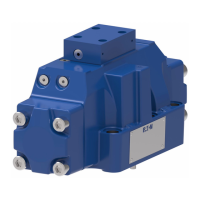

1EATON Vickers Solenoid Operated Directional Valves Product Catalog V-VLDI-MC011-E September 2008

Introduction

These solenoid operated

directional control valves are

for directing and stopping

flow at any point in a hydrau-

lic system. This 60-design

series has been specially

designed and developed to

cover expanded demands in

the industry as well as the

many traditional uses of the

earlier designs. Some of the

more important benefits to

users are outlined.

• Efcient control of greater

hydraulic powers without

increasing solenoid power

consumption.

• Installed cost and space

savings from higher

power/weight-and-size

ratios.

• Increases system efciency;

the result of improved

manufacture of spools

and bores.

General description

• Installation exibility

resulting from choice of

numerous combinations

of solenoid connectors

and locations.

• Multi-uid capability with-

out need to change seals.

• Higher sustained machine

productivity and higher

uptime because of proven

fatigue life and endurance,

tested over 20 million

cycles.

• Solenoid coils can be

changed quickly and

easily without leakage

from hydraulic system.

• Compact, cost effective

system design when used

with Vickers

®

SystemStak™

valves and subplates.

DG4V-3 and DG4V-3S

High and standard

performance models:

• Up to 80 l/min (21 USgpm)

and up to 40 l/min (10.5

USgpm) respectively at

350 bar (5000 psi).

• Builds on Eaton's experi-

ence as the major supplier

of size 03 valves world-

wide.

• Offers designers the

opportunity to select the

optimum value package

for each application.

• International standard

interface. The valve

mounting face conforms

to ISO 4401, size 03 and

is compatible with related

international standards.

Features and Benefits

• High pressure and ow

capabilities, thanks to

special design features

Highly reliable operation up

to 80 l/min (21 USgpm) at

350 bar (5000 psi). Estab-

lishes new market standards

and opens new possibilities

to design engineers on valve

size selection.

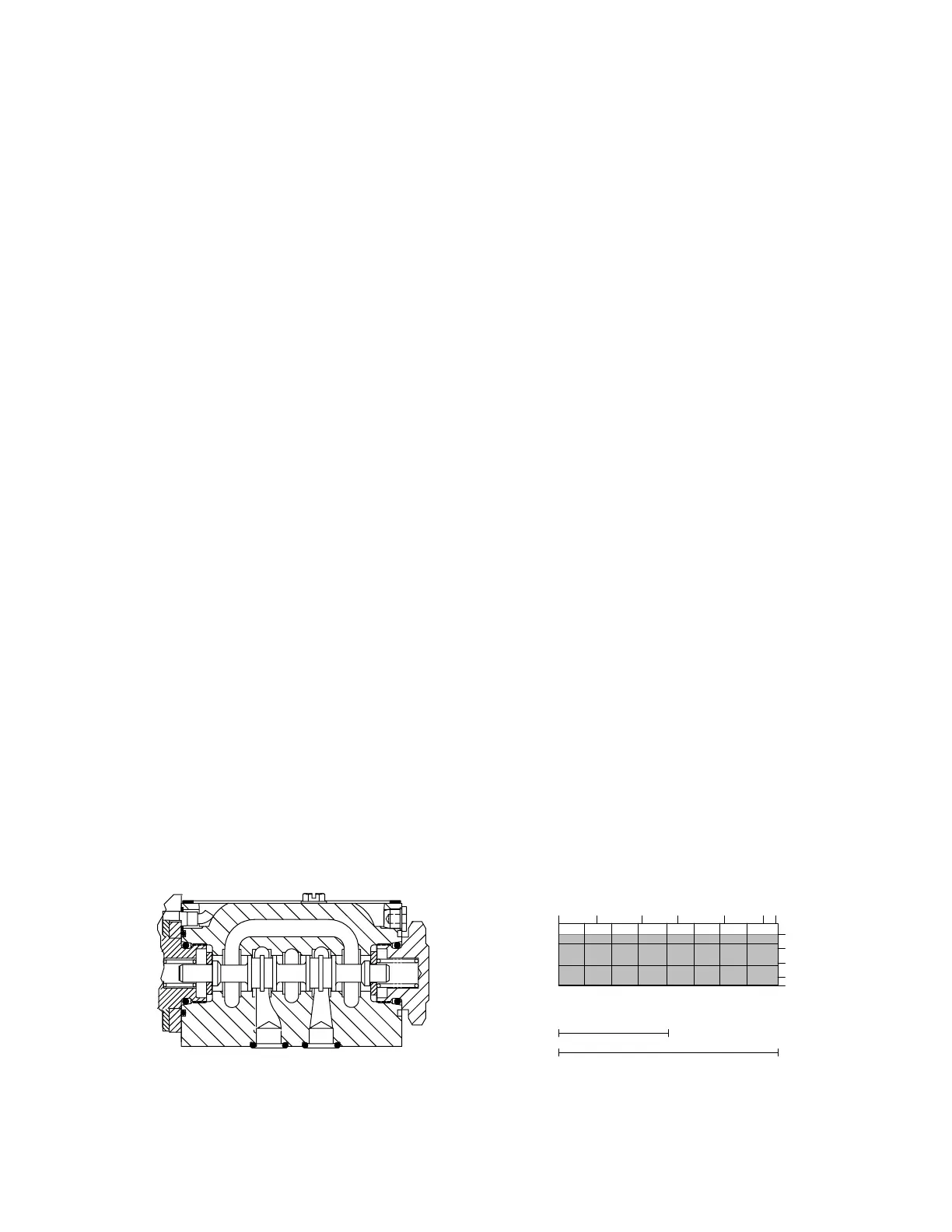

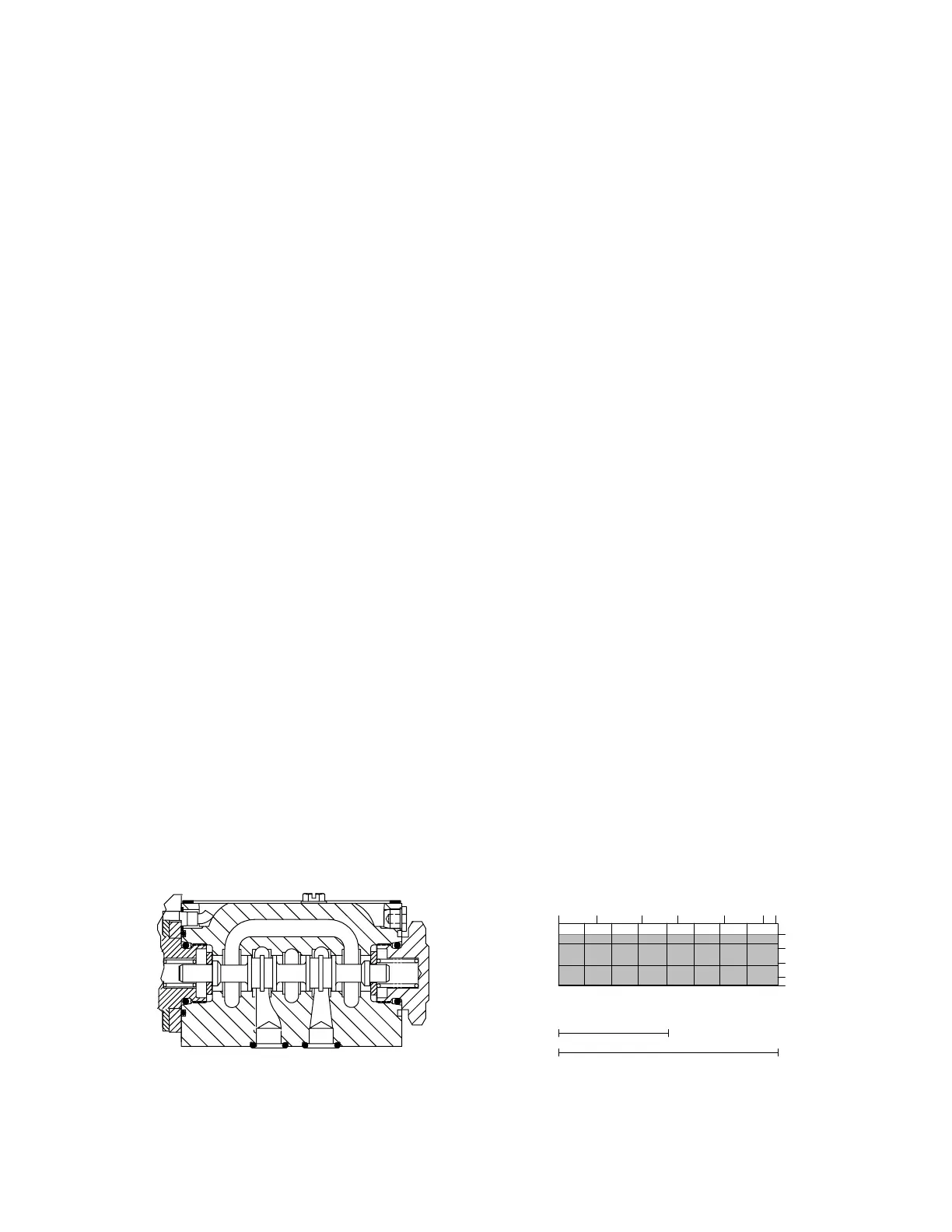

Typical maximum pressure

differential (P-A-B-T) flow en-

velope, blocked center spool.

10 20 30 40 50 60 70 80

100

200

300

400

1450

2000

3000

4000

5000

0 4 8 12 16 20 21

DG4V-3S

DG4V-3

Flow rate (l/min)

Flow rate (USgpm)

Pressure differential (bar)

Pressure differential (psi)

10 20 30 40 50 60 70 80

100

200

300

400

1450

2000

3000

4000

5000

0 4 8 12 16 20 21

DG4V-3S

DG4V-3

Flow rate (l/min)

Flow rate (USgpm)

Pressure differential (bar)

Pressure differential (psi)

Loading...

Loading...