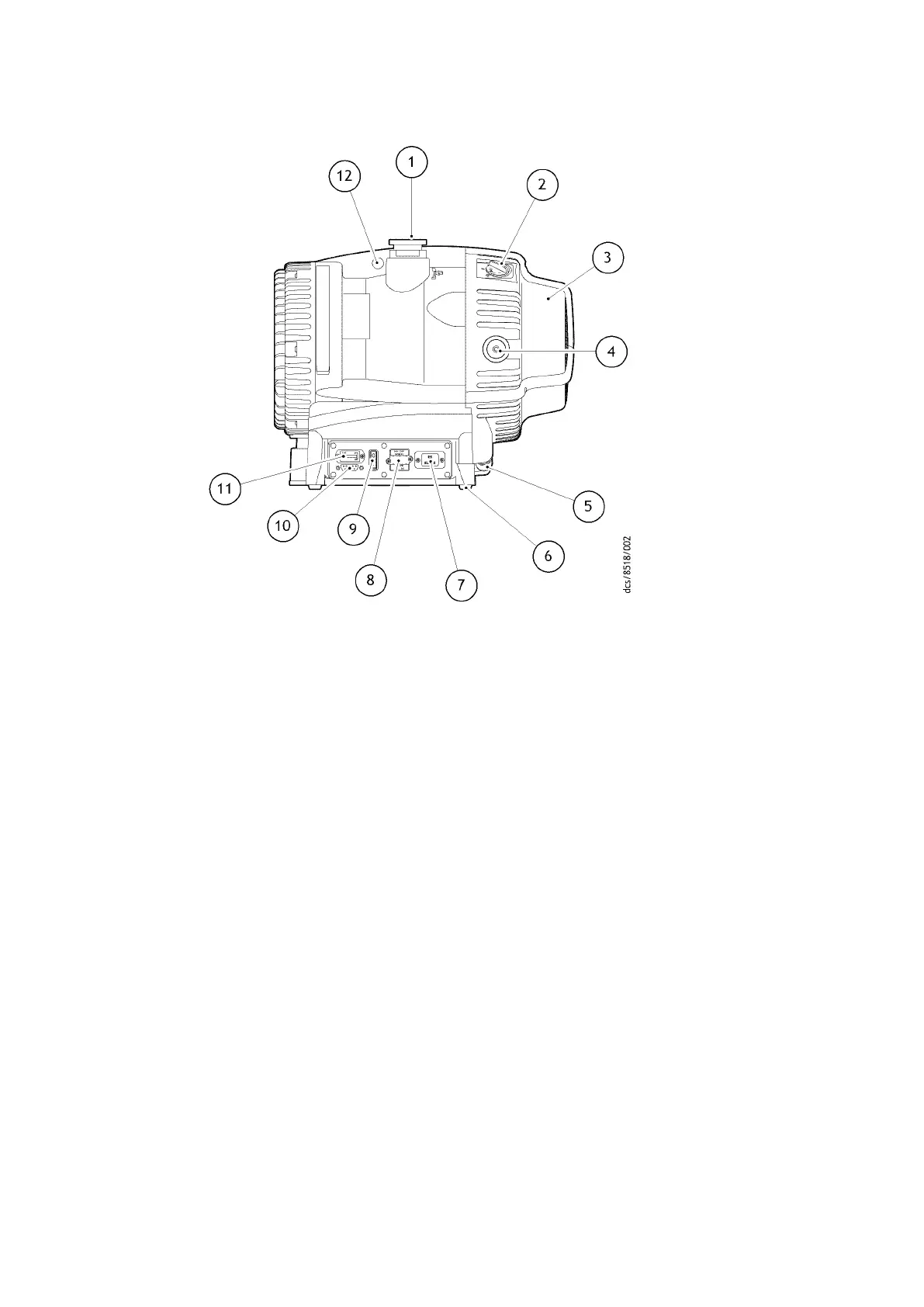

Figure 1 General view

1. NW40 inlet port 2. Gas ballast control

3. Cooling fan 4. NW25 exhaust port

5. Fan connector 6. Rubber feet

7. Electric connector 8. Voltage changeover switch cover

9. Run/Standby switch 10. 15‑way connector

11. Hour counter 12. Liing eye

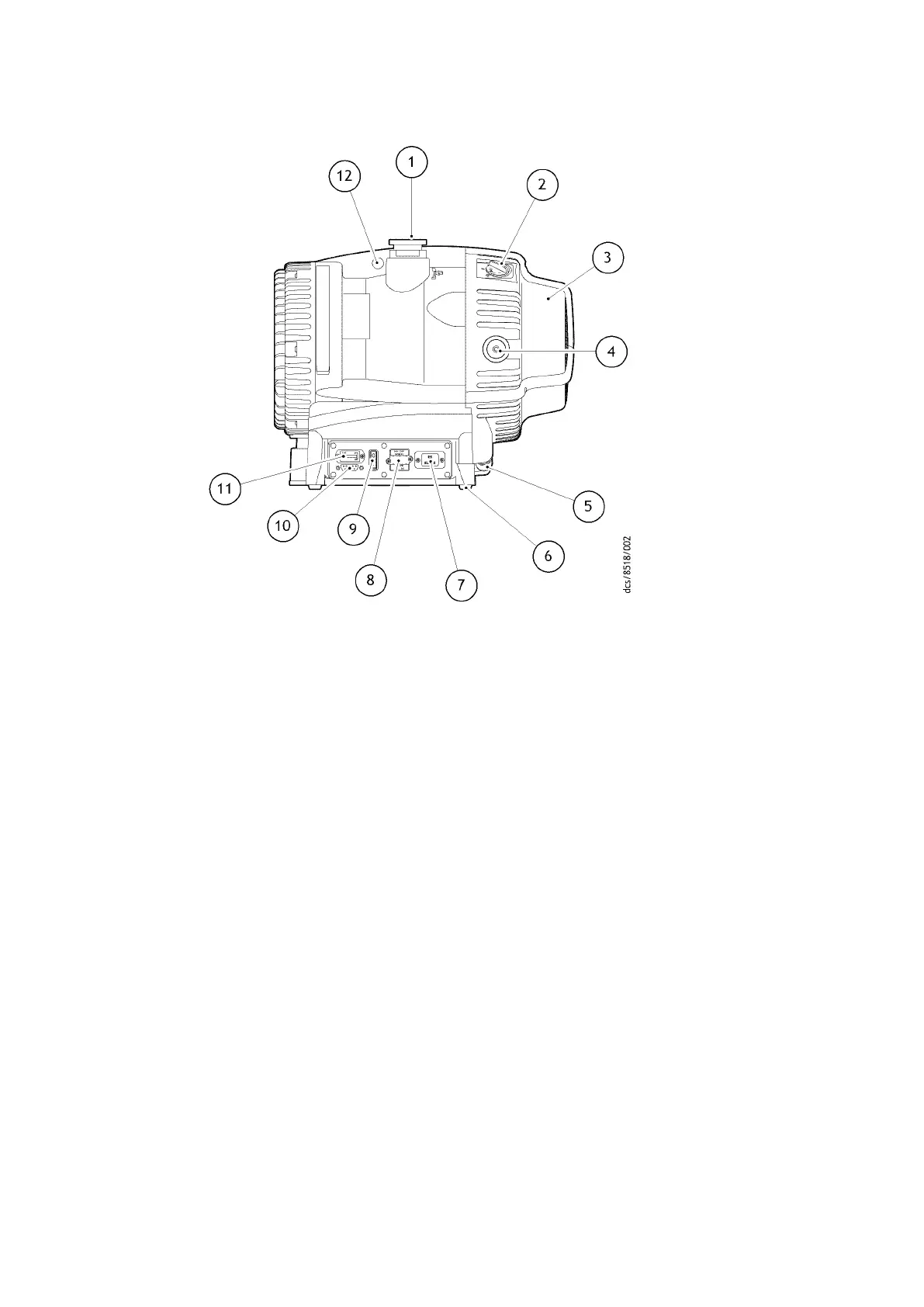

1. NW40 inlet port 2. Gas ballast control

3. Cooling fan 4. NW25 exhaust port

5. Fan connector 6. Rubber feet

7. Electric connector 8. Voltage changeover switch cover

9. Run/Standby switch 10. 15‑way connector

11. Hour counter 12. Liing eye

2.3 Descripon

Refer to Figure: General view on page 9 for item numbers in brackets in the following

descripons.

The XDS pump is a compact, reliable vacuum pump which is suitable for use on vapour

handling processes. It may be used for some pumping applicaons involving corrosive

substances and parculates; for informaon on pumping ammable gases, please refer

to Implicaon of ATEX direcve on page 22 and contact us for any further assistance.

The body of the pump includes a xed scroll and an orbing scroll. The orbing scroll is

controlled by the electric motor through an eccentric cam on the motor drive sha. The

movement of the orbing scroll, meshed with the xed scroll, forms successive crescent

shaped volumes in the pump. Gas that enters the pump through the inlet is compressed

by the movement of the orbing scroll and swept towards the centre of the xed scroll.

The compressed gas enters the exhaust port near the centre of the staonary scroll and

is exhausted from the pump through the outlet.

The XDS is a dry vacuum pump, as all the bearings, with hydrocarbon lubricant, are

isolated from the vacuum space. The pump has an NW40 (item 1) inlet and inlet strainer.

The pump mechanism is driven directly by a three-phase electric motor. The motor is

Page 9

A73101880_F - Introducon

Loading...

Loading...