Installing the Gas Transmitter

6

Installing the Gas Transmitter

Only trained service personnel (e.g. of Dräger) may install the gas transmitter

under observation of relevant regulations.

Installation and commissioning are described in the "Dräger PIR 3000 Installation

Instructions" which are supplied with the gas transmitter.

Mounting Location

The protecting effect of the gas transmitter depends on the selection of the

mounting location. By taking the site's air flow conditions into account, the best

possible mounting location should be chosen as close as possible to where a

decisively noticeable rise in gas concentration can be expected in case of a

leakage, i. e.

— as close as possible to the potential leakage place

— when monitoring gases and vapours which are lighter than air:

above the potential leakage place

— when monitoring gases and vapours which are heavier than air:

near to ground.

In addition, it must be assured that:

— the air circulation in the gas transmitter vicinity is not hindered

— the danger of mechanical damage is reduced as far as possible

— the gas transmitter is sufficiently accessible for maintenance purposes.

Especially the configuration via magnetic pin requires a clearance of approx.

20 cm around at least half of the sensor perimeter.

The gas transmitter can be mounted horizontally as well as vertically.

Mechanical Installation

When used according to BVS 05 ATEX E 143 X, please note:

The gas sensor type IDS 0001 (NPT) can be attached to casings with the type

of protection flameproof enclosure "d" that have a free volume of 2 litres and a

reference pressure that does not exceed 20 bar. The mechanical strength of the

attachment and the explosion and construction-related testing of the connection

thread must be carried out within the framework of the approval process of the

electrical equipment to which the sensor is attached.

The gas sensor type IDS 0011 (metric thread) is designed for attachment on a

casing with the type of protection increased safety "e". The mechanical strength

and the degree of protection IP 6X of the attachment must be ensured during

approval of the electrical equipment to which it is attached.

The junction boxes of the gas sensors IDS 00** must feature sufficient

mechanical stability to ensure that the vibrations transmitted to the sensor by the

casing are not amplified.

Terminal box

The gas transmitter is designed to be directly attached to a terminal box.

Approved connector boxes of the following makes are available as gas transmitter

accessories: Ex d (explosion proof, 3/4" NPT) and Ex e (increased safety, M25) -

(see "Order List" on page 27).

To maintain the housing protection class, the enclosed O-ring seal must be used

for an Ex e-type explosion protection connection.

Use a thread locking adhesive, e.g. Loctite

®

to prevent the M25 nut (torque of

15 Nm ±3 Nm) from self-loosening.

Use approved plugs to close any unused cable entry openings at the terminal

box.

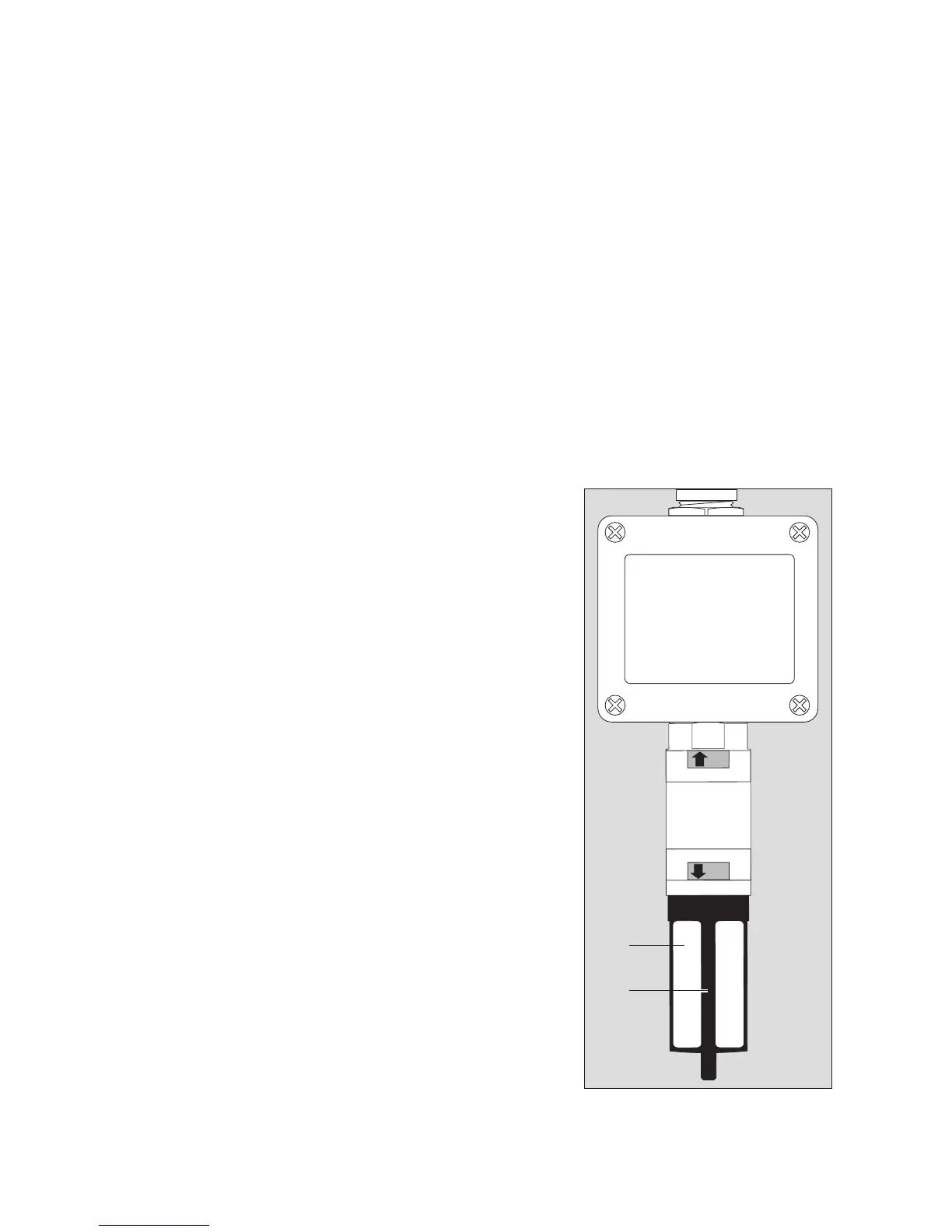

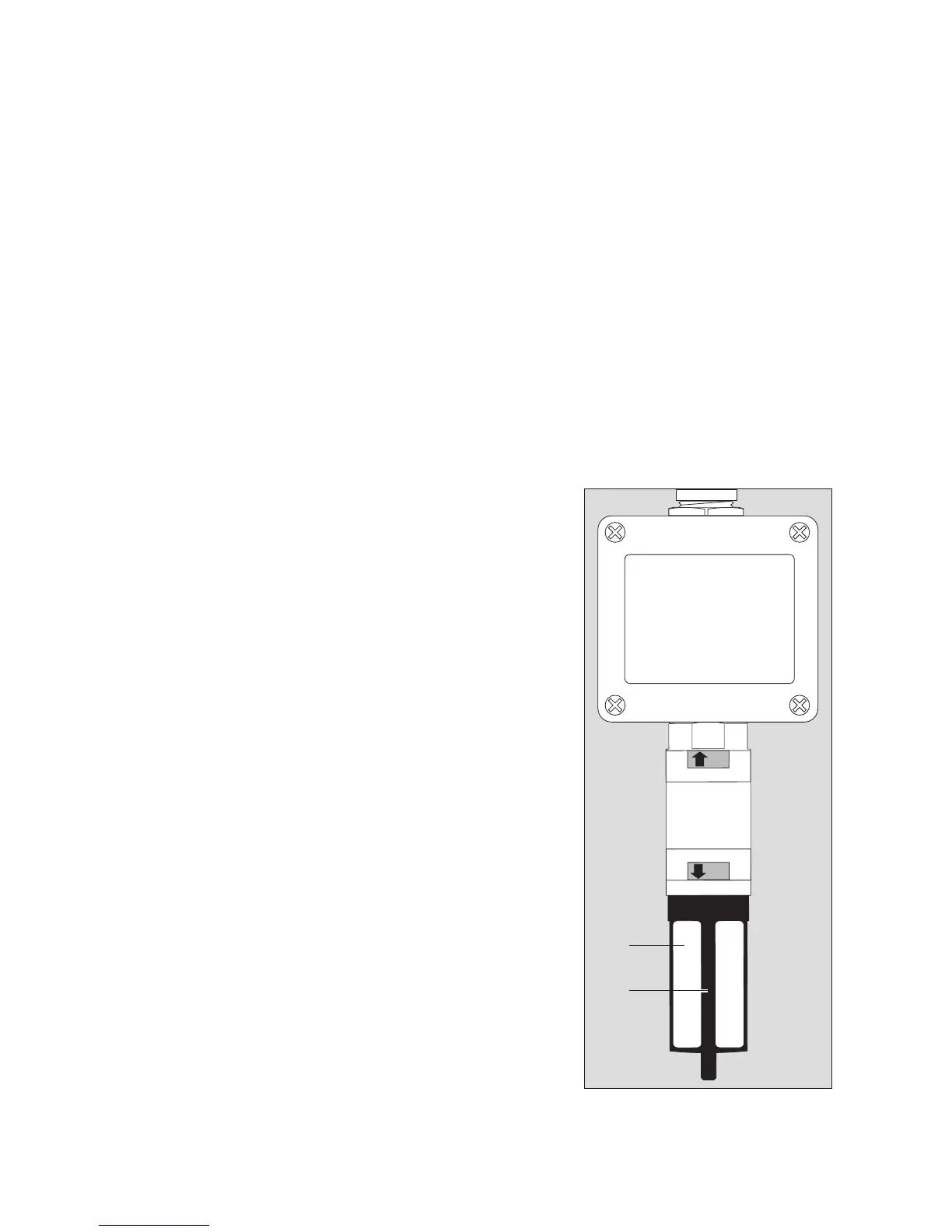

Splash Guard and Calibration Adapter

We recommend using the supplied accessories - splash guard (1) and calibration

adapter (2) - to increase protection against water jets and contamination.

0

S

00323812_02.eps

(1)

(2)

Loading...

Loading...