19

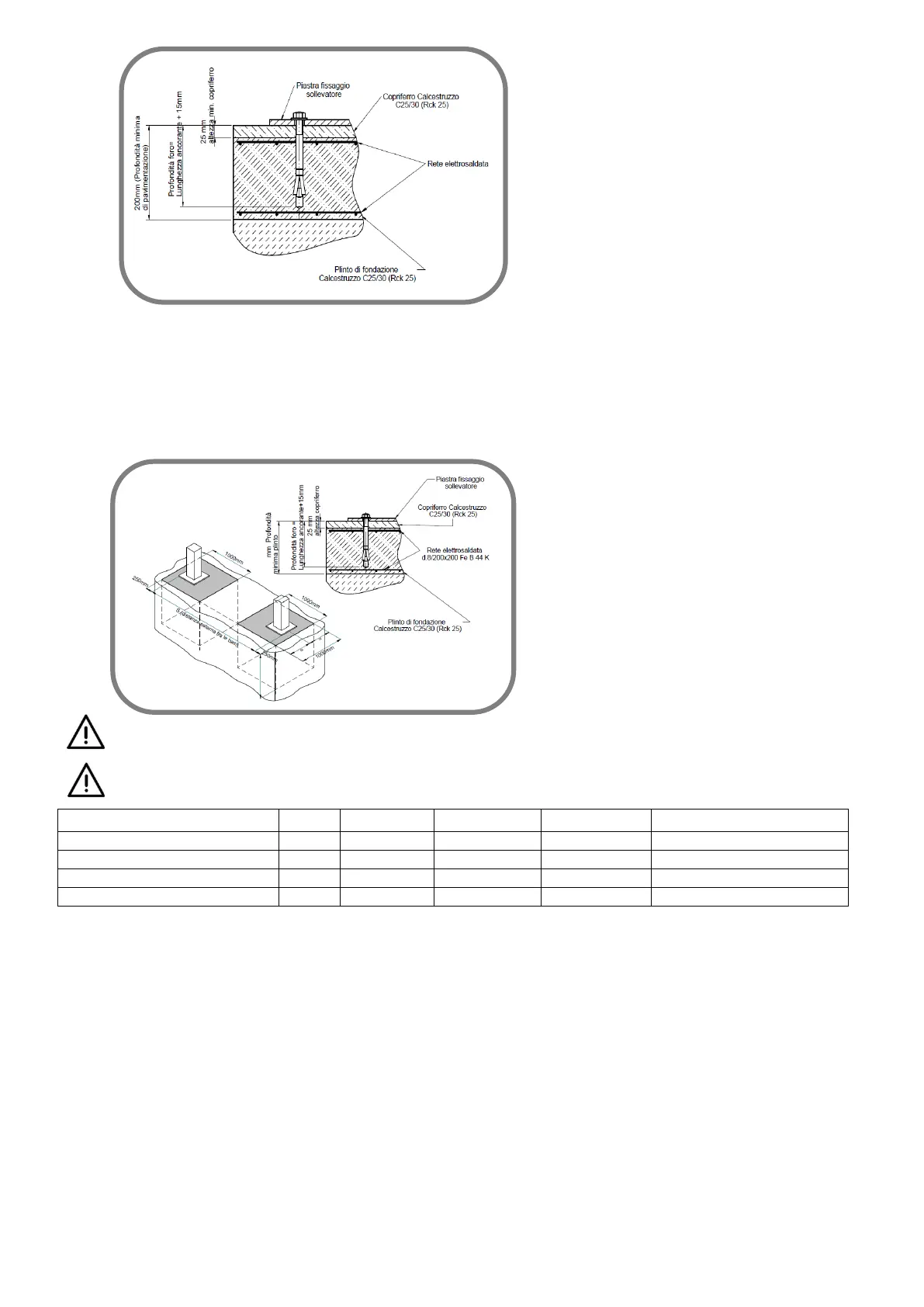

Dimensions 1000x1000 (figure 3).

Depth 600 mm.

Concrete class 32mpa.

Reinforcement Fe B 44 K.

Concrete class 32mpa.

Reinforcement Fe B 44 K.

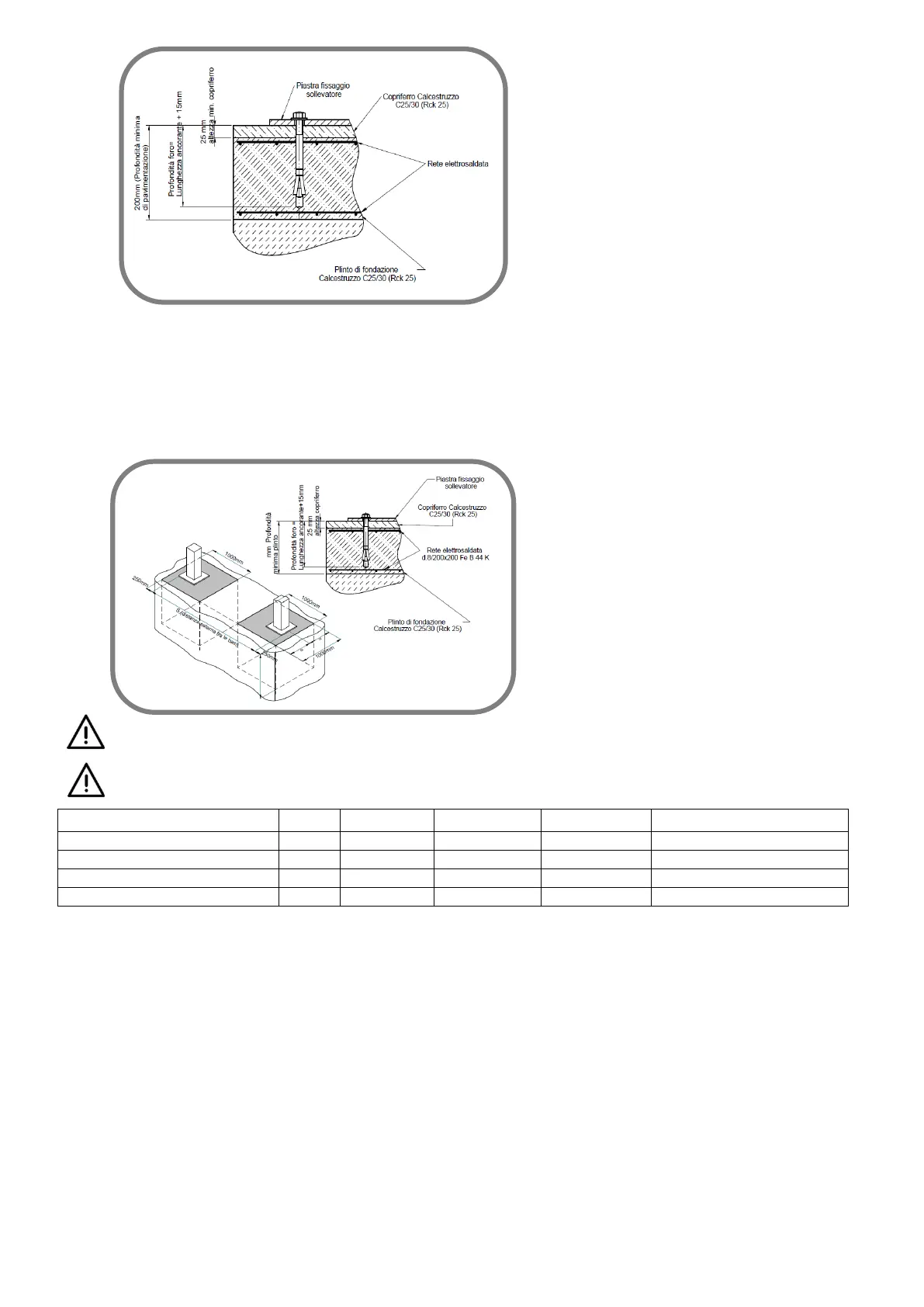

The lift must be fixed to this surface using heavy-duty anchor fixtures as described in the “Anchor Bolt Installation

Procedure” section of the manual.

The said surface must be capable of supporting at least 25 Kg/cm2 and have a strength rating of at least 32mpa.

The layer of concrete must be sufficient to ensure effective installation of the anchor bolts, and have a good

structure to a depth of at least 200 mm.

If a surface of this kind is not available, two separate foundation plinths can be constructed. The minimum

characteristics required are:

The floor must be able to withstand a load equal to the sum of the weight of the lift itself and the maximum payload, bearing

in mind the lift support surface area and anchor fixtures used.

The installation procedure foresees the use of the accessory plugs kit (optional), for equivalent models refer to the table

below and / or to the technical sheets of the product used.

Min depth for

installation

120 mm 60

4.3 INSTALLATION

After unpacking, handle the pillars with the aid of suitable slings.

Anchor bolt installation procedure:

1. Place the two pillars in the installation zone.

2. Straighten the pillars to the vertical position and then position them so that they are properly aligned with the

distance between them (fig. 3).

3. If necessary place shims underneath the bases of the pillars so that they are firmly sup-ported and the pillars

are perfectly vertical.

4. Use a drill bit ø16 to drill holes at least 100 mm deep, and clean the holes thoroughly.

5. 5.Fit the M16 Fischer FBN II16x50 or equivalent anchor bolts in the holes and then tighten with a torque wrench

set at 100 Nm: first place the thick washer provided with the fixing kit between the anchor bolt washer and the

pillar base plate.

After a few cycles with full load, check that the anchor bolts are still firmly tightened. This check must be repeated

every 3 months.

HST3-M12x105 30/10

Loading...

Loading...