To release the sheet metal, flick the material upwards, which will lift the clamp bar to make

ready for the next bend. It may be necessary to lift the clamp bar by using one of the lifting

handles.

CAUTION

Do not insert small items under the clamp bar – a minimum bend of 15mm is essential except

when bending very lightweight soft metal. This will prevent damage to the clamp bar.

To get the best performance do not clamp longer than is necessary due to the magnet having

less clamping force when heated.

HOW TO USE THE BACKSTOPS

Make use of the backstops when handling volume bends that are all the same size. Set the

backstops at the size required.

Backstops can be used with a bar (not supplied) laid against them, making a long surface to

use as a reference. The extension pies from the bending beam could be used.

Use a strip of sheet metal of the same thickness as the work piece if a backstop is required

under the clamp bar.

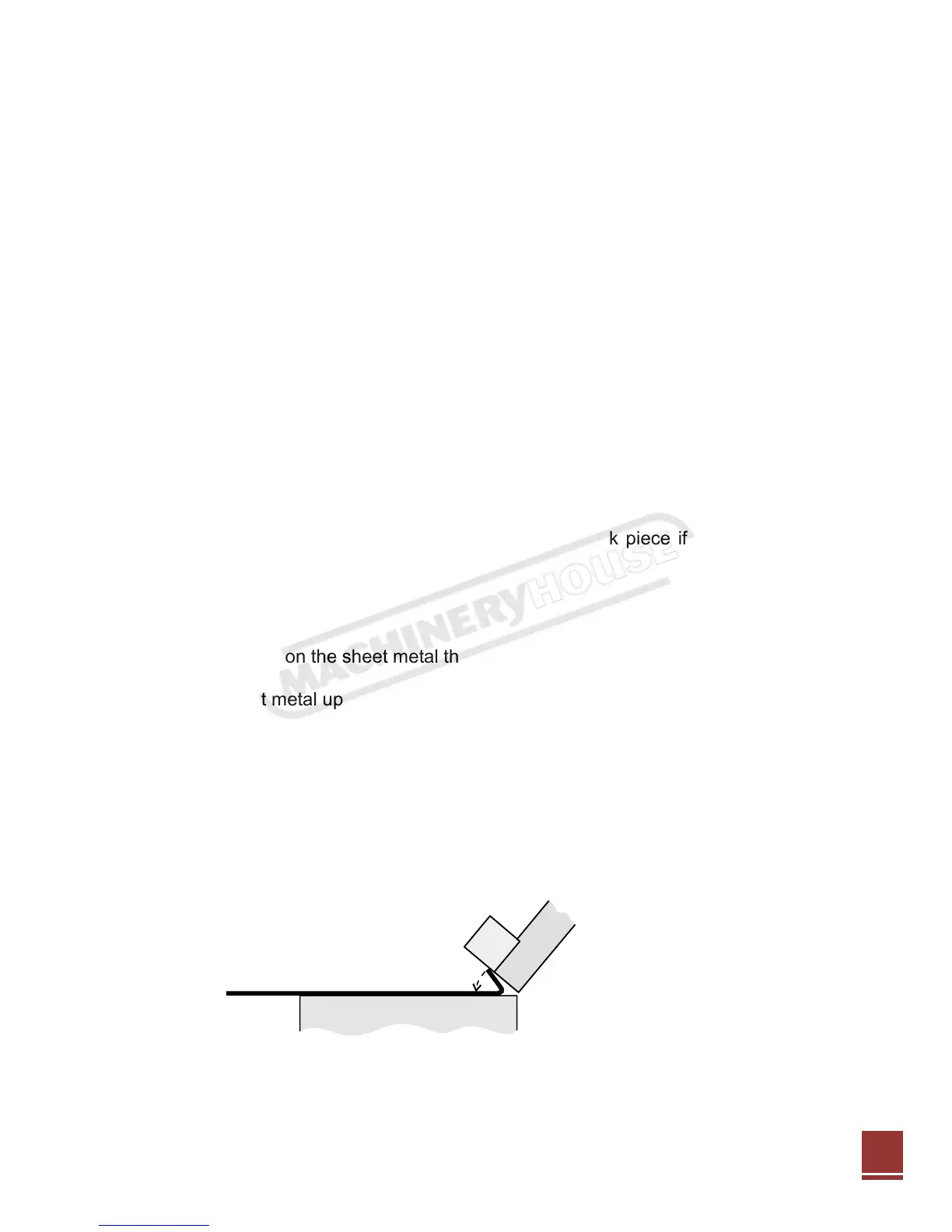

HOW TO FOLD A LIP

Folding the lip will depend on the sheet metal thickness and the length and width.

Lightweight sheet metal up to 0.8mm.

1. Carry out instruction for standard bending and continue to bend as far as possible. Move

the angle stop collar up to the top of the handle, and tighten the Allen head screw to

keep it there.

2. Take away the clamp bar, leave the sheet metal on the machine and move 10mm

backwards, bring over the bending beam and compress the lip. No clamping is required.

Thick sheet metal is not suitable for this application.

3. Further flattening can be accomplished when using thin lightweight material by following

up with magnetic clamping

Instruction Manual for EB2500 (S5321)

Loading...

Loading...