31

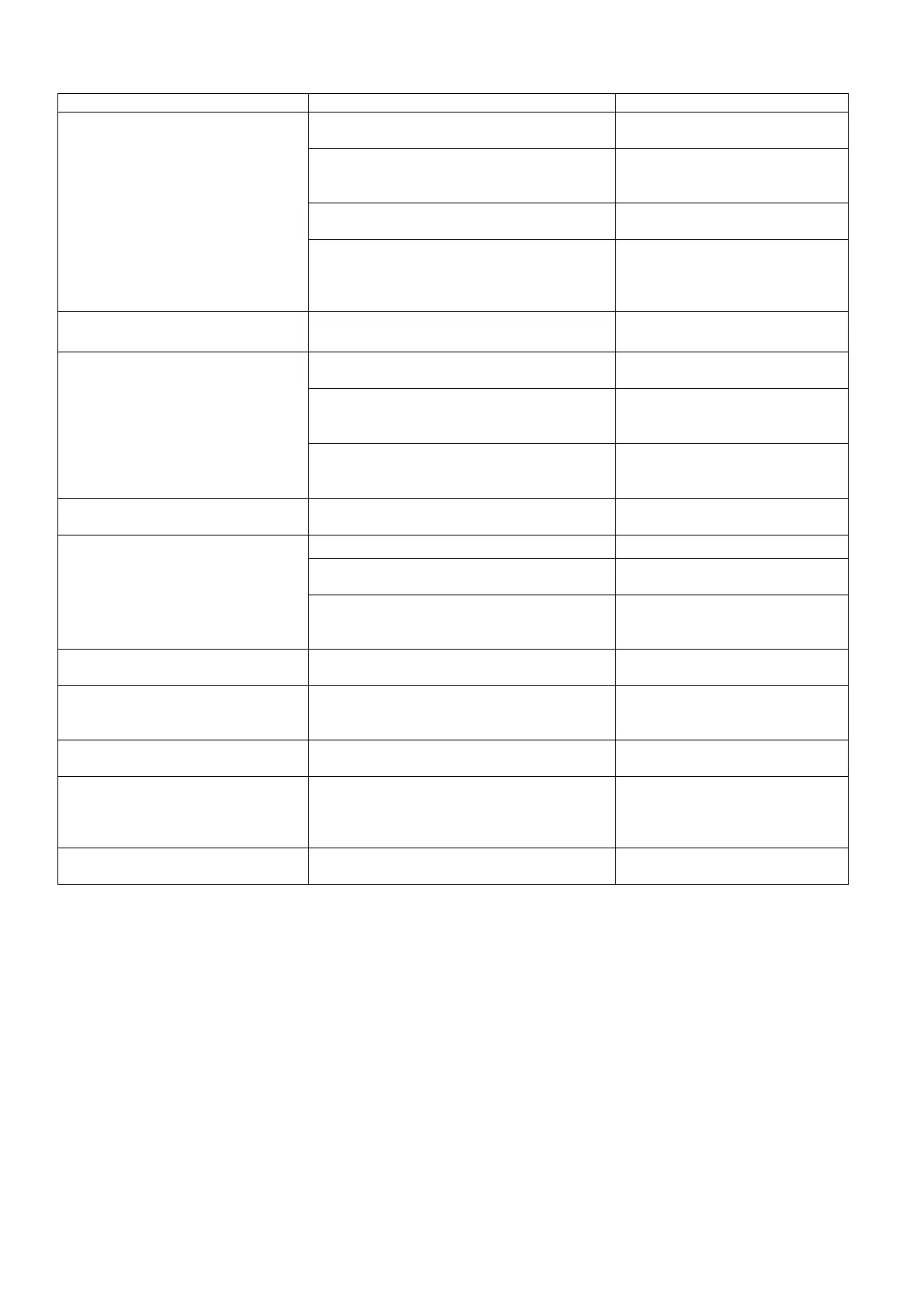

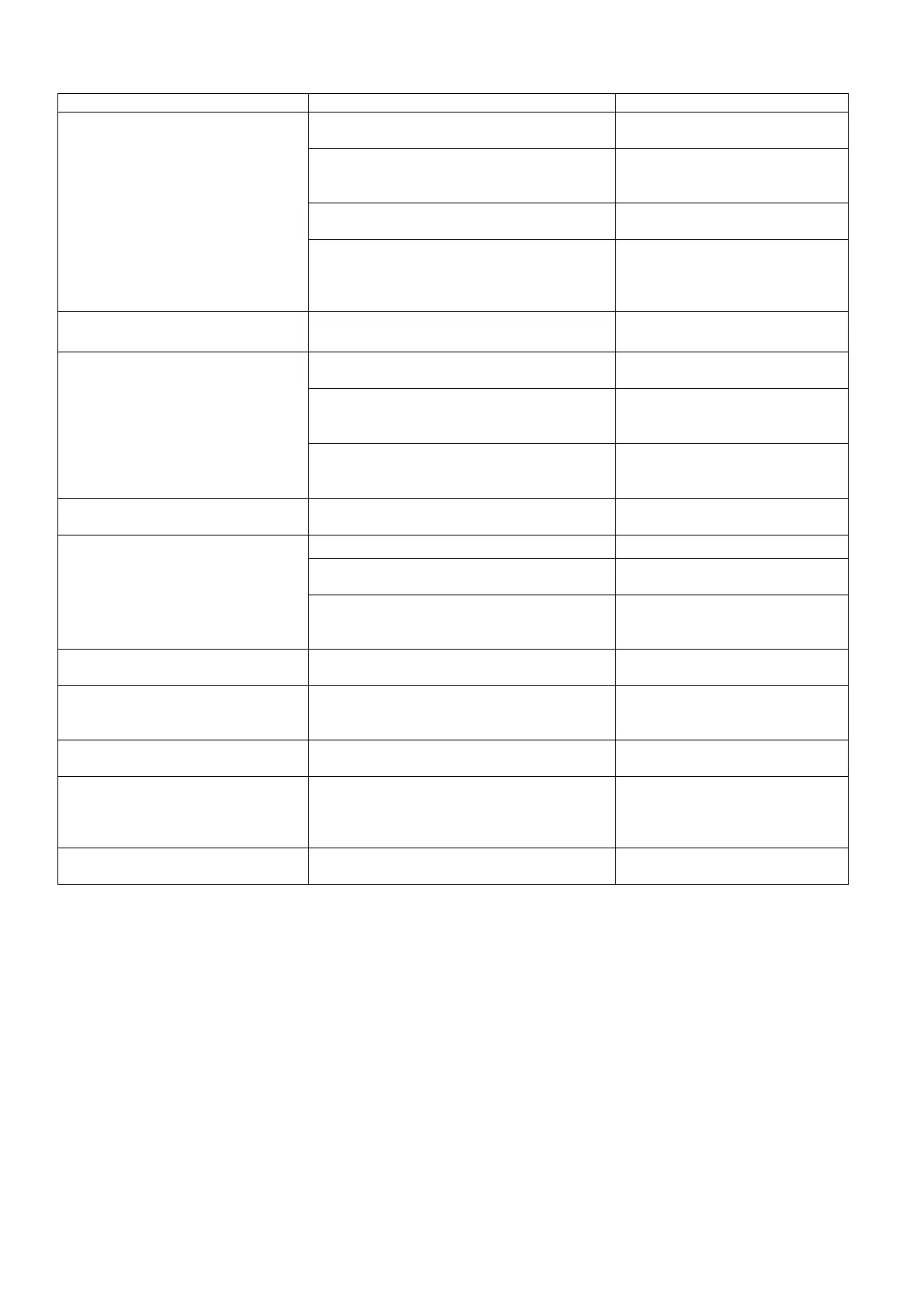

7 – TROUBLESHOOTING

Problem Cause Solution

The Lift is connected to the

mains, but does not work and

the power indicator [10] is off.

The transformer primary mains switch is

in the OFF position.

Take it to the on position.

The emergency switch QM located on the

switchboard crankcase is in the OFF

Take it to the on position.

The switch (QM) inside the electrical

panel is in the OFF position

Rearming the Switch

Power indicating lamp is off, can not do

any control; three phase equipment's

motor has abnormal noise but can not

work properly ( lack of phase power).

Check the voltage under the

fuse base if it is normal? If it is

abnormal, please replace the

No operation

Electrical system failure Contact Service

The lift does not complete the

lifting stroke

Load exceeding the maximum flow rate

Check the maximum capacity

of the lift

Supply voltage too low Check the supply voltage

Low oil level Fill the oil level

Noise during the ascent or

descent movement

Mechanical parts (chain, pulleys, sliding

pad) without lubrication

Provide for lubrication

Liftcan not completely lower

down.

Electromagnetic did not open completely

Adjust the installation position

of electromagnetic valve.

The stroke switch at the end of chain

protection device did not work.

check the wiring of the stroke

switch and wiring terminal if

Poor synchronisation of the

carriage

The levelling cables have a different

adjustment

Adjust the nut on the ropes

The lifter struggles to up and to

down

The down (YV1) valve is open or

damaged

Disconnect the down valve and

clean it. If it is damaged

proceed with the replacement

Oil leakage from connections

Loose fittings.

Tighten fittings, replace if

necessary

When the lift button is

released,the lift will

automatically descend

Explosion-proof valve clearance is too

small or closed

Remove the explosion-proof

valve and adjust the clearance

to about 1mm

Other

If you cannot resolve the

problem contact our service.

Loading...

Loading...