23

RFDU Operator’s ManualRFDU Operator’s Manual

23

TEMPERATURE CHECK PROCEDURE

1. A digital temperature meter that has been

calibrated must be used to get an accurate

temperature reading. Use a thermocouple

surface temperature probe to measure

temperatures.

2. No pans should be in wells during the pre-

heat and temperature check. Pre-heat the

warmer for 30 minutes before taking any

temperature readings. Do not take readings

unless the cavity has been empty for 30

minutes. This will allow the temperature to

stabilize and will prevent false readings.

3. The warmer cavity should be cleaned and

empty before the temperature is checked.

Avoid any air drafts that might ow through the

cavity.

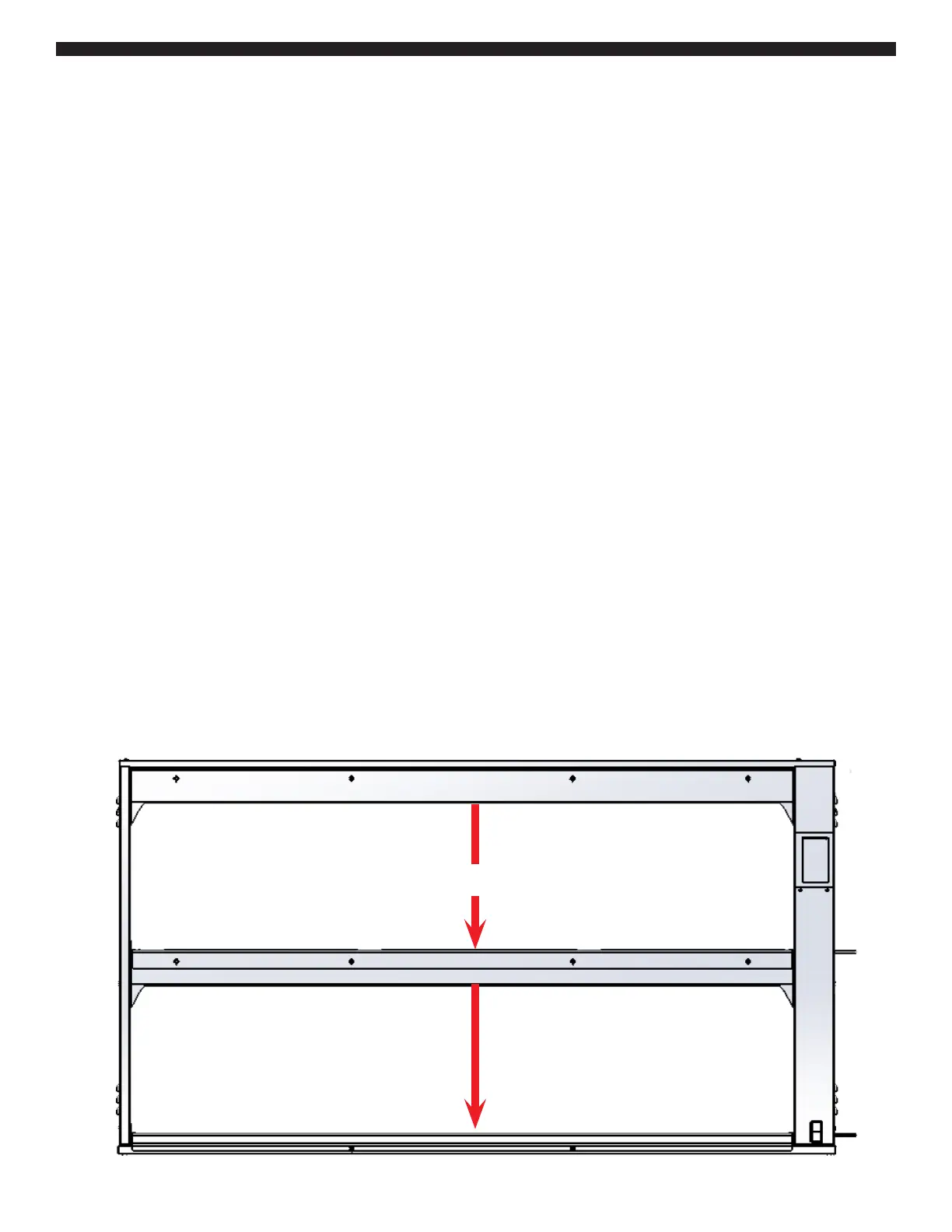

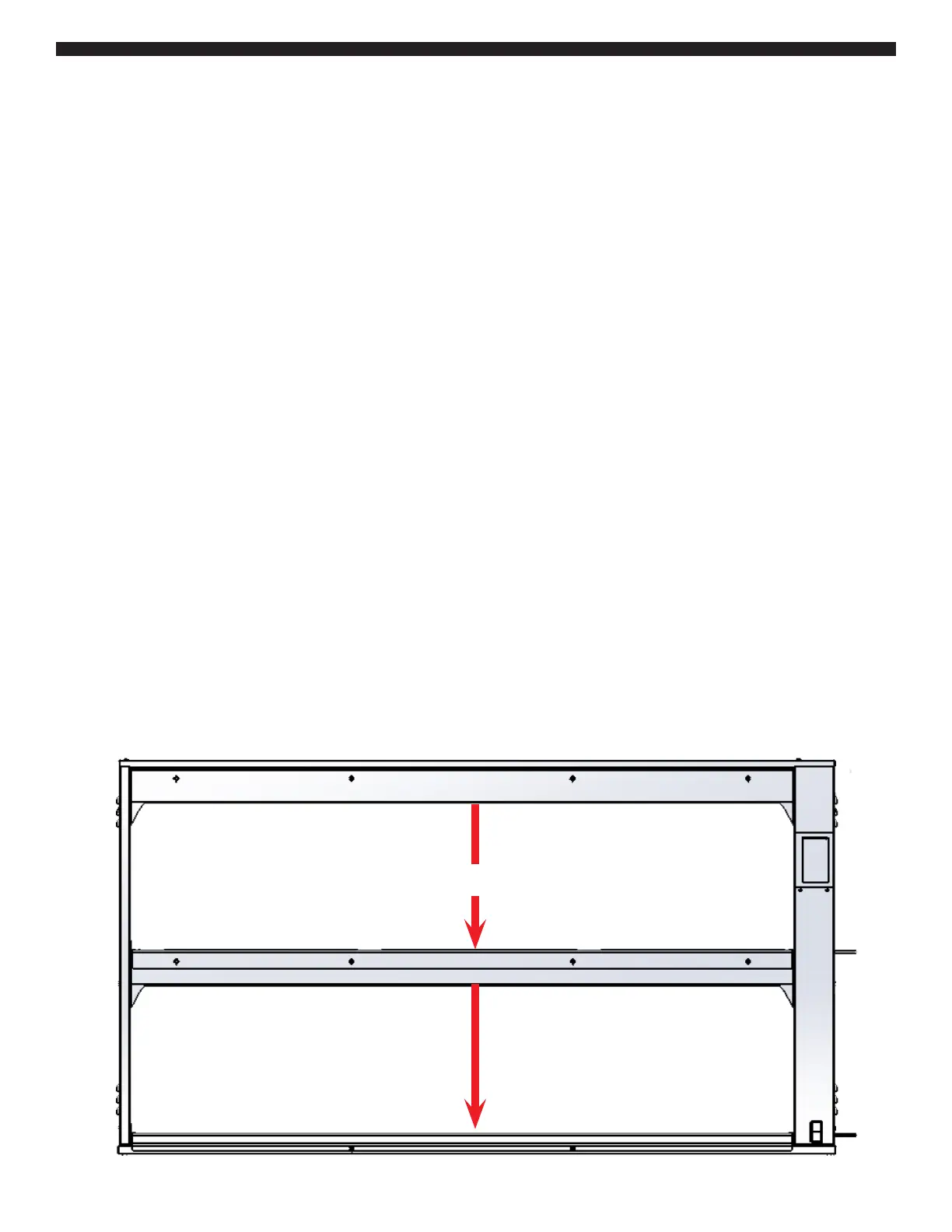

4. Temperature readings should be taken when

standing on the front side of the unit with on/

o switch. Locate the surface temperature

probe on the bottom of the rst shelf. Position

the probe half way back on the heat sink and

centered left to right as shown.

5. All temperature controls exhibit a swing in

temperature as the control cycles on and o

while regulating to the set point. The correct

calibration temperature is the average of several

readings taken over a period of 20 minutes after

the warmer has been pre-heated. The average

temperature should be no greater than ± 10°F

(± 6°C) from the set point.

6. The allowable range of well temperatures which

can be programmed on the RFDU is 140°F-280°F

(60°C-137.8°C).

7. If the calibration temperature is greater than

+/- 10F (6C) from the set point, adjust the

temperature oset as described under the Tools

menu. The oset value should be set as the

dierence between the calibration temperature

and the set point.

8. Repeat for all heat sinks.

Center Probe Front to Back

Loading...

Loading...