21

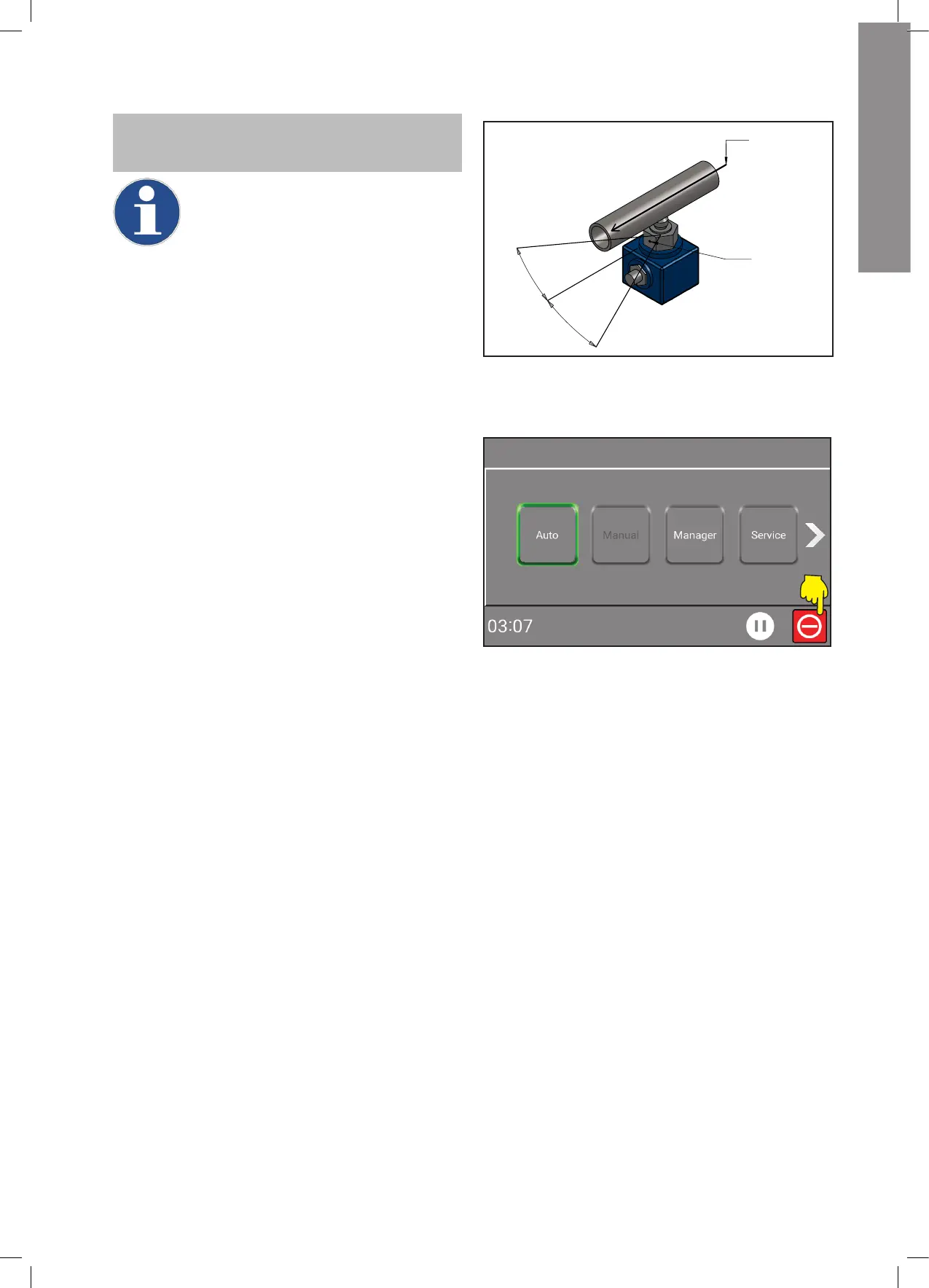

30°

30°

Flow

Mark

B

A

5

G

FF

E

A

B

C

D

E

C

D

1

1

2 3 4

1 of 1

Scale:

A4

Weight (g):

0,308

Tolerance:

Color:

DS/ISO 2768-m (medium)

Thickness (mm):

Approved by:

Last rev. by:

Drawn by:

Rev:

Desc:

Review or Prototype

Status:

No:

MAN. TEGN. FLOWSENSOR M. RØR

AMT

110002491

A-001

1:2

Initials:

Date:

Sheet:

Sheet size:

Material:

AKS

AMT

28.02.2012

24-01-2023

28.02.2012

Rev.

Date

Description

Fusioneret 3 man. tegn. til 1

A-

A-001

24-06-2019

24-01-2023

Mod. By

Admin

AKS

Ver. 3.00

CONFIDENTIALITY

NOTICE ! THIS

DRAWING

AND INFORMATION CONTAINED HEREIN ARE THE EXCLUSIVE PROPERTY OF

NILFISK FOOD

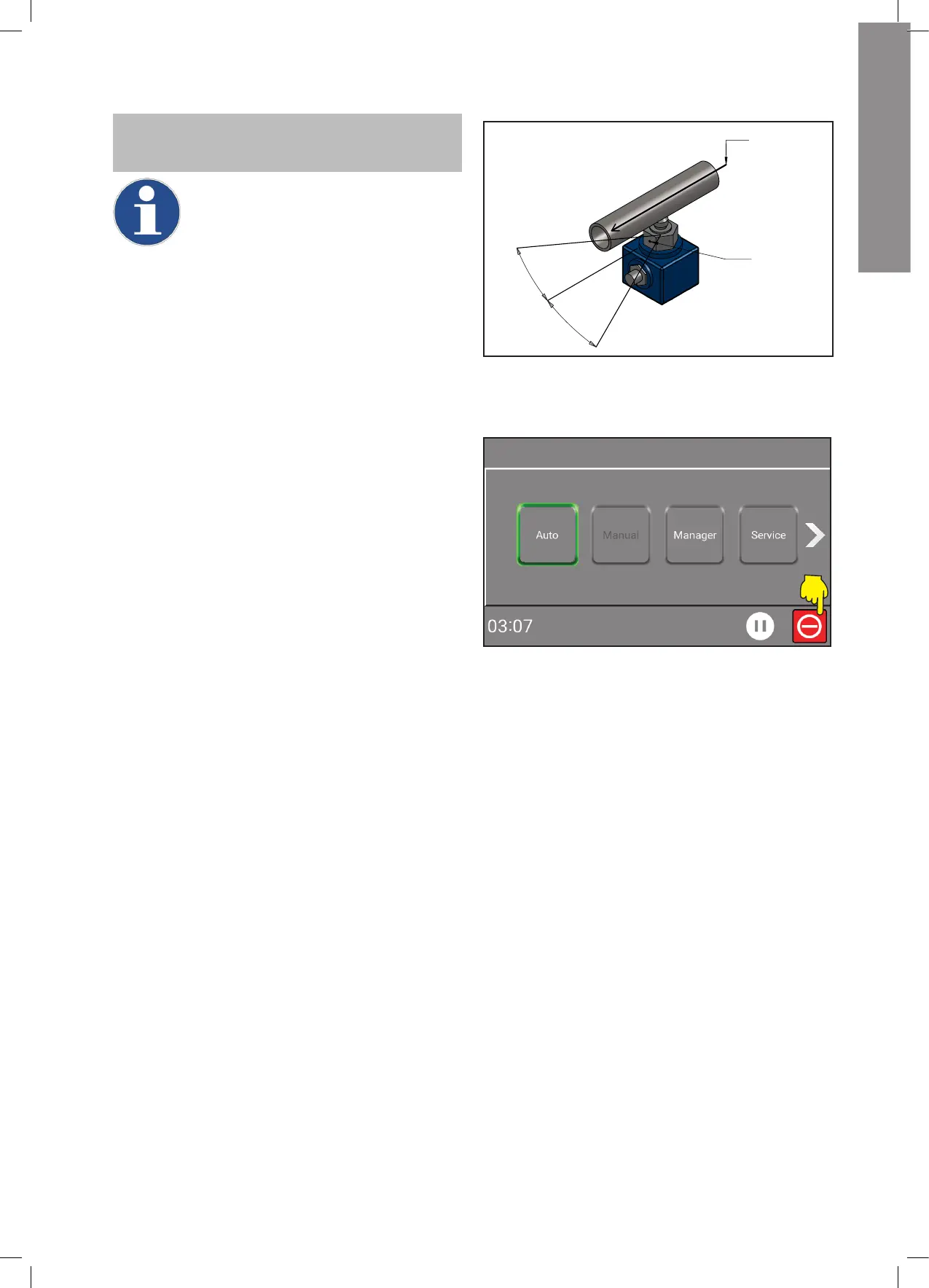

Flow switch calibration:

1.

the control display (refer to the image below).

PWash Program 1, 00:01:28

2.

3. Set the "rinse/foam" handle to foam position.

Turn the brass screw at the bottom until two

5.

7.

8.3.3. Pump/motor

• No maintenance needed.

• For further information see pump suppliers in-

struction manual.

8.3.4. Product solenoid valve

• No maintenance needed.

•

1. Turn off power supply.

2.

3. -

tion follows arrow tip pointing towards automatic

8. Maintenance, troubleshooting &

service

authorized and qualified personnel.

8.1. Maintenance personnel

Maintenance should be performed by an author-

This cleaning unit is compliant with EU regulations

-

8.2. Long production stops

secure the pump:

2. Apply a few drops of silicone oil to the axle between

the top section and the coupling.

Follow pump supplier manual instructions carefully.

Do not store or use the equipment in below freezing

temperature.

8.3. Components

8.3.1. Control system

No maintenance needed.

8.3.2. Flow switch

No maintenance needed.

Flow switch installation

• Ensure the dot on the sensor nut indicating the

contact point is within 30° parallel to the flow

direction (refer to image below).

•

used.

Loading...

Loading...