12 2

Page

PILOT RE-FITMENT

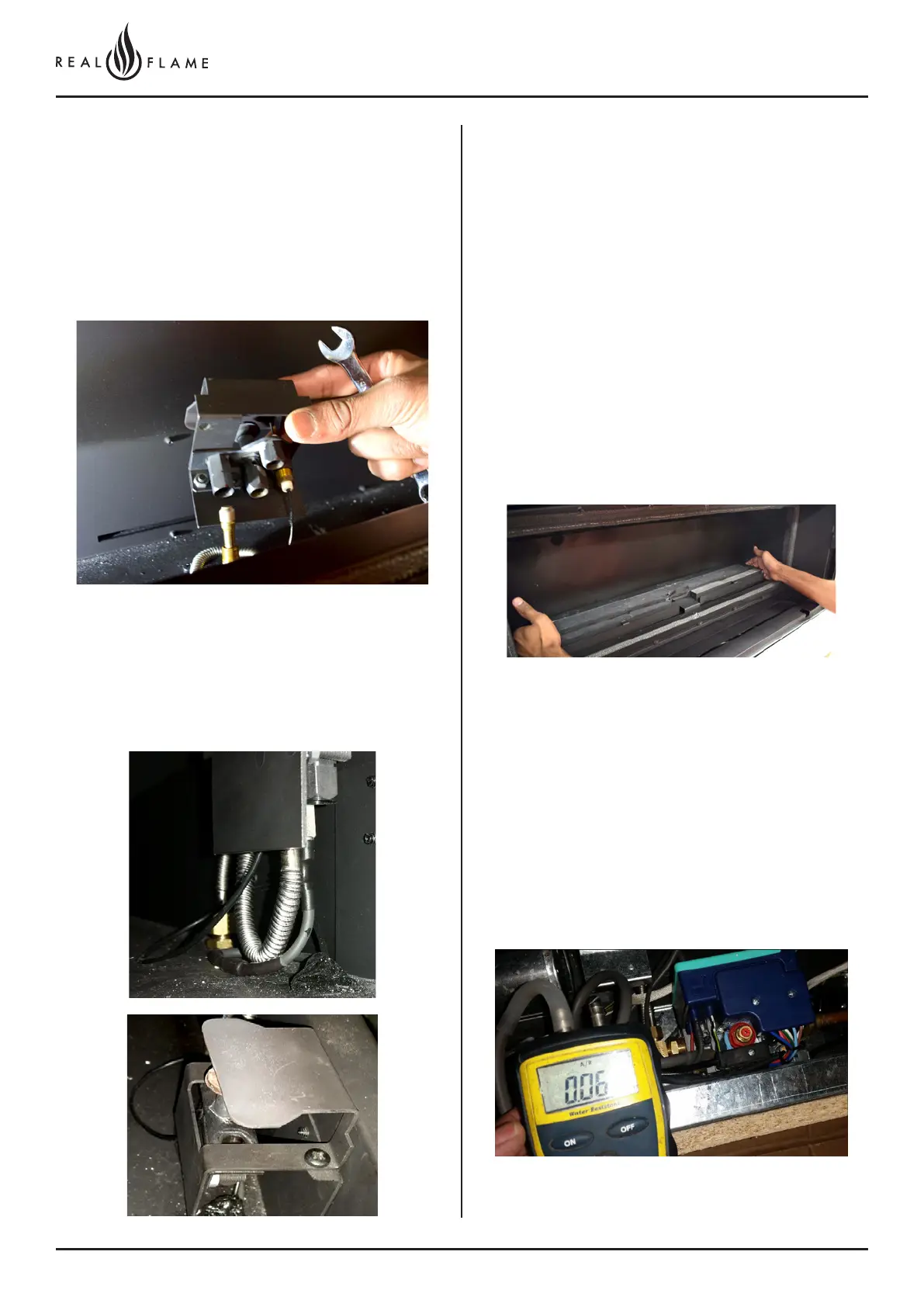

Replace pilot orifice with correct gas type.

Refit pilot gas pipe and tighten

Refit spark probe and gently tightly

Refit spark lead

Push pilot assembly down to original position and refit the

bracket retaining screw.

Check all wires are sitting correctly, flush to front wall.

Ensure spark lead is not broken or excessively bent.

Ensure lead hole is still sealed. (High temperature silicon

is suitable for resealing.)

BURNER RE-FITMENT

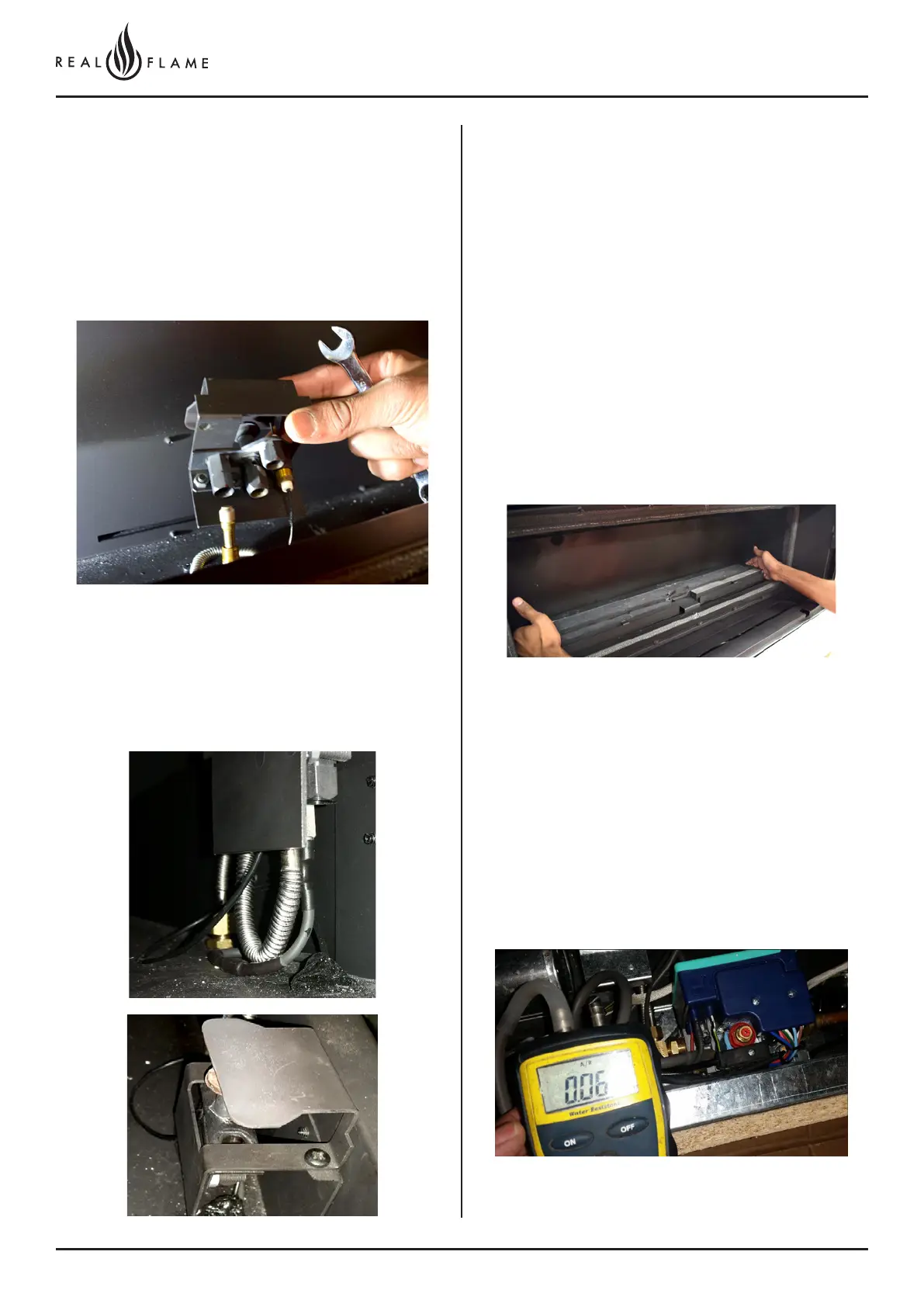

Carefully place burner into firebox, supporting LH end of

the burner.

Tighten gas pipe connection to the end of the burner.

Burner can now be lowered fully into the firebox.

Refit burner retaining screws (2 off)

Refit End cover plates and refit holding screws.

(Screws only need to be done finger tight)

Replace media as per media fitment instructions.

Refit door. Check door seal is sitting correctly.

Hang door onto firebox. Fit screw and lift door slightly to

locate.

10 x screws to be refitted

DO NOT OVER-TIGHTEN SCREWS – Hand tight is

sufficient for door to seal.

Fit manometer to appliance.

Start appliance and check for gas leaks in lower area

and in firebox.

Adjust high and low burner pressures to the data-plate.

(The appliance must operate for 3minutes before high

pressure setting can be obtained).

Loading...

Loading...