Page 12-4

Effective 10/02For more information visit: www.cutler-hammer.eaton.comIL17562BH04

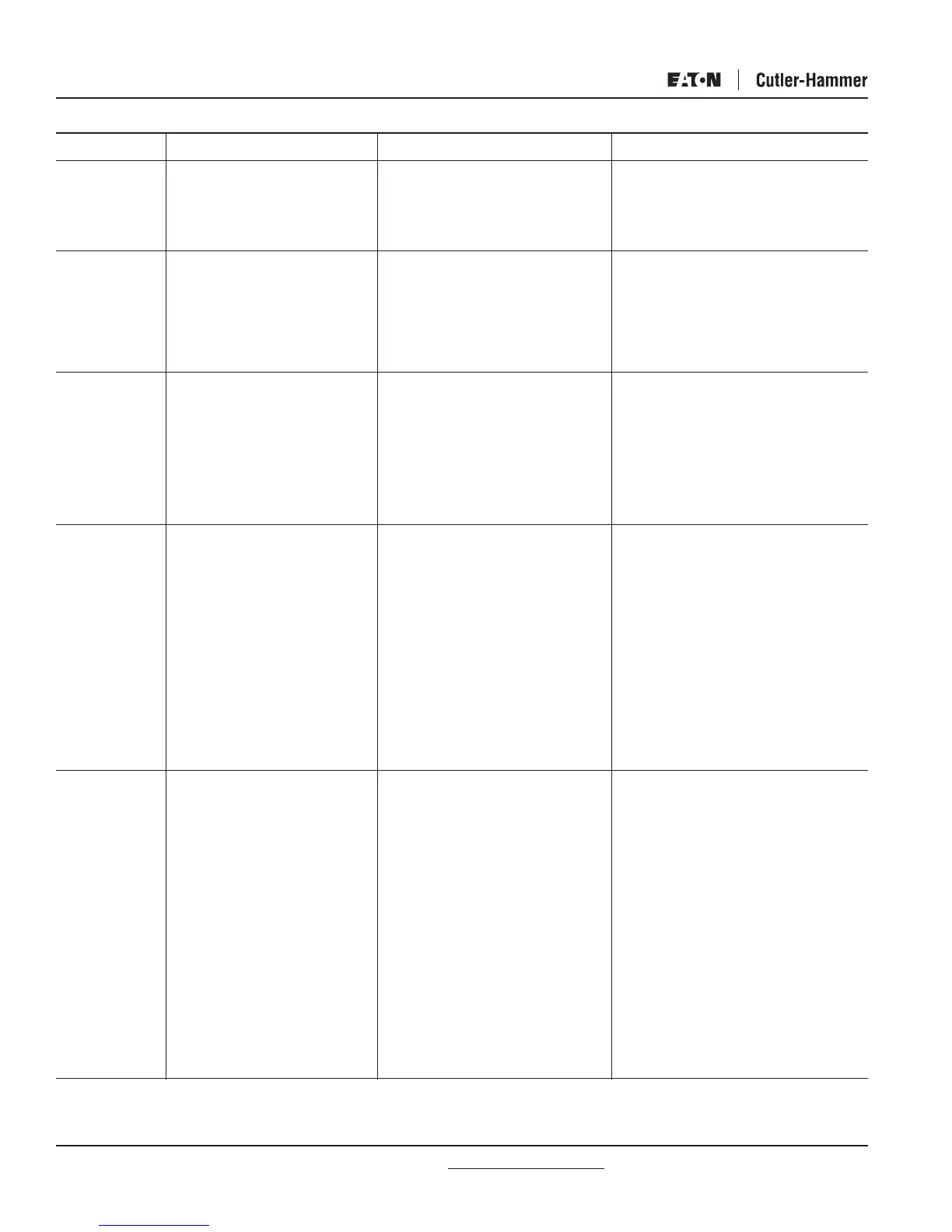

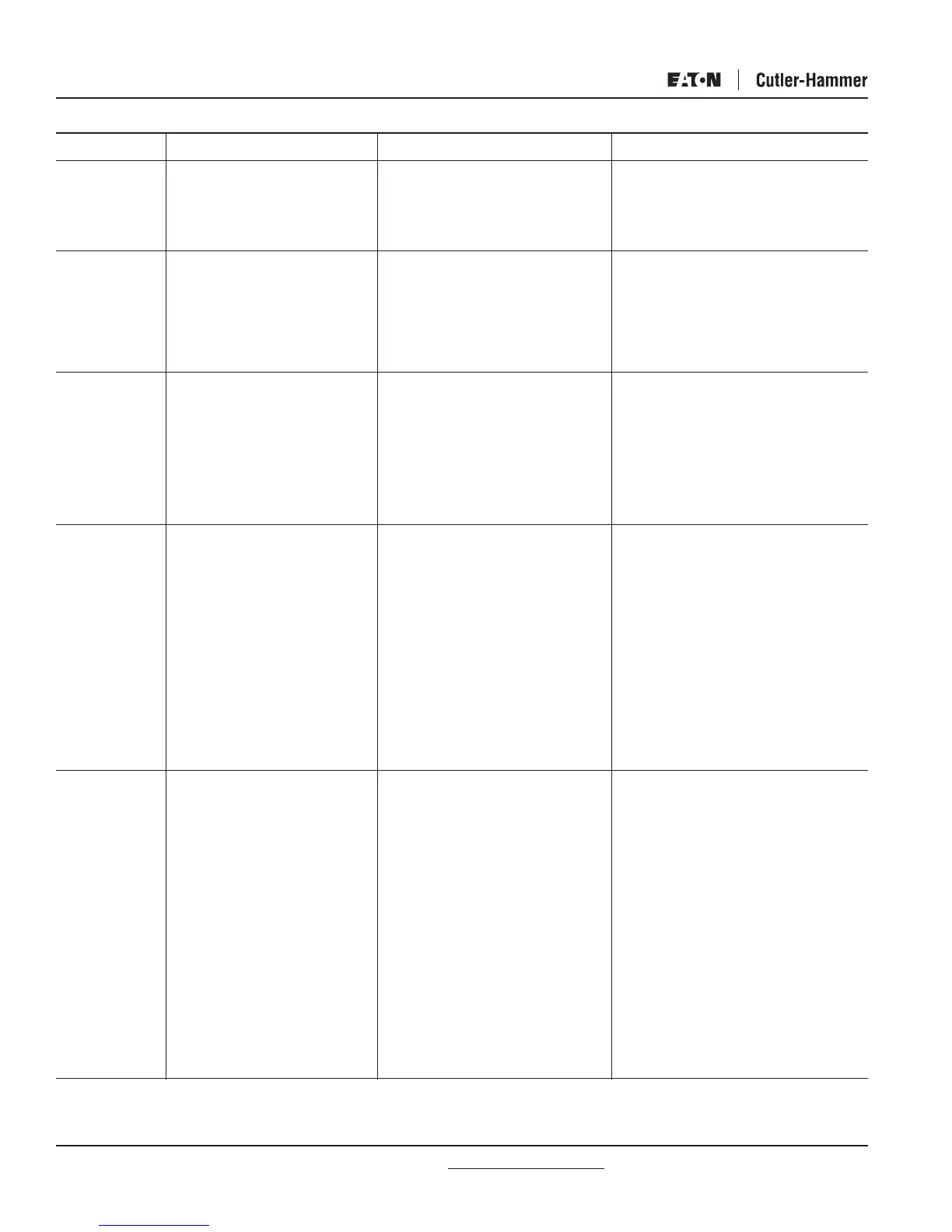

Display

UNDER L

MB TEMP

LB TEMP

WD TEMP

AX TEMP

LRC/I2T

INC SEQ

ZSW TRIP

Complete Help Message

UNDER LOAD RUN TRIP

MOTOR BEARING OVER TEMP

TRIP

LOAD BEARING OVER TEMP

TRIP

STATOR WINDING OVER TEMP

TRIP

AUXILIARY OVER TEMP TRIP

LOCKED ROTOR/THERMAL

OVERLOAD TRIP

INCOMPLETE SEQUENCE TRIP

ZERO SPEED SWITCH INPUT

FAILED TO BE FALSE WITHIN

1/2 OF LOCKED ROTOR TIME,

OR WAS FALSE AT START.

Probable Cause

Breakage or malfunction in the

process driven equipment or drive

shaft

Bearings or bearing lubrication

system has failed. Also, check RTD

integrity.

Sustained overloading of motor or

cooling air flow blockage.

The thermal-model bucket has filled

to the trip level.

Note: This trip cannot be reset until

the thermal-model bucket has

cooled (emptied) below the user-set

I2T alarm level. This time depends

on motor nameplate values entered

as settings.

Discrete input 2 has been set for

the incomplete sequence timing

function via setting P7L1. The 120

Vac feedback signal from the

process or starter, expected within

the user-set time delay, was not

received in time after the start or

transition.

Also, the discrete input 2 must

remain energized during the run

cycle, until the motor stops. An

interruption over 25 cycles will

cause an incomplete sequence trip.

Discrete input 1 has been set for

zero-speed switch sensing via

setting P6L1. The 120 Vac zero

speed switch contact input was not

present at the moment of the start;

or it did not go away in one-half of

the set locked rotor or stall time

P1L3. This may be due to a motor

which is unable to start spinning

when it is energized.

Solution

Lock out motor starter for safety.

Check shaft couplings, shaft keys for

breakage. Look for blockage of

process material flow to motor-driven

equipment.

If RTD is OK, bearing will probably

need replacement.

Check airflow path. Look for cause of

abnormal loading. Check for abnormal

supply voltage.

•Determine if the motor is seeing larger

than expected sustained loading.

•Check for unbalance in supply

currents or voltages causing negative-

sequence heating.

•Check for abnormal system voltage

level.

•Check for cooling air blockage or

abnormal ambient.

•Check to be sure this function has

been intentionally enabled.

•Check process feedback wiring to be

sure 120 Vac signal is delivered in the

expected time.

• Use DI 2 test to confirm that relay sees

input.

•Check setting P5L8 against process

feedback time.

•Check setting P5L9 to be sure correct

timing start point is selected - start or

transition.

•If timing from transition, be sure

transition current and time settings

are correct.

•Check to be sure this function has

been intentionally enabled.

•If ZSW trip occurs at the moment of

starting, check process wiring and

contact to be sure 120 Vac signal is

delivered to DI 1 when the motor is

stopped.

•Check to be sure the motor isn’t

stalled and actually begins to spin.

• If ZSW trip occurs after 1/2 the locked

rotor time setting, check to be sure

the contact on the motor opens and

the 120 Vac signal goes away before

this time. Usually, a zero-speed

switch should open when the motor

has reached 5% to 10% of its normal

running speed.

• Use DI 1 test to confirm that the relay

sees the expected input voltage.

Loading...

Loading...