12 0

Page

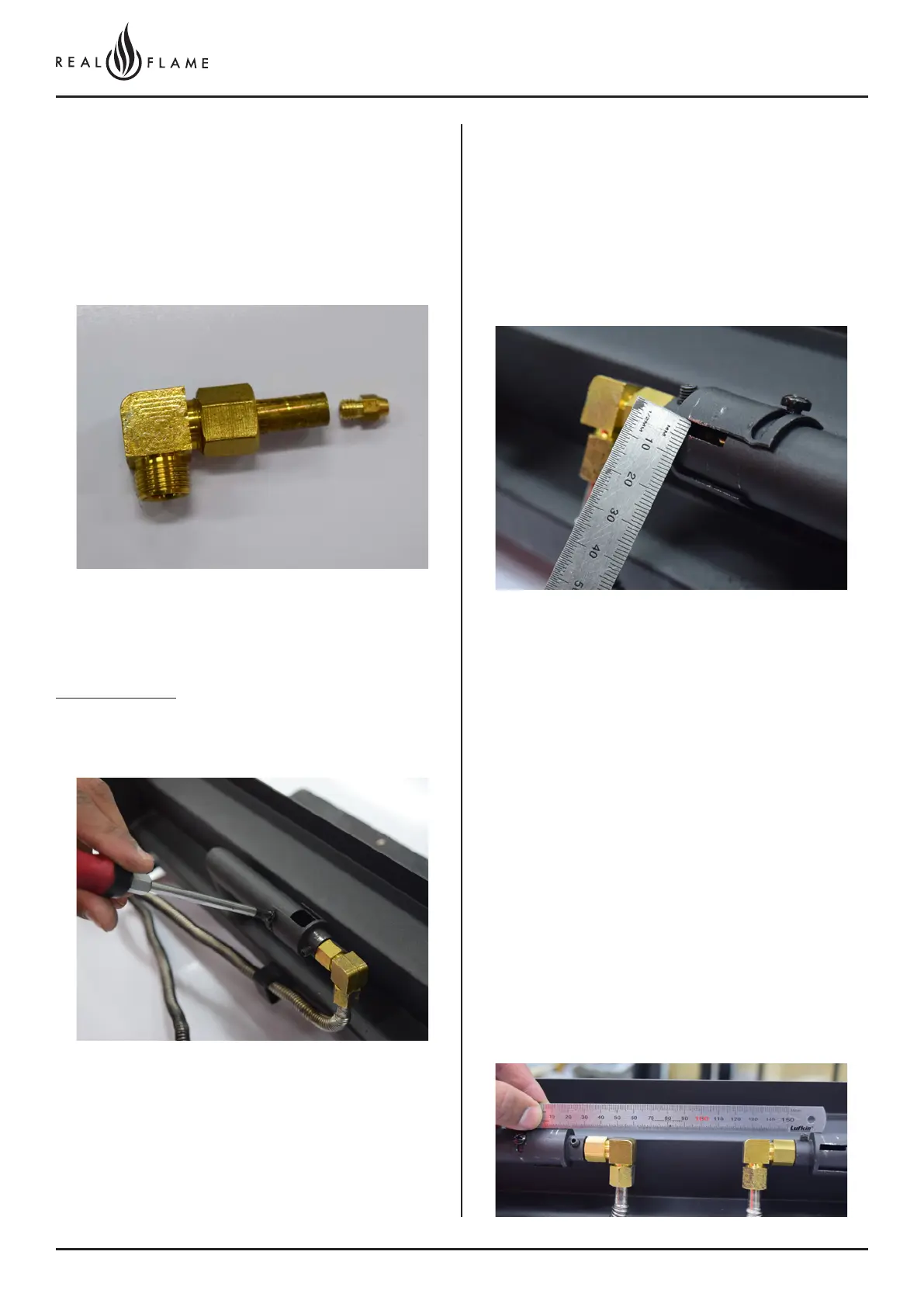

Loosen aeration cap screw approx. ½ turn. Rotate cap

until the correct gap is achieved to suit the gas type. The

listed opening is required on each side of the aeration

cap. (A ruler or similar can be used to check the opening,

a drill bit of the designated size can also be inserted to

check the opening). Tighten screw to retain aeration cap

setting.

Aeration Setting

Natural Gas- 3.0/3.0mm open

LPG- Full open / Full open

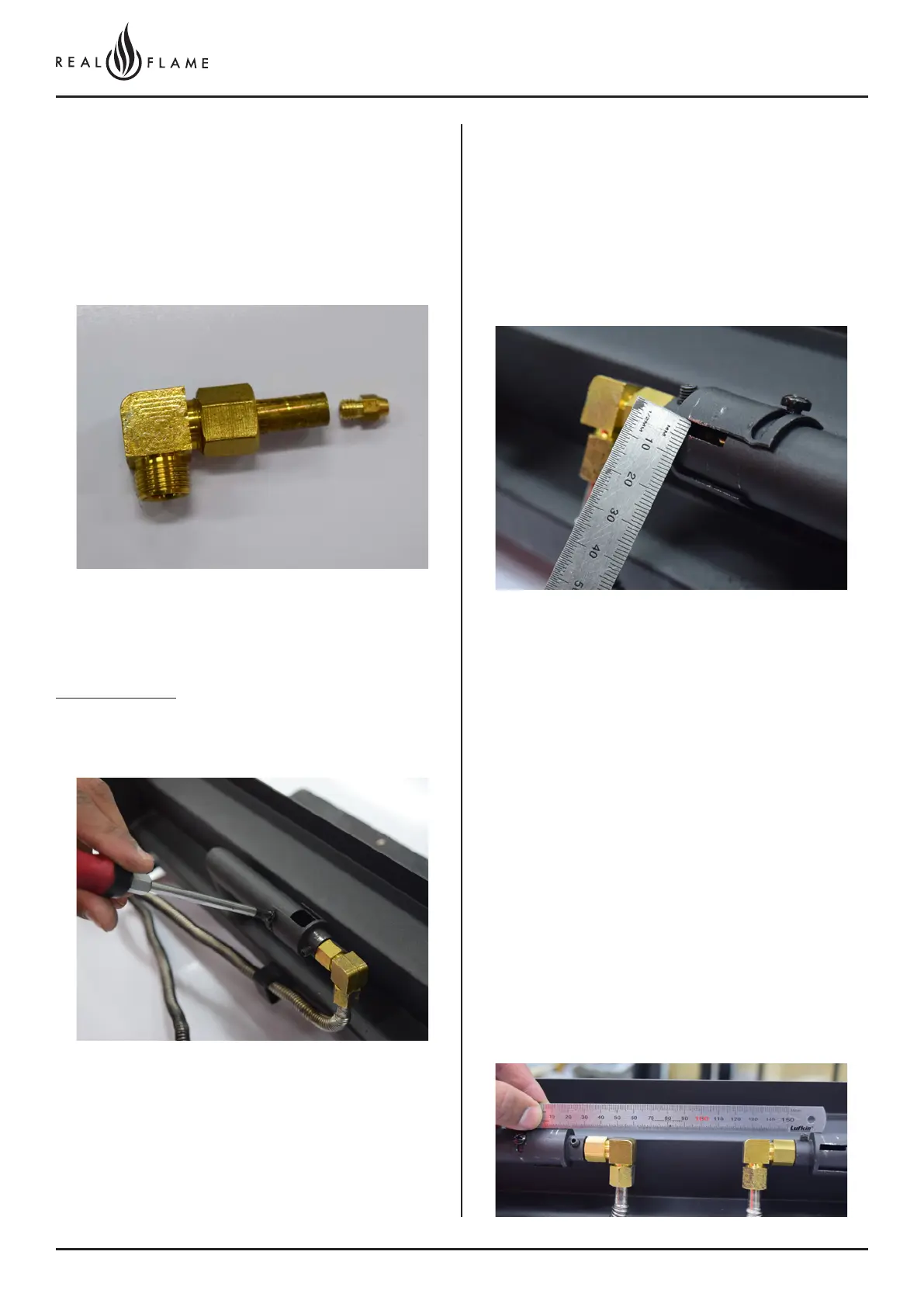

Refit injector assembly into aeration cap.

Refit gas pipe and tighten nuts.

Ensure injector assembly is sitting firmly into aeration cap

and tighten grub screw.

Note – ensure injector assembly is aiming centrally into

the aeration cap and tube

Correct where required.

Rotate burner to check insulation is correctly located.

The burner consists of two types of insulation.

In the event the lower insulation (white glass wool blanket)

has moved push firmly down and ensure blanket fills all

gaps and corners of the burner.

Sit 12mm hard insulation back into burner. Hard

insulation should sit loosely onto the top of soft insulation

approximately level with the burner. Where required

adjust the soft insulation to ensure sitting correctly. TAKE

CARE – where the burner has been previously used the

hard insulation is easily cracked.

The insulation media can be repainted using an approved

high temperature paint, contact Real Flame for details.

Loading...

Loading...