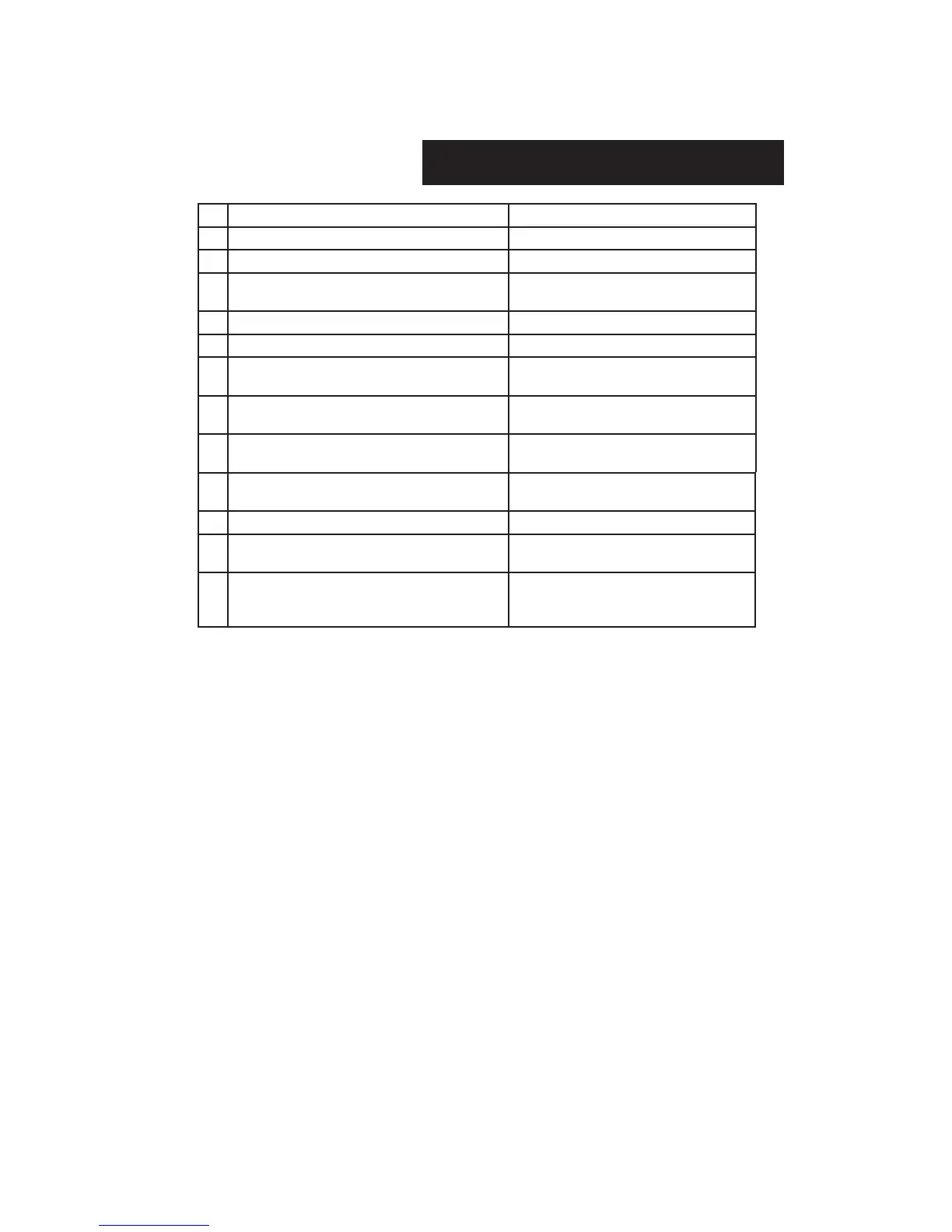

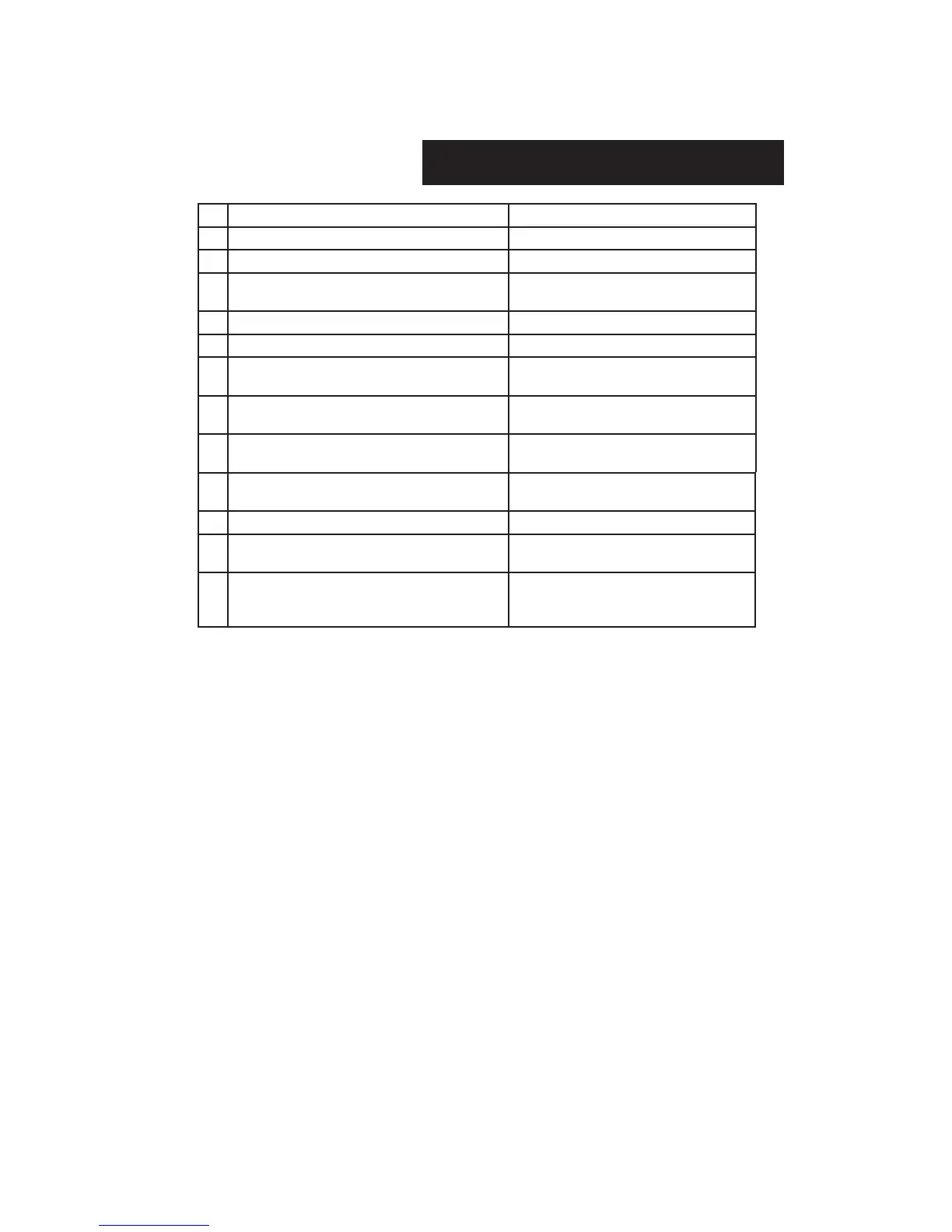

7

Owner’s Manual

1 Stainless steel blade with hinge #20141-001 (B-9x12 dimensions of tab)

2 Electromechanical Actuator #101, #101 XD, #101 XDS, #102 XD

3 Upper mounting bracket #15085-001 (116)

4 Space saver upper mounting bracket

(optional)

#50225-001 (117)

5 Lower mounting bracket #50014-001 (119)

6 RetroFit Kit bracket #15085-001 (116)

7 (Qty. 2) 5/16 #18 X 1-3/4" large hex head

bolt and 5/16

#10250-001

8 #123 L.E.D. Indicator Switch w/Retractor

(optional)

#15070-001 (123SC)

9 124SSR Standard solid state Tactile Switch

w/ Retractor (optional)

#15069-001 (124SSR)

10 #123 DR Dual Actuator L.E.D. Indicator

Switch w/Retractor (optional)

#15071-001 (123DRSC)

11 Shim kit (optional) #50015-002 (118S)

12 (Qty. 26) 1-1/4" (3.17 cm) stainless steel

sheet metal screw kit

#10002-001 (Kit #1)

13 (Qty. 6) 20 X 7/8" (2.22 x .63 cm)

stainless steel screws, ( Qty 6) flat washers

and (Qty. 6) 1/4" (.63 cm) lock nuts

Kit #4

Troubleshooting Guide

for Trim Tabs

Trim tabs do not work together,

independently or intermittently.

Solution Sequence:

1) I nspect fuse at fuse panel.

Replace if necessary.

2) Verify that all connections at switch

control box are tight and in place.

3) Make sure that switch assembly has a

solid ground.

4) If the actuator cables were spliced

inside the transom, inspect joint for

positive connection.

5) If, after following steps stated above,

the actuators still do not operate

properly — STOP and call the factory

for further assistance at 772-288-2662.

Additional Information

s#HECKELECTRICALCONNECTIONSBEHIND

switch and make sure ground wire is

in place.

s4HEADDITIONOFAZINCANODEWILLDETER

electrolysis. It is important that the zinc

is in contact with the trim tab blade.

s4ODISCOURAGEANYMARINEGROWTH

on tab or actuator, antifouling paint

can be applied. When applying paint

to the actuator, make sure it is fully

retracted. Do not paint the stainless

ram above the area that is exposed

when retracted.

s)FTABSMALFUNCTIONORTABSBECOME

stuck in the down position while

underway, remove pin or bolt at the

lower mounting bracket.

s4OREPOSITIONTHEACTUATORTURNSTAINLESS

steel ram clockwise and reattach.

Trim Tab System Parts & Troubleshooting

Loading...

Loading...