EBARA Pumps Americas Corporation

www.pumpsebara.com

9

rev. 01/19

8.2.3 FASTENING DOWN

Bolt the pump on to a concrete base or suitable metal structure.

Use of anti-vibration supports is highly recommended in com-

mercial buildings (with occupants) if the concrete base is an in-

tegral part of the reinforced concrete structure of buildings.

When fastening, use a drill bit to center mark the 4 holes in the

base of the pump on the surface it is due to be installed on.

Use a drill to make 4 holes (dia. 12mm (15/32") for EVMSU 1, 3,

5, 10, 15, 20 pumps and dia. 14mm (9/16") for EVMU 32, 45, 64

pumps). Move the pump back into position, line it up with the

pipes and tighten the screws all the way.

The position of the fastening holes is also illustrated in section 15.6.

8.2.4 PIPEWORK

In addition to the instructions given below, also comply with the

general instructions found in sect. 15.7 of the manual and with

the directions in fig. 1.

Suction and discharge piping must be sized to

withstand the maximum working pressure of the

pump.

WARNING!

It is recommended that a pressure gauge be installed on the

discharge line before the check valve and isolating valve. Use

adequate supports for the suction and discharge lines to avoid

stress on the pump flange. If the pump is installed with a suc-

tion lift arrangement (liquid level lower than the pump) and it

feeds an open circuit, install a foot valve at the end of the suc-

tion line and use a hose connected to the pump.

Ensure that available NPSH is greater than NPSH

required by the pump. Insufficient NPSH will

result in cavitation, which reduces pump

performance and may result in damage to the

pump. Refer to the pump curves.

8.2.5 ELECTRICAL CONNECTION

Electrical connections must be made by qualified

personnel. Motor and circuit protection must be

appropriately sized. Observe all applicable codes

and standards.

Connect the electrical supply to the pump, following the motor

manufacturer’s instructions.

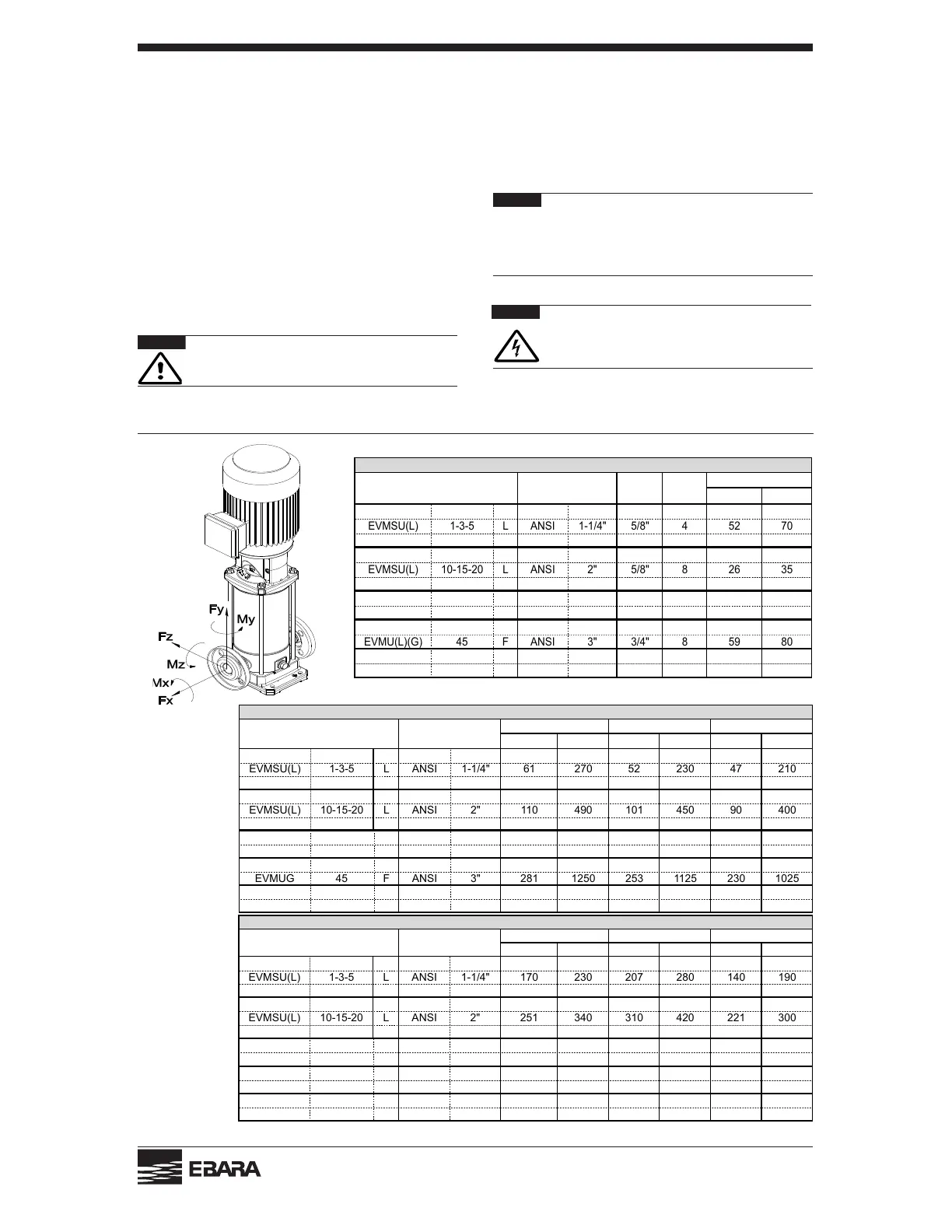

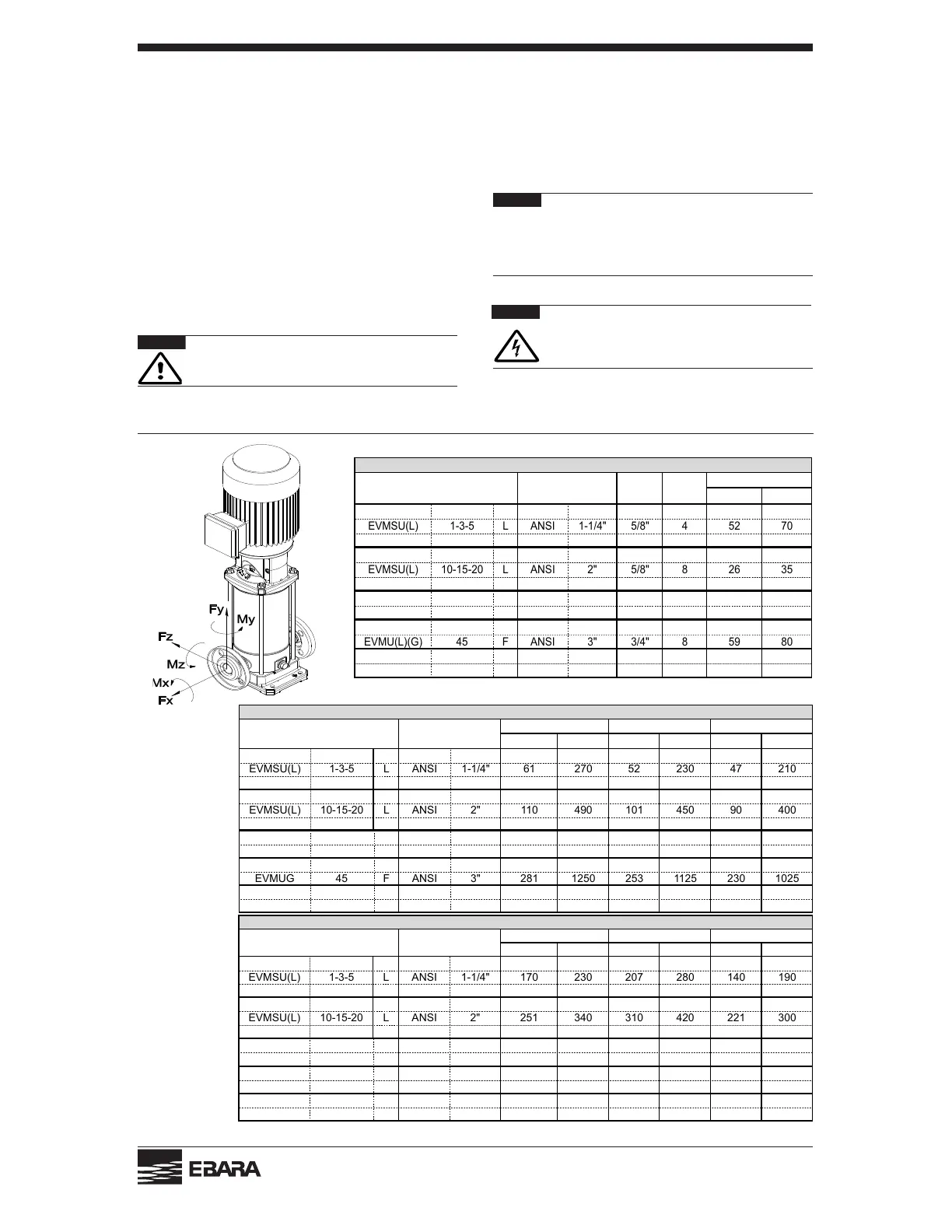

8.3 FLANGE LOADING AND TIGHTENING TORQUES

WARNING!

[lb-ft] [Nm]

EVMSU(L) 1-3-5 F ANSI 1-1/4" 5/8" 4 52 70

EVMSU(L) 1-3-5 L ANSI 1-1/4" 5/8" 4 52 70

EVMSU(L) 1-3-5 N - 1-1/4" M10 2 22 30

EVMSU(L) 10-15-20 F ANSI 2" 5/8" 8 26 35

EVMSU(L) 10-15-20 L ANSI 2" 5/8" 8 26 35

EVMSU(L) 10-15-20 N - 2" M12 2 37 50

EVMU(L)(G)

32

F ANSI 2-1/2" 5/8"

45980

EVMU(L)(G) 32 F ANSI 2-1/2" 3/4" 8 59 80

EVMU(L)(G) 45 F ANSI 3" 5/8" 4 59 80

EVMU(L)(G) 45 F ANSI 3" 3/4" 8 59 80

EVMU(L)(G) 64 F ANSI 4" 5/8" 8 59 80

EVMU(L)(G) 64 F ANSI 4" 3/4" 8 74 100

FLANGE TIGHTENING TORQUE

No. of

Bolts

Models Flange Bolt Size

Tightening torque

[lb] [N] [lb] [N] [lb] [N]

EVMSU(L) 1-3-5 F ANSI 1-1/4" 61 270 52 230 47 210

EVMSU(L) 1-3-5 L ANSI 1-1/4" 61 270 52 230 47 210

EVMSU(L) 1-3-5 N - 1-1/4" 61 270 52 230 47 210

EVMSU(L) 10-15-20 F ANSI 2" 110 490 101 450 90 400

EVMSU(L) 10-15-20 L ANSI 2" 110 490 101 450 90 400

EVMSU(L) 10-15-20 N - 2" 110 490 101 450 90 400

EVMU(L)

32

F ANSI 2-1/2" 472 2100 416 1850 382 1700

EVMUG 32 F ANSI 2-1/2" 236 1050 208 925 191 850

EVMU(L) 45 F ANSI 3" 562 2500 506 2250 461 2050

EVMUG 45 F ANSI 3" 281 1250 253 1125 230 1025

EVMU(L) 64 F ANSI 4" 753 3350 674 3000 607 2700

EVMUG 64 F ANSI 4" 377 1675 337 1500 303 1350

Strain Y [lb] Strain Z [lb]

ALLOWABLE STRAIN ON THE FLANGE

Models

Strain X

Flange

WARNING!

[lb-ft] [Nm] [lb-ft] [Nm] [lb-ft] [Nm]

EVMSU(L) 1-3-5 F ANSI 1-1/4" 170 230 207 280 140 190

EVMSU(L) 1-3-5 L ANSI 1-1/4" 170 230 207 280 140 190

EVMSU(L) 1-3-5 N - 1-1/4" 170 230 207 280 140 190

EVMSU(L) 10-15-20 F ANSI 2" 251 340 310 420 221 300

EVMSU(L) 10-15-20 L ANSI 2" 251 340 310 420 221 300

EVMSU(L) 10-15-20 N - 2" 251 340 310 420 221 300

EVMU(L)

32

F ANSI 2-1/2" 885 1200 1106 1500 811 1100

EVMUG 32 F ANSI 2-1/2" 442 600 553 750 406 550

EVMU(L) 45 F ANSI 3" 959 1300 1180 1600 848 1150

EVMUG 45 F ANSI 3" 479 650 590 800 424 575

EVMU(L) 64 F ANSI 4" 1069 1450 1291 1750 922 1250

EVMUG 64 F ANSI 4" 535 725 645 875 461 625

ALLOWABLE TORQUE ON THE FLANGE

Models Flange

Torque X Torque Y Torque Z

Loading...

Loading...