3.2.4 Wind load control

The drive units ED 100 and ED 250 are especially suited for

external doors that are exposed to changing wind loads

or internal doors separating rooms in which pressure

differences might occur. In automatic mode, the wind load

control monitors the actual speed and will compensate for it

if the speed deviates from the set value. In combination with

the Upgrade Card Full Energy the drive unit can provide up

to 150 N at the main closing edge, which can then be used

to compensate for environmental influences.

The closing process during the last 5° can be additionally

supported by the electronic latching speed.

The door can be passed through manually. We recommend

the Push & Go function.

3.3 Low energy product

The ED 100/250 can be adjusted so that the requirements

of a low energy application (low energy drive unit) are in

accordance with the EN 16005 or DIN 18650, ANSI 156.19

and BS 7036-4. During the commissioning, the drive

parameters must be adjusted according to the specifications

of the respective standard.

The required safety of the system will be achieved with the

following characteristics:

• Reduced dynamic door panel forces/contact forces

• Low speeds

• Reduced static door panel forces/contact forces

• Force limitation

Due to system tolerances, the actual forces on the door

panel have to be measured after the teach-in run and

adjusted, if necessary, in order to comply with the local

standards and regulations.

Additional safety sensors to safeguard the rotational

movement are not required but optional if this becomes

necessary due to a risk assessment to be carried out

individually.

The safeguarding of the secondary closing edge must be

considered separately.

3.4 Control elements

The drive units ED 100 and ED 250 are electromechanical

drives. The interaction between motor gear unit and control

unit makes the automatic opening and closing possible

in the first place. The control unit must know certain

parameters of the door in order to achieve the ideal behavior.

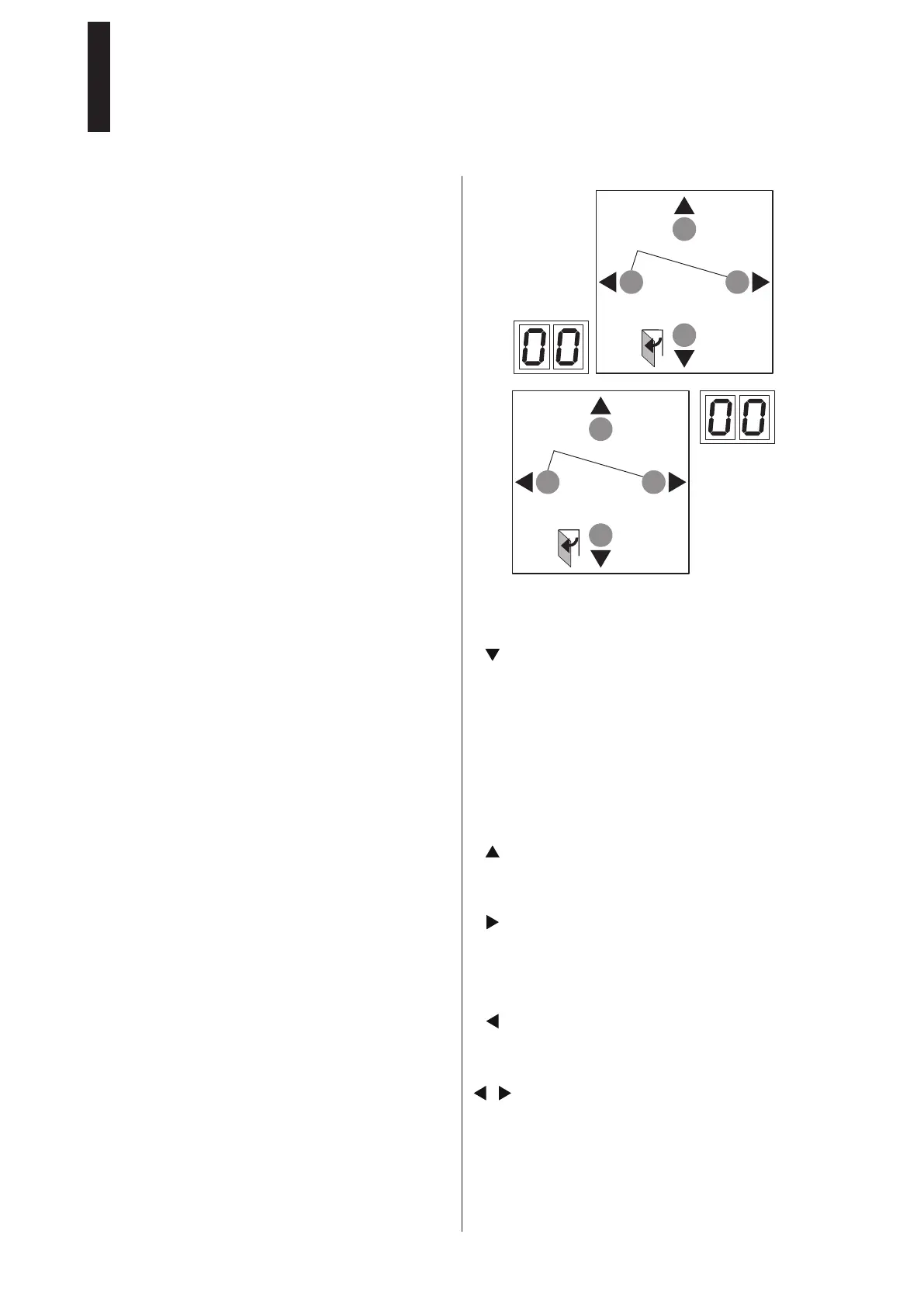

The control unit is equipped with a user interface featuring 4

pushbuttons and a 2 digit display. This allows you to make

all settings specified in the parameter list.

During the commissioning, the key functions and the display

are configured in such a way that - independent of the

installation direction of the pushbuttons - always the same

functions and the numbers and digits are shown correctly.

The legend of the pushbuttons can be removed and turned.

< 3s Quit

> 3s Reset

< 3s

> 3s

LEARN

> 8s

Fact-Setup

> 3s

PRG

DIN L

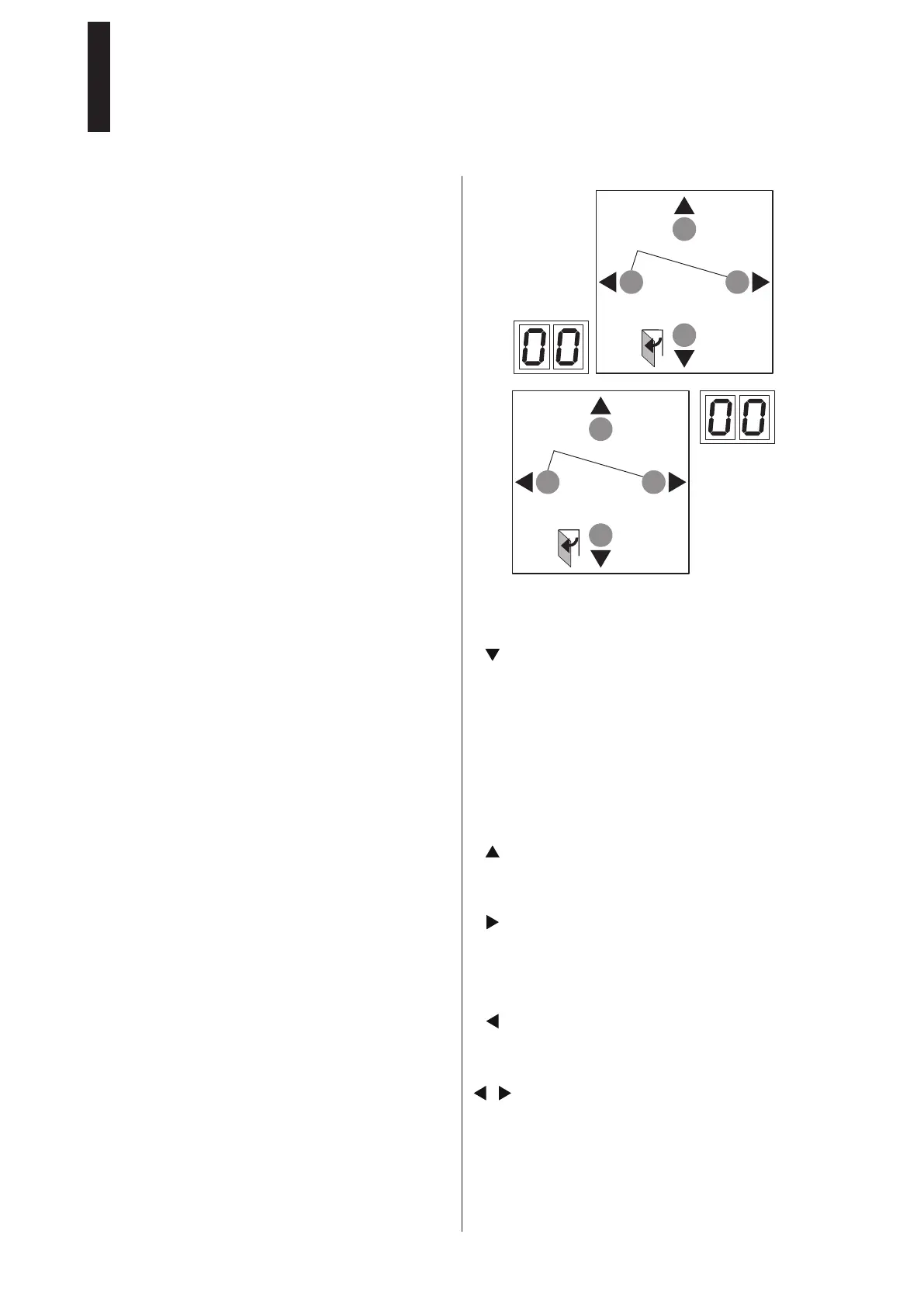

< 3s Quit

> 3s Reset

< 3s

> 3s

LEARN

> 8s

Fact-Setup

> 3s

PRG

DIN R

By pressing the pushbuttons, you can execute the following

functions:

Lower pushbutton

• Setting of the installation direction following a mains

reset

• Browsing in parameters and error messages

• Reducing the parameter value

• Opening pulse

• Teach-in run

• Reset with factory setting (Fact-Setup)

Upper pushbutton

• Browsing in parameters and error messages

• Increasing the parameter value

Right pushbutton

• Open parameter menu

• Change selected parameter

• Save changed value

Left pushbutton

• Cancel parameter change

• Exit parameter menu

Left and right pushbutton simultanuously

• Error acknowledgement

• Reset

ED 100, ED 250

—

5

Loading...

Loading...