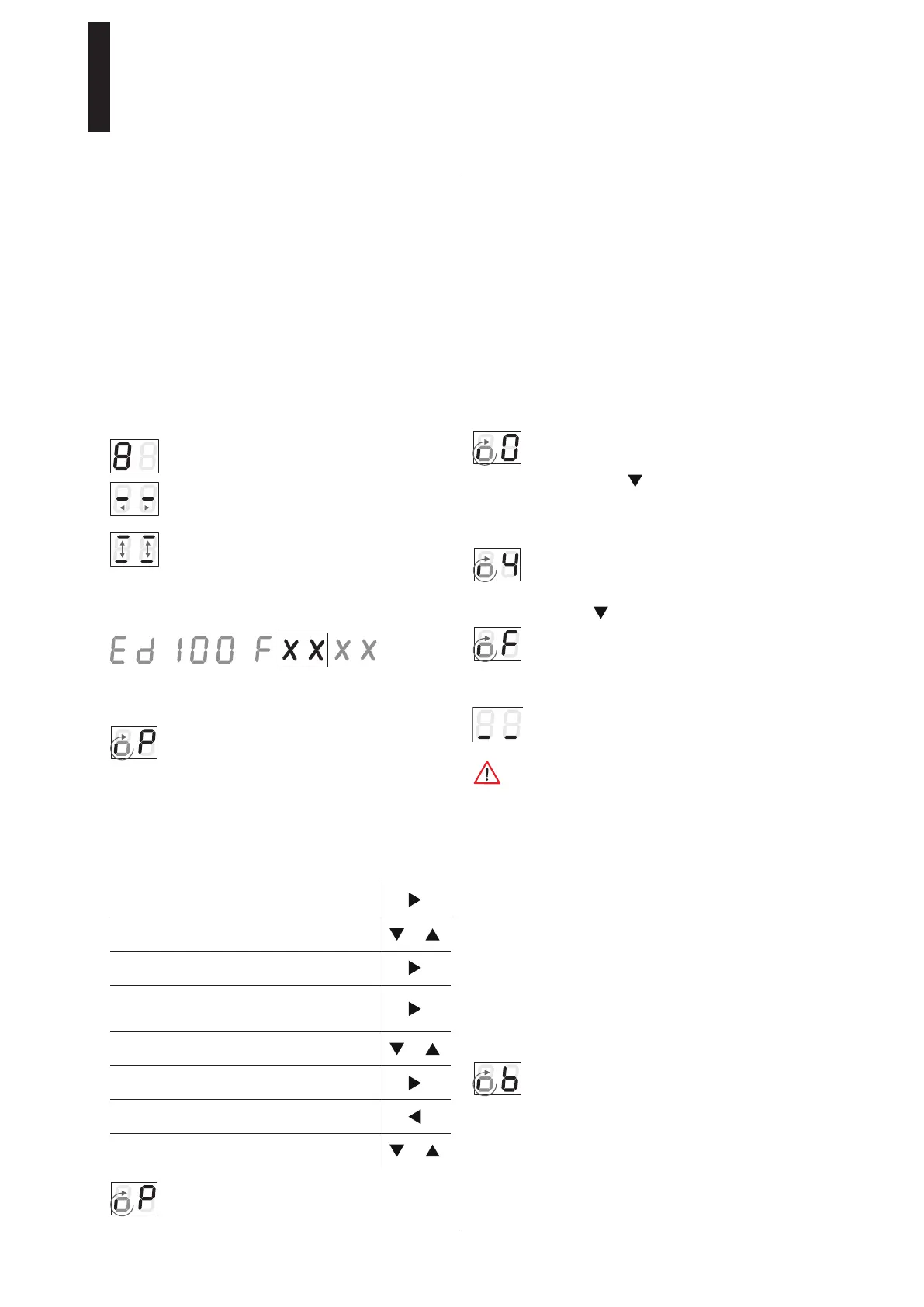

1. Turn on the drive unit using the mains switch.

► The display shows a sequence of characters that

indicate the current processing status.

The system is being tested.

2 segments in the center moving back and forth

indicate that the control unit is waiting for internal

signals (maximum 1 second).

2 underlines moving up and down indicate the

mounting position can be entered. In case of an

incorrect input, the characters on the display are

upside down.

2. Press the lower pushbutton

(possible only during the initial commissioning).

The device identification will “run“ through the

display. ED 100 or ED 250 and the firmware

version (indicated by XX XX).

A small, spinning “o“ and “P“ indicate that a

further parameterization is required (only during

the initial commissioning or after a reset with

factory setting).

3. Set the following parameters: type of mounting (AS),

lintel depth (rd) and door width (Tb).

For the meaning and the value ranges of the

parameters, please refer to the table on page 34.

7.3 Changing the parameters

1. Press the pushbotton for 3 seconds in

order to call up the parameter menu.

2. Press the pushbuttons in order to select

the desired parameter.

or

3. Press the pushbutton in order to display

the parameter value.

4. Press the pushbutton in order to select

the value for the change.

=> The value flashes.

5. Press the pushbuttons in order to set the

desired value.

or

6. Press the pushbutton in order to save the

changed value.

7. Press the pushbutton in order to return to

the parameter menu.

8. Press the pushbuttons in order to select

the next parameter.

or

After leaving the parameterization mode, the

display will show a small, spinning “o“ and “P“.

ED 100, ED 250

—

31

Loading...

Loading...