20

Maintenance and care

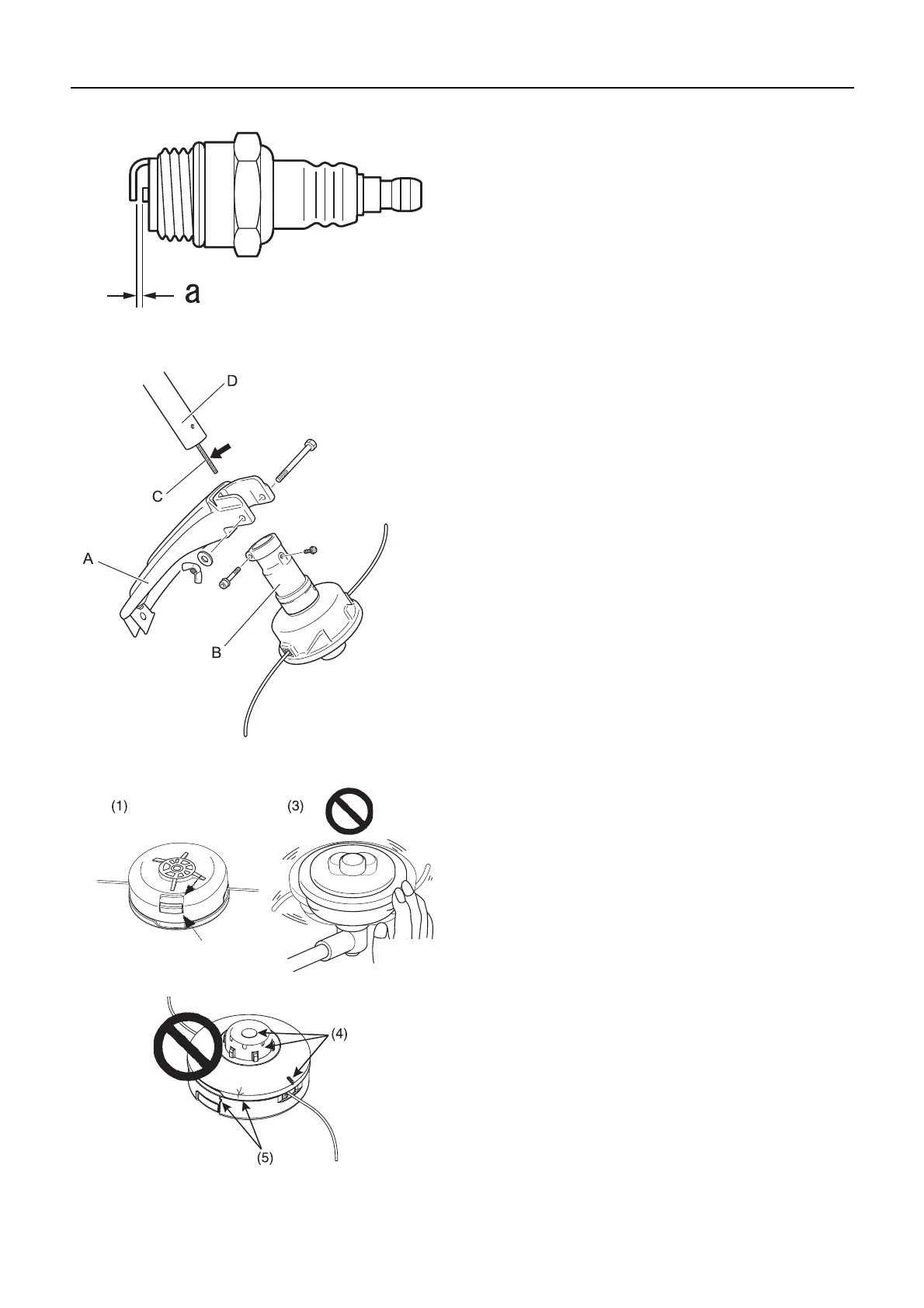

Check spark plug

1. Check plug gap. Correct gap is 0.6 mm to 0.7 mm.

2. Inspect electrode for wear.

3. Inspect insulator for oil or other deposits.

4. If the spark plug is dirty, clean it. Do not sandblast to clean.

Remaining sand will damage engine.

5. If the electrodes or terminals are worn, or if there are cracks

in the ceramics, replace them with new parts. (see Specifi-

cationspage 25)

6. Tighten to 15 N·m - 17 N·m (150kgf·cm to 170 kgf·cm).

The spark test (for checking whether the spark plug is spark-

ing) must be carried out by your dealer.

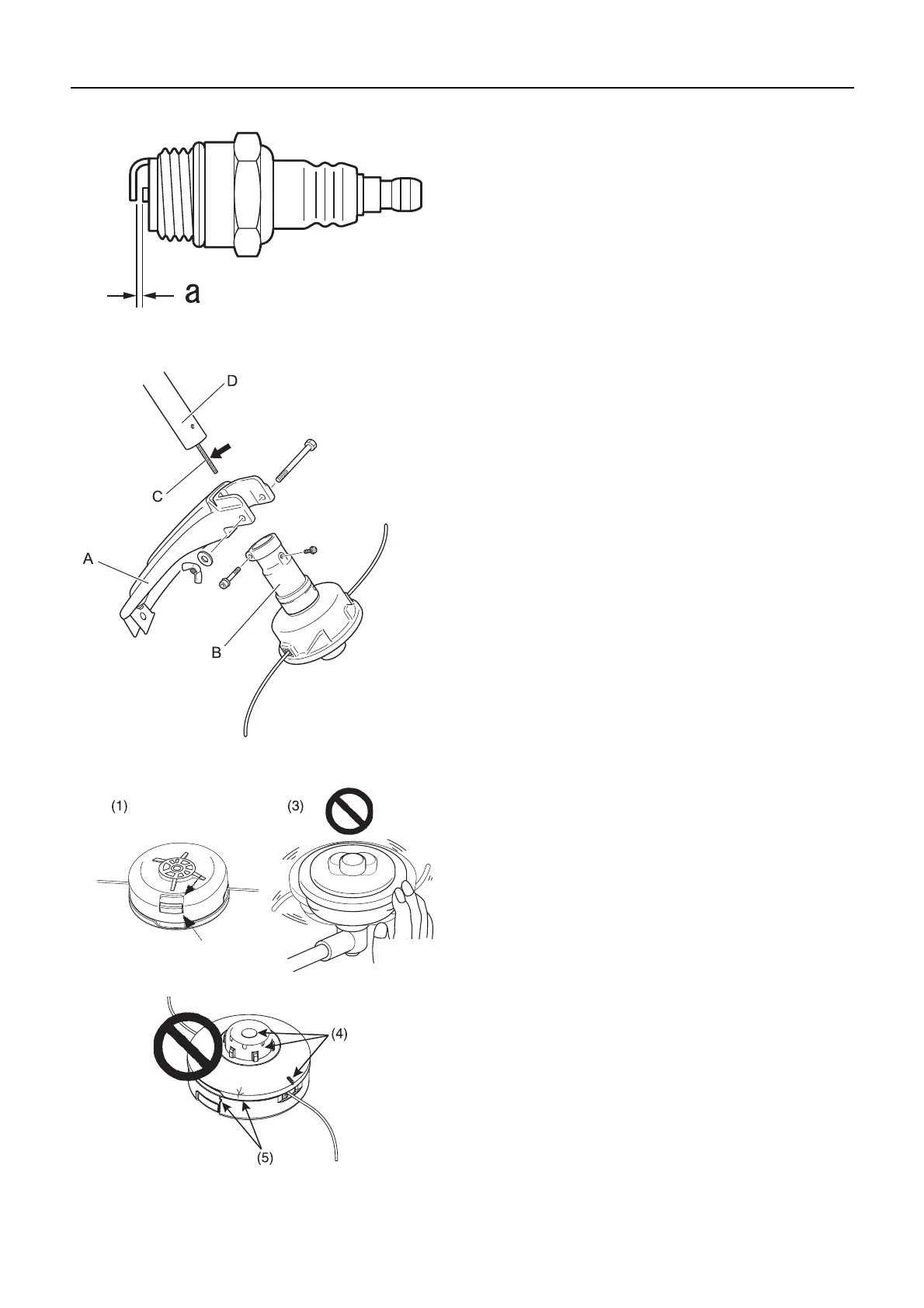

Lubricating drive shaft

1. Remove shield (A).

2. Loosen bearing housing (B) locating screw, at the top of the

housing, remove mounting screw.

3. Pull flexible shaft (C) from the shaft tube (D), wipe clean and

recoat with a thin coating 10 to 20 g, of lithium base grease.

4. Slide the flexible shaft back in the shaft tube. DO NOT get

dirt on the flexible shaft.

5. Install the bearing housing and shield.

Checking the nylon line cutting head

1. Make sure each periphery of the 2 retaining pawls of housing

spreads almost fully up to the outer periphery of the respec-

tive cover window.

2. Check mount of cutting head on trimmer and tighten if it is

loose.

3. Check the cutter head for deflection or abnormal noise rotat-

ing it by hand. Deflection or abnormal noise can cause ab-

normal vibration to occur or mount to trimmer to loosen

during rotation which is dangerous.

4. Inspect cover and tap knob for wear. When slot appears on

bottom of the tap knob or when slot appears on cover bottom

close to outlet for nylon line, replace them with new parts

without fail.

5. Check the cutting head for crack or chip. Replace parts that

show any crack or chip with new ones without fail.

Loading...

Loading...