© Edwards Limited 2013. All rights reserved. Page 23

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

B800-00-880 Issue D

2.4 Purge gas specification

2.5 Cooling water

Refer to Table 9 for the cooling water specification. The cooling water supply should correspond to a typical high-

quality drinking water specification. Check with the water supply authority if there is any doubt about the quality of

the supply.

2.6 Materials exposed to gases pumped

The following materials and component types are exposed to the gases pumped: Aluminium alloys, stainless steels,

fluoroelastomer and nitrile O-rings, hydrocarbon lubricant, rare earth magnets, silicon nitride, carbon fibre

reinforced epoxy resin, fire retardant polypropylene, polyamide, PVC, Titanium, Silicon, Torlon and Ceramic.

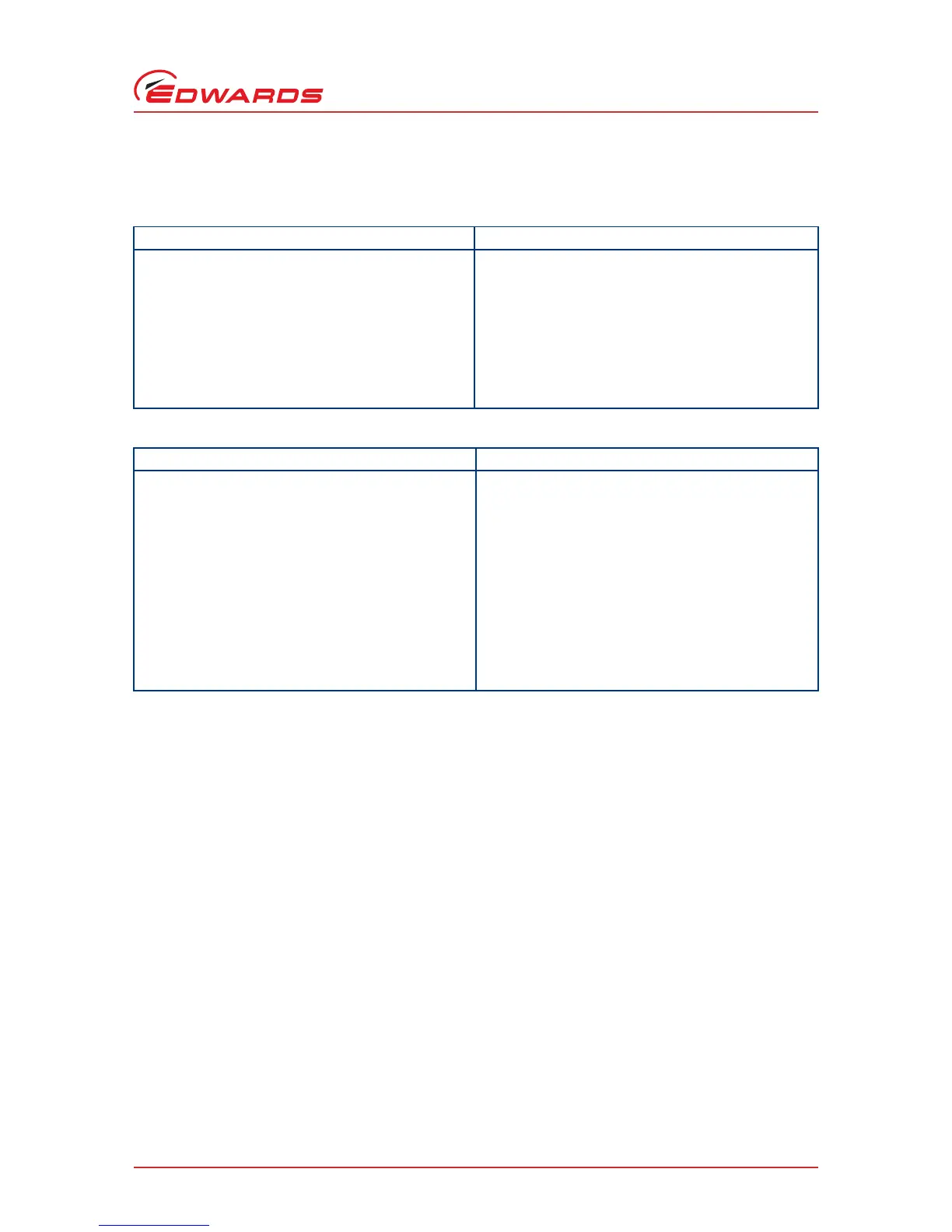

Table 8 - Purge gas specification

Purge gas specification Reference data

Purge gas Dry air, nitrogen, argon or other inert gases

Maximum dew point at atmospheric pressure -22 °C

Maximum size of particulates 1

µm

Maximum concentration of oil 0.1 parts per million

Allowable purge gas flow (when required) 20 to 50 sccm (0.33 to 0.84 mbar l s

-1

or 33 to 84 Pa l s

-1

)

Recommended purge gas flow 25 sccm (0.42 mbar l s

-1

, 42 Pa l s

-1

)

Maximum allowable purge gas supply pressure 1 bar (gauge); 14.5 psig, 2 x 10

5

Pa

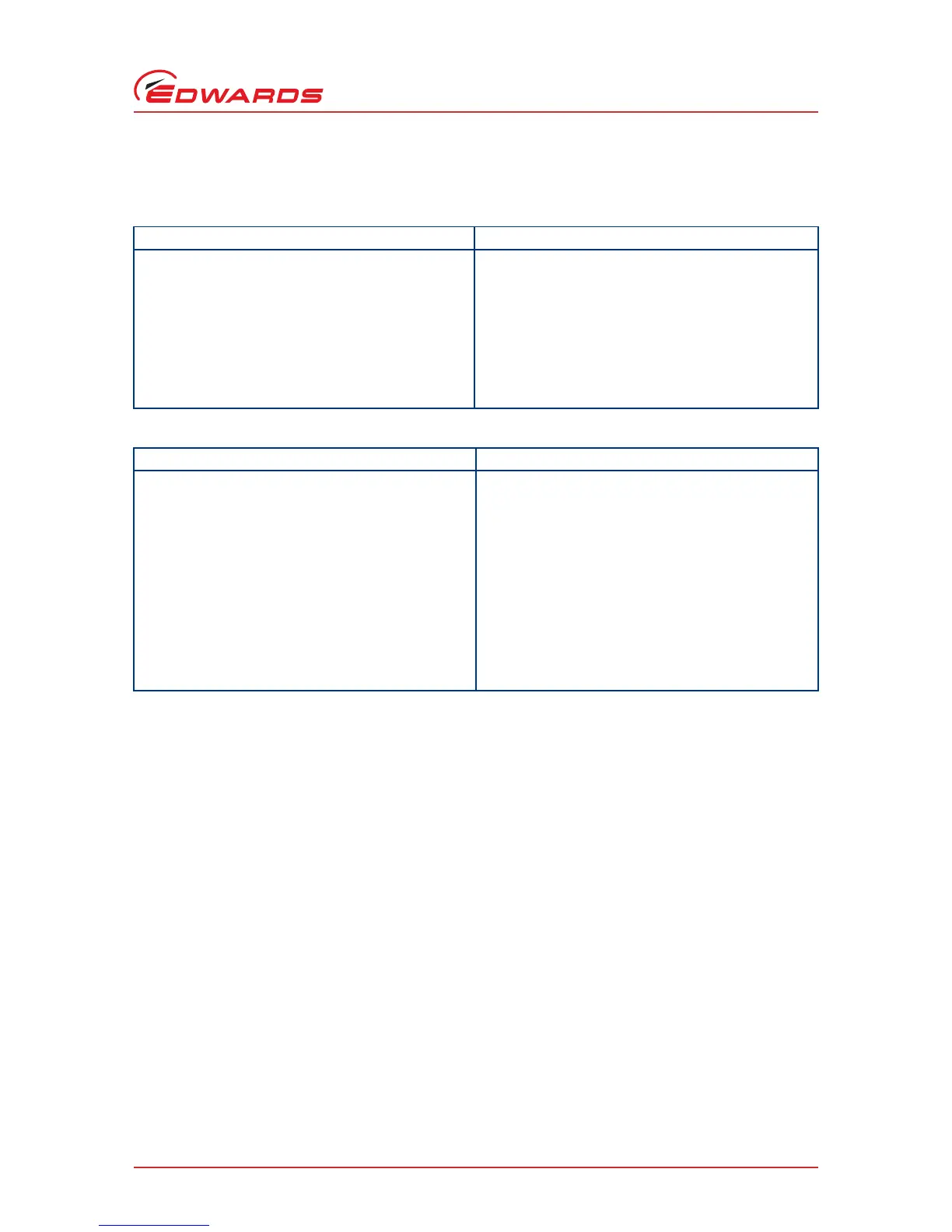

Table 9 - Cooling water specification

Cooling water specification Reference data

Quality Mechanically clean and optically clear with no deposits

or turbidity

pH value 6.0 to 8.0

Maximum calcium carbonate concentration 75 parts per million

Maximum chloride concentration 100 parts per million

Minimum oxygen concentration 4 parts per million

Minimum cooling water flow rate (at 15 °C) 15 l hr

-1

Water temperature 10 to 20 °C

Maximum water pressure 5 bar (gauge), 73.5 psig, 6 x 10

5

Pa

Materials exposed to cooling water Nickel plated brass

Loading...

Loading...