For more information visit: www.cutler-hammer.eaton.com

Page 12-3

Effective 10/02 IL17562BH04

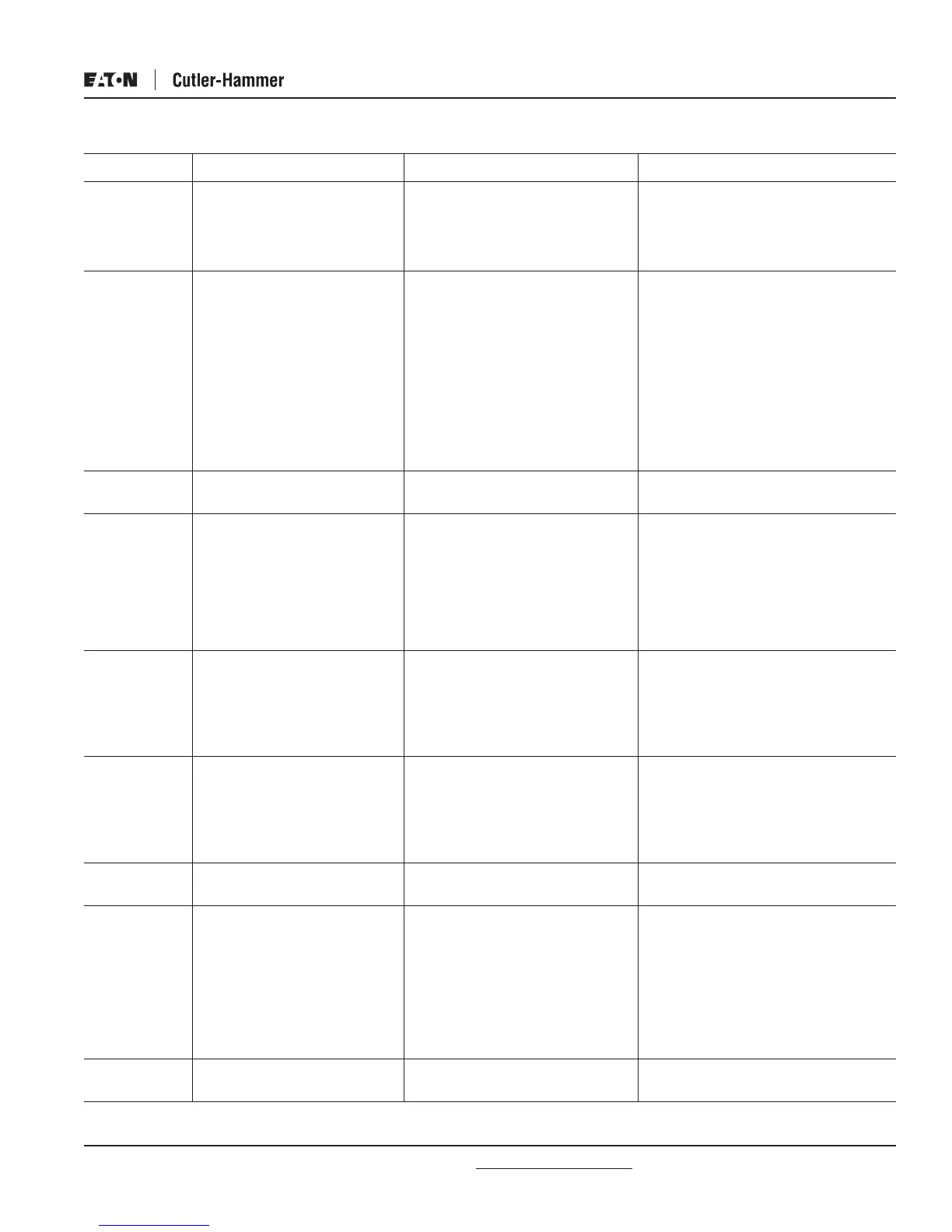

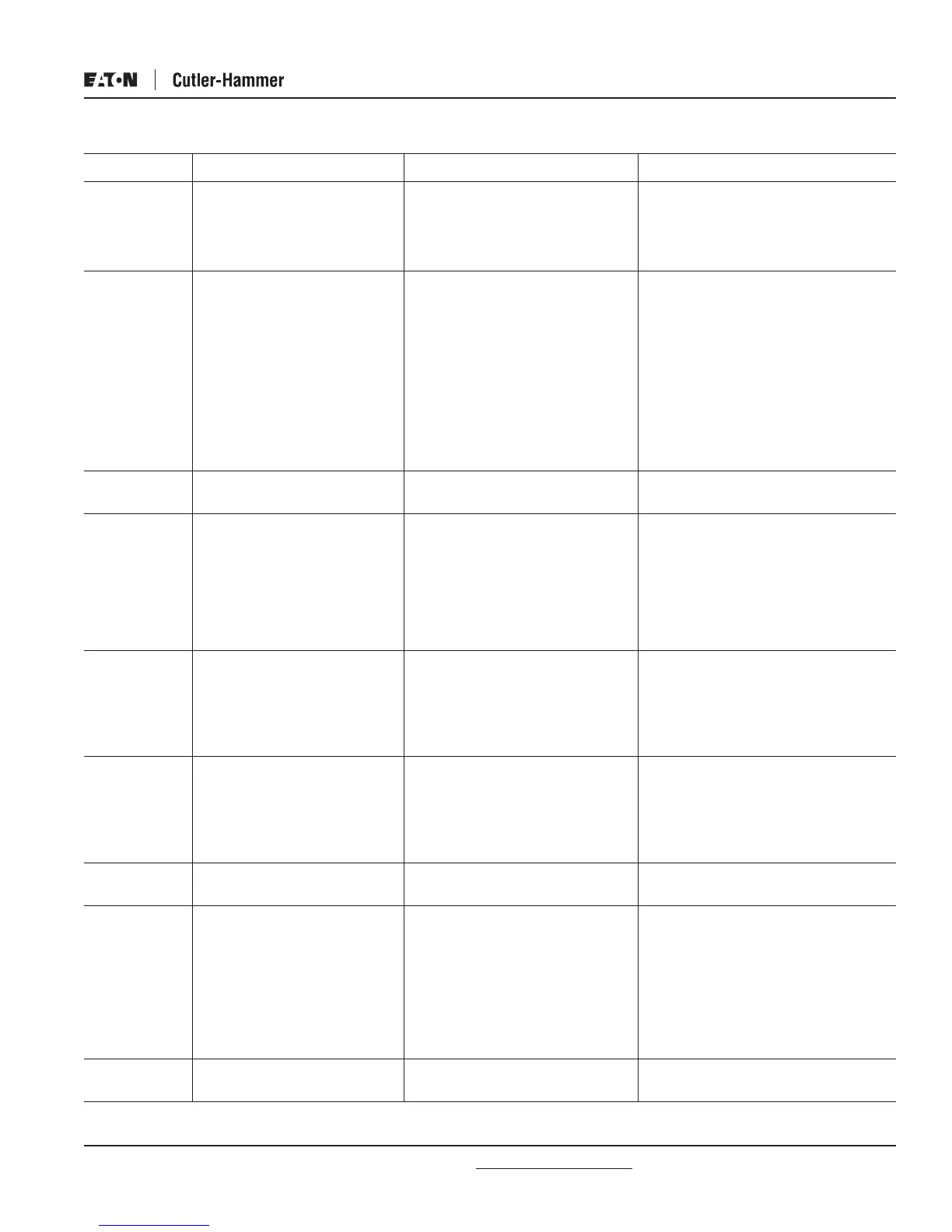

Display

GND FAULT

%I2T

STEX A

WD TEMP

MB TEMP

LB TEMP

AX TEMP

PH UNBAL

JAM

UNDER L

RTDF 3W

RTDF FIB

URTDF

RTF XX

IOC

GND FLT

JAM

Complete Help Message

GROUND FAULT ALARM

I2T ALARM

ALLOWED STARTS EXCEEDED,

WAIT IN MINUTES

STATOR WINDING TEMPERA-

TURE ALARM

MOTOR BEARING TEMPERA-

TURE ALARM

LOAD BEARING TEMPERA-

TURE ALARM

AUXILIARY OVER TEMPERA-

TURE ALARM

PHASE UNBALANCE ALARM

LOAD JAM ALARM

UNDER LOAD RUN ALARM

FAILED RTD COMMUNICA-

TION -FIB- FIBER CHAN

-3W- THREE WIRE CHAN

FAILED URTD COMMUNICA-

TION (log display only)

RTD CHANNEL FAILED ALARM

(xx = channel that failed)

INSTANTANEOUS

OVERCURRENT TRIP

GROUND FAULT TRIP

LOAD JAM TRIP

Probable Cause

Insulation failure—ground current

leakage

The thermal-model bucket level has

exceeded the alarm setting (60 to

100% of trip level).

All of the allowed count of starts in

the set time period have been used.

In each case, the temperature is

equal to or greater than the alarm

setting value.

The electrical value has crossed the

alarm threshold.

RTD temperature information

reporting through designated

medium has been lost.

A particular RTD or input to the

URTD has failed.

Electrical fault (short circuit) in

insulation of motor or connecting

circuits.

Note: If a motor trips on IOC at the

moment of starting, and an expert

has confirmed no fault, the trip may

be due to magnetic inrush. Adjust

IOC trip level and start delay to ride

through inrush peak.

Malfunction or jam of the driven

process equipment.

Solution

DANGER. Personnel hazard. Stop

and isolate motor as soon as possible

to avoid more dangerous or damaging

fault. Get expert evaluation of motor

insulation condition.

•Determine if the motor is seeing larger

than expected sustained loading.

•Check for unbalance in supply

currents or voltages causing negative-

sequence heating.

•Check for abnormal system voltage

level.

•Check for cooling air blockage or

abnormal ambient.

•Monitor the bucket level in Monitor

mode to be sure level does not

continue to rise to trip level.

Wait the number of minutes shown on

the display before restarting.

Check the problem value in the Monitor

mode and determine the cause.

Stator heat may be due to overload, or

to cooling air flow blockage.

Bearing heat usually indicates impend-

ing failure or lack of lubrication.

For unbalance, check source voltage

balance, single-phase external loads,

and uncleared unbalanced faults.

Jam and underload—look for mechani-

cal failures in driven process equip-

ment.

Check wire or fiber channel medium for

damage or disconnection.

Check URTD module for power or

malfunction.

Troubleshoot the designated RTD.

DANGER. Shut down and lock out

motor. Get expert help in evaluating

condition of motor and repair needs.

Do not try to restart without expert

evaluation.

After or during repair or replacement of

motor, check fuses in starter and

replace blown fuses.

Lock out motor starter for safety.

Check process equipment.

Table 12.1 Alarm Conditions

Loading...

Loading...