5.5.2 Installation of wall-terminal and manifold

Follow the procedure below when installing the wall-

terminal and manifold:

• Drill a hole in the wall, with a diameter of 105 mm.

• Drill 3 holes in the wall from the outside, for mounting

the wall-terminal.

!Caution - Place the wall terminal with the groove/

folded seam at the top;

• Glue the sealing/gasket of the wall-terminal to the flange.

• Temporarily mount the wall-terminal from the outside.

• Slide the manifold from the inside as far as possible onto

the concentric tubes of the wall-terminal.

• Determine the distance between manifold and wall.

• Unscrew the wall-terminal.

• Cut the wall-terminal to size.

• Mount the wall-terminal for the final time.

• Determine in which angle the manifold should be placed.

• Apply a sufficient amount of heat-resistant sealant to the

outside of the galvanized steel combustion air supply tube.

• Apply a film of heat resistant sealant to the inside of the

aluminium flue gas discharge tube.

• Place the sealing/gasket of the manifold between wall and

manifold.

!Tip For the manifold, you can choose between two

combustion air supply connections.

• Mount the manifold in the correct position.

• Drill 3 holes in the wall for mounting the manifold.

• Mount the manifold with the screws and washers supplied.

• If necessary, apply a wall-terminal guard.

• Place the wall-terminal guard centrally over the wall-

terminal.

5.6 Placing the appliance

Place the appliance as follows:

Caution - Do not make any changes to the

appliance;

- Do not cover the appliance and the

discharge material and/or do not wrap

it in an insulation blanket or any other

material;

- Mount the appliance to the wall using

the wall brackets; this will guarantee the

minimum required distance of 10 mm

from the back wall;

- Make sure there is a free outflow of

warm convection air at the front of the

appliance;

- Make sure there is a free supply of

cold convection air at both sides of the

appliance. Curtains, for example, could

block the inlet as a result of the sucking

action of the convection fan.

- Avoid that warm convection air can

recirculate through the cold convection

air inlet.

!Tip - Prevent construction grid/drill material from

contaminating the appliance;

- Only mount the casing, after performing the final

check in section 7.

• Provide a gas connection at the location. For details, see

section 5.3.

• Provide an electrical connection at the location. For

details, see section 5.4.

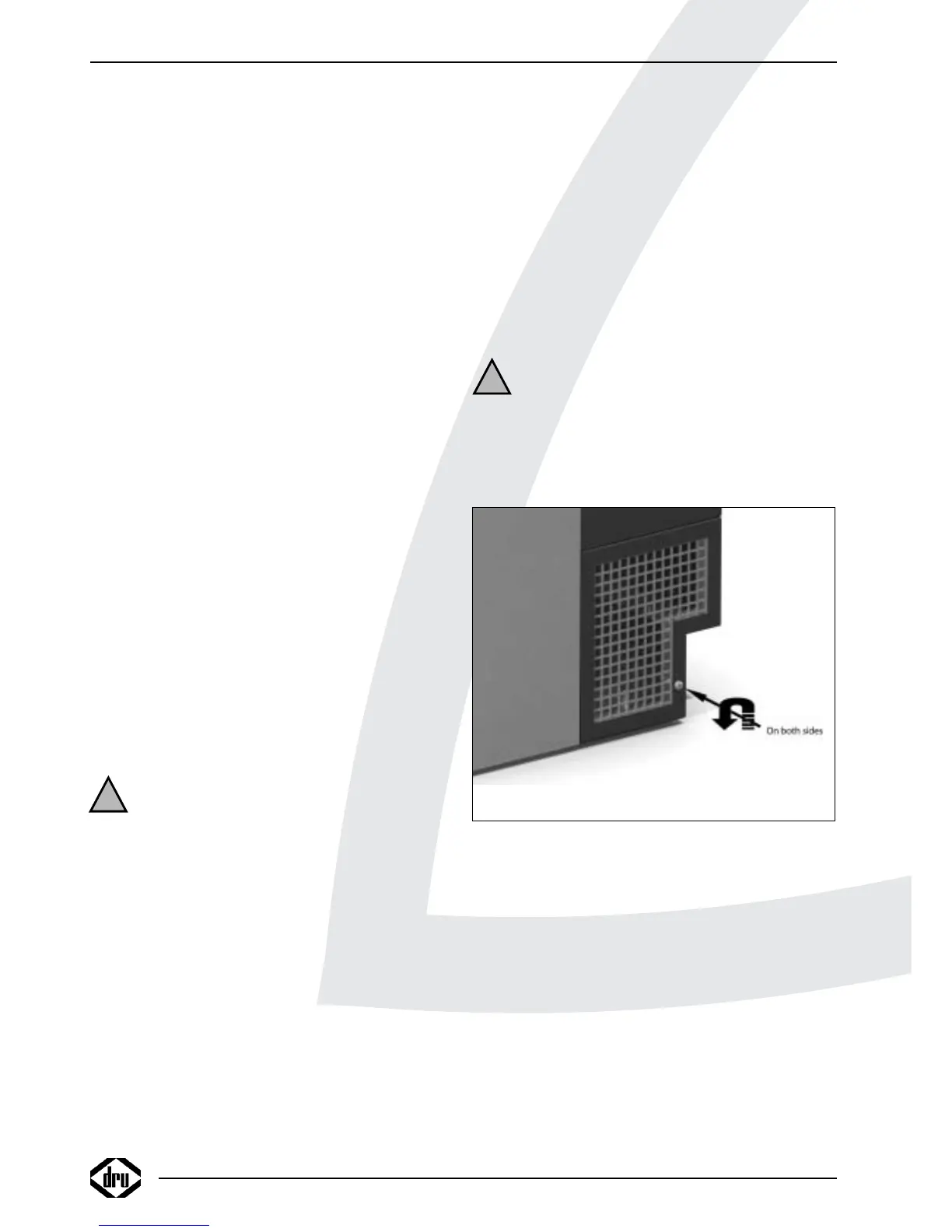

• Remove the casing:

- Unscrew the screws at both sides of the casing

(see fig. 4);

- Lift the casing appr. 1 cm and slide/lift the casing to the

front.

Caution Avoid damaging the wiring when taking off

the mantel.

• Place the appliance on its destined location.

• Drill holes for mounting the appliance.

• Attach the appliance to the wall, using the supplied plugs,

washers and screws.

5.7 Flue gas discharge / combustion air supply

system

5.7.1 Construction

For the 7kW and 12kW Power Flue, the maximum length

of the discharge tubes (vertical and horizontal) is 10

meters when using a maximum of 2 bends of 90º; when

3 bends of 90º will be used, the total maximum length of

the discharge system is 6 meters, and when 4 bends of 90º

will be used, the maximum length is 2 meters.

For the 16 kW Power Flue, the maximum length of the

discharge tubes (vertical and horizontal) is 3 meters, with

a maximum of 1 bend of 90°.

Depending on the construction, the appliance is set by

means of a restriction.

INSTRUCTIONS FOR INSTALLATION

8

!

!

Fig. 4

Loading...

Loading...