Send a command through the serial interface to close the vent valve before you send a

st

art command. This is known as a delayed start.

If you control the pump with the manufacturer's TIC Turbo and Instrument Controller or

TIC Turbo Controller, the TAV solenoid valve can be operated from the TIC. Refer to the

TIC Instrucon Manuals for more informaon.

4.9.4 Alternave valve connected to the vacuum system

If you use dierent vent valve, make sure that the applicable vent restrictor is installed in

the vacuum system to limit the rate of increase in pressure. Refer to Table: Vent

restrictor orice diameter (with atmospheric pressure at the inlet of the vent valve) for

informaon about the sizes of vent restrictor. If the applicable vent restrictor is not

installed, open the vent valve only when the speed of the pump decreases to 50% of the

full rotaonal speed.

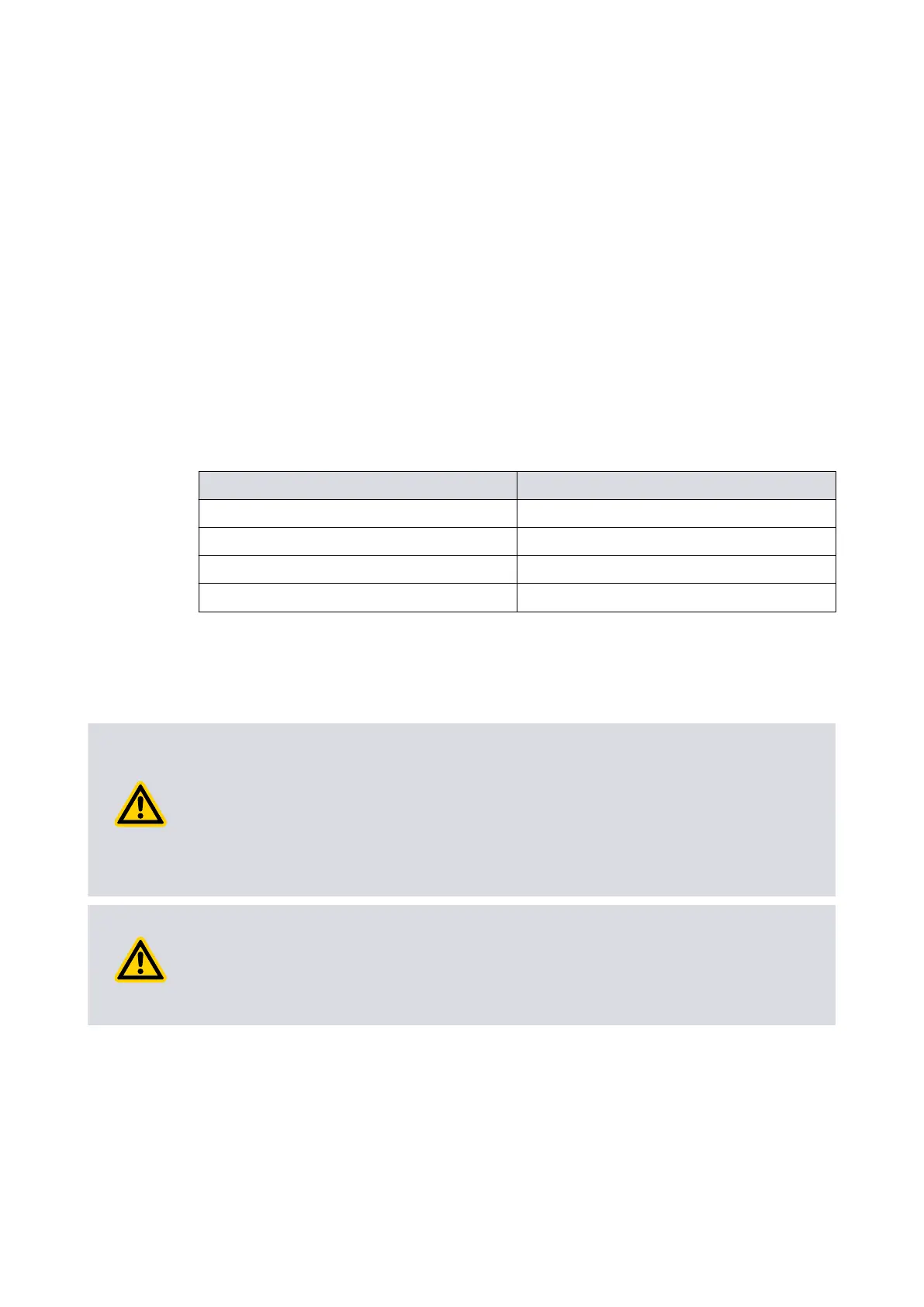

Table 19

Vent restrictor orice diameter (with atmospheric pressure at the inlet of the vent

valve)

Vacuum system volume (litres) Orice diameter (mm)

< 20

£ 1.0

< 10

£ 0.7

< 5

£ 0.5

< 2

£ 0.35

4.10 Cooling

4.10

.

1 Introducon

CAUTION: PUMP COOLING

Risk of damage t

o equipment. Make sure that the pump is suciently cooled to

prevent the damage to the rotor and bearing.

When you use an alternave conguraon (other than the manufacturer's standard

cooling accessories) to cool the pump, make sure that the cooling is not directed or

ducted onto the pump controller.

CAUTION: VENTILATION FOR PUMP

Risk of damage t

o equipment. If the pump is in an enclosure, make sure that

sucient venlaon is available. The ambient temperature around the pump must

not be more than 40 °C.

▪ Natural convecon cooling: For the light pumping dues, with an ambient air

temperature less than 30 °C, natural convecon cooling can be sucient to cool

the pump.

▪ Forced air cooling: The ambient air temperature must be 5 °C to 35 °C when you

use the forced air cooling. make sure that there is sucient supply of cooling air to

the pump.

04/2022 - ©Edwards Limited

Page 60B80000880_G

B80000880_G - Installaon

Loading...

Loading...