9

Installing the Gas Transmitter

— The leads between central device and gas transmitter must have a sufficiently

low resistance to ensure the correct supply voltage at the gas transmitter. The

maximum resistance per core is calculated as follows:

Example: With U

C

= 24 V, the result is a maximum resistance per core of R = 35 Ω.

— The maximum resistance of the loop R

I

(sum of the internal resistance of the

central device and of the cable resistance of the signal line) depends on the

transmitter supply voltage as described below:

When used according to BVS 05 ATEX E 143 X, please note:

After attachment of the sensor to a casing with the type of protection increased

safety "e", the air gaps and creepage distances must comply with the

requirements specified in 4.3 (Table 1) or 4.4 of EN 60079-7. The single core

cables must be routed and connected in a way that is mechanically protected

and complies with the temperature resistance of the wires as specified in 4.5,

4.7.2 and 4.8 of EN 60079-7.

From an electrostatic point of view (transition resistance < 10

6

ohm) the sensor

casing must be conductively connected to the equipotential bonding of the

casing to which it is attached as soon at it is attached. If equipotential bonding is

required, it must be provided with the attachment.

R = 2.5 x U

C

– 25

with R: maximum resistance per core

U

C

: voltage supplied by central device in volts (usually depends on the

supply voltage of the central device)

NOTICE

Cable resistance deviations caused by temperature influences, transition

resistances of terminals, etc. can also contribute to the fact that the calculated

cable length can not be fully used.

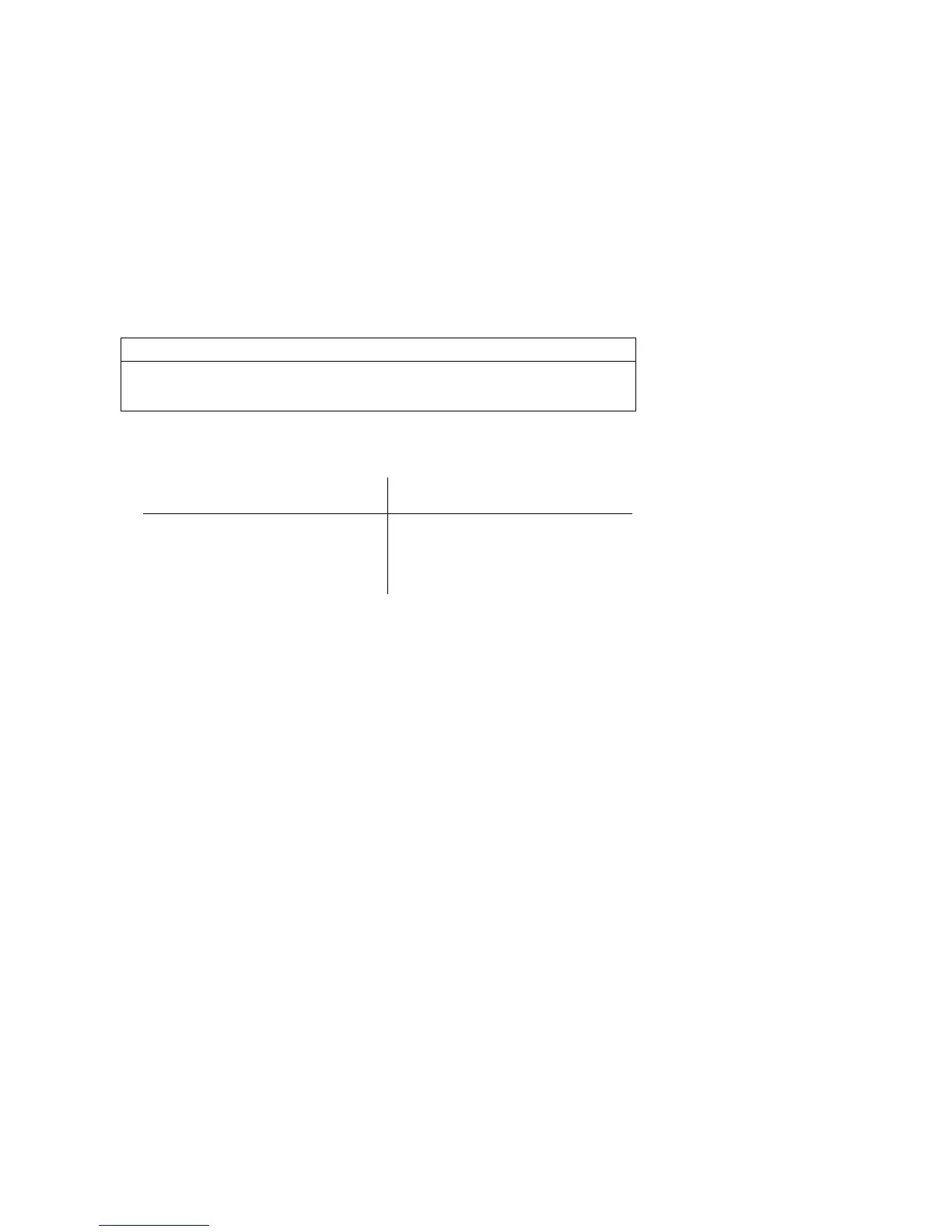

Supply voltage at

the transmitter

maximum resistance of

the loop R

I

10 V 200 Ω

12 V 300 Ω

14 V 390 Ω

16 V 480 Ω

Loading...

Loading...