21CA 251/301 M251EN2

EVERY 250 HOURS OF OPERATION (Monthly)

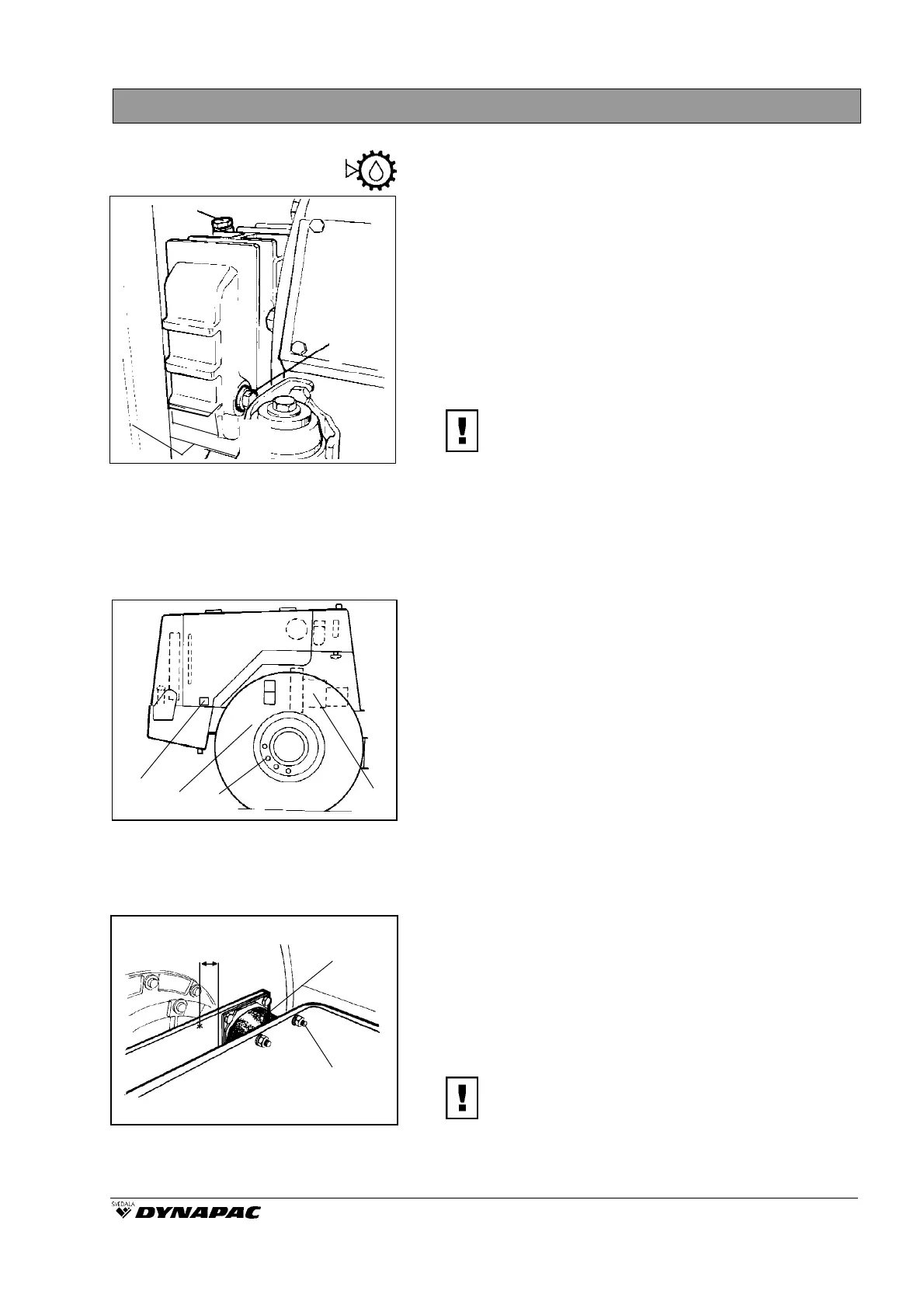

1

3

2

1. Make sure the roller is level.

2. Wipe clean around the level plug (2) and loosen it a

few turns. Oil should run out from the plug if oil

level is correct.

3. If required, top off via the filler plug (1) until oil runs

from the level plug (2). Wipe clean around the filler

plug before unscrewing it. Use transmission oil. See

Lubricant Specification.

A level plug is fitted on both sides of the

transfer gearbox. The level need only be

checked on one side.

Fig. 32 Level Control

1. Filler plug

2. Level plug

3. Drain plug

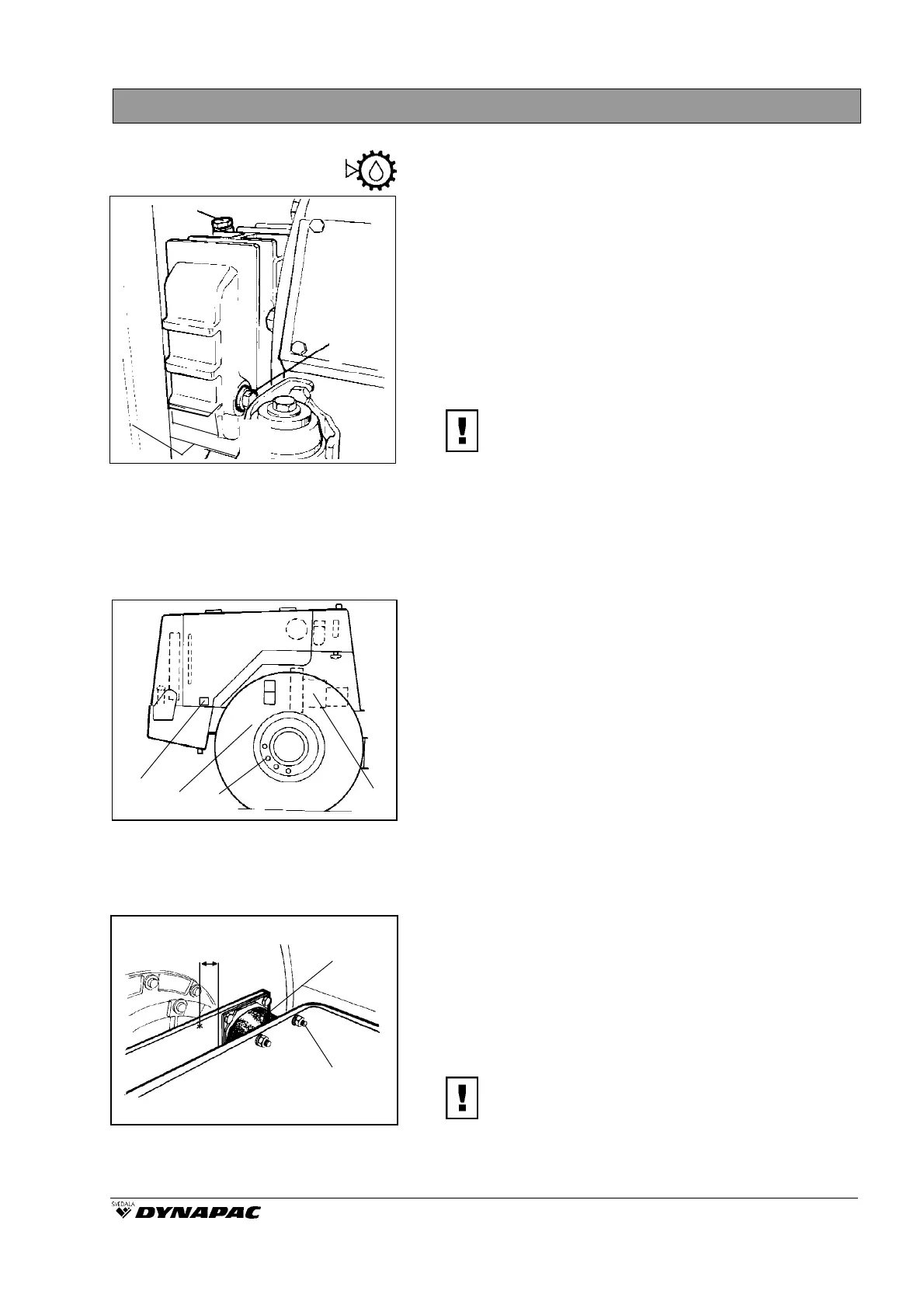

Check all the rubber elements (1), replace all the

elements if more than 25% of them on one side of the

drum are cracked deeper than 10 to 15 mm (0.4-0.6").

Use a knife, or similar tool, to check depth of cracks.

Check that the fastening bolts (2) are tightened.

Using a vernier gauge, measure the length of

the rubber element, including the mounting

plates. See separate workshop instructions if

the size is greater than 76 mm (3").

Check tightening torque of

bolted joints

28

25

20

1. Rear axle suspension (25) 434 Nm (320 ftlbs).

2. Steering pump against propulsion pump (20) 38 Nm

(28 ftlbs).

3. Engine suspension (28). Check that all bolts are

tightened, 90 Nm (66 ftlbs).

4. Wheel nuts (23). Check that all the nuts are tight,

550 Nm (406 ftlbs) tightening torque.

(The above applies only to new or replaced

components.)

23

Fig. 33 Drive unit

Fig. 34 Drum, vibration side

1. Rubber element

2. Fastening bolts

Transfer Gearbox -

Checking the Oil Level

2

1

CAUTION

CAUTION

Rubber elements and fastening

bolts - Checking

Max 76mm (3")

Loading...

Loading...