59

Page

Setup with internal fan module with wall

termination – appliance mounted

Maximum 9m flue length

Wall termination

1. Wall terminal must be installed with clearances as

specified by AS5601.1-2013 Clause 6.9.3

2. Run exhaust flue and air intake flue as required –

Maximum run 9m per flue. Flues can be run next to

each other. Maintain clearances to combustibles.

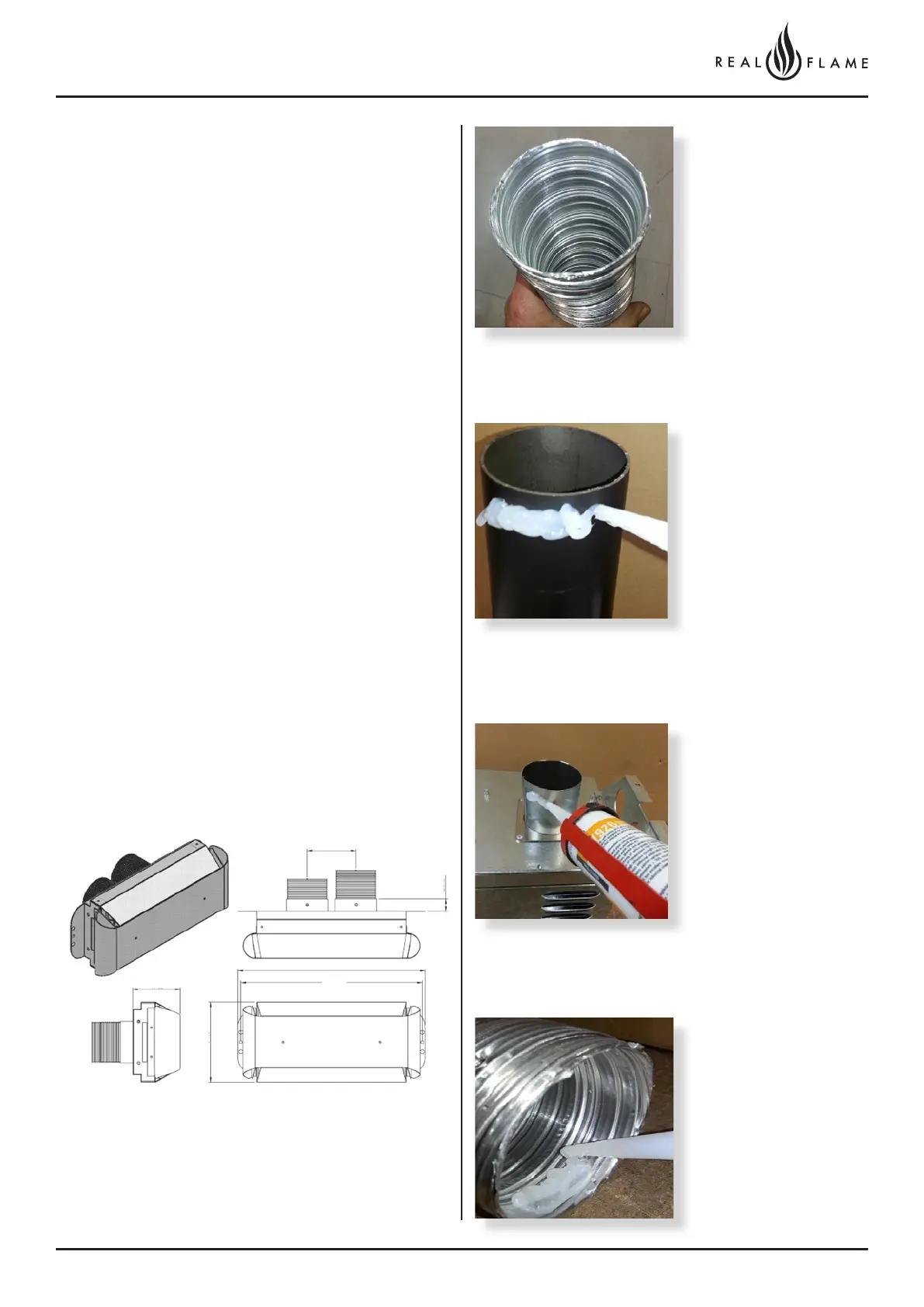

3. Insulation Instructions-

Exhaust flue must be insulated using 25mm glass wool

pipe insulation as supplied by Glen Dimplex Australia.

Insulation must be fitted to exhaust (hot side only).

Insulation must start as close to appliance as possible

(within 300mm).

Insulation must finish as close to discharge as possible

(within 300mm).

Insulation must run around bends.

Insulation to be taped to ensure no gaps.

Insulation may be fitted while running flue or at final

stage of installation.

(shown at flue stage in Instructions)

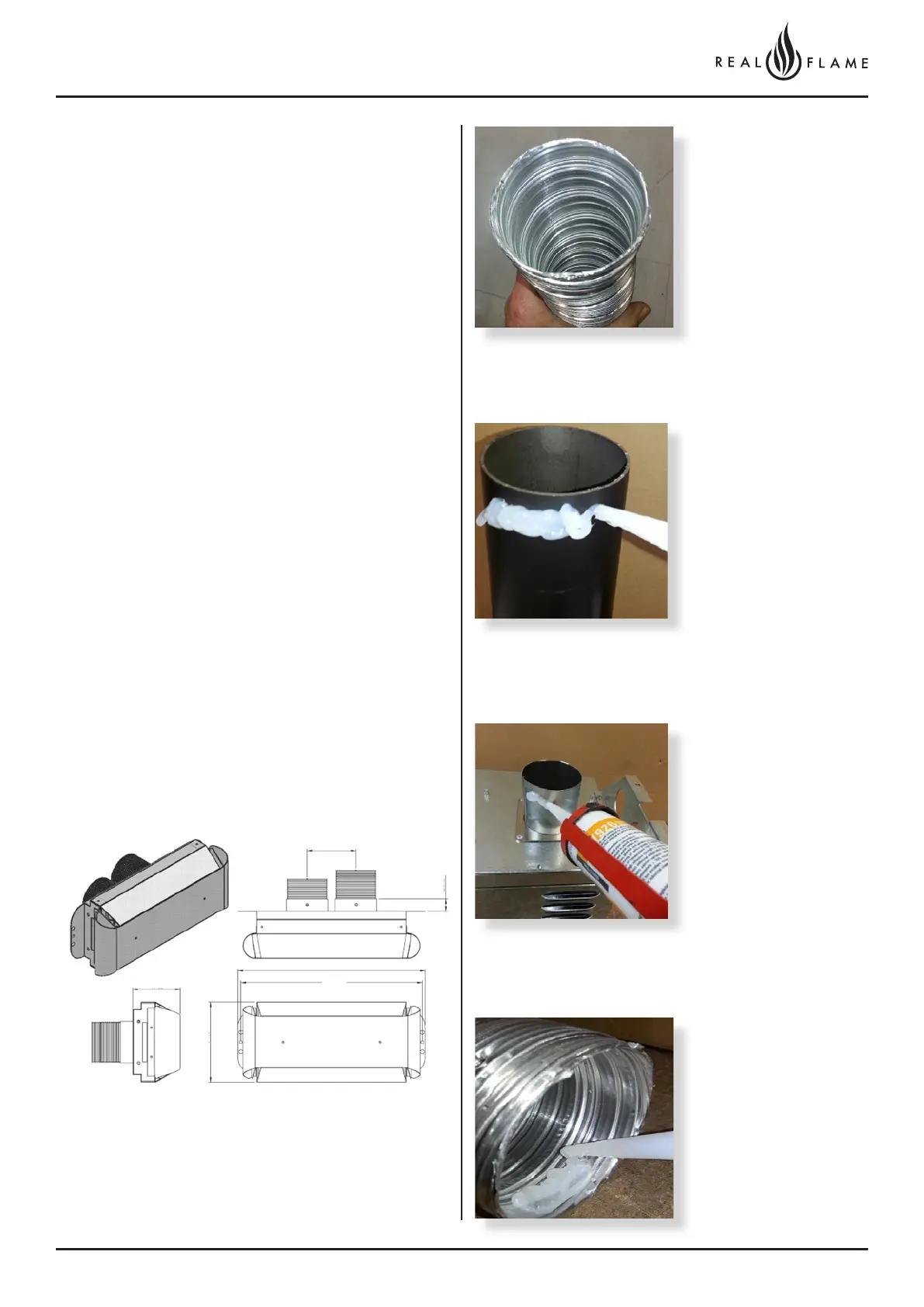

4. Connection to appliance

Check 75mm flue piece

for correct shape and

fitment onto appliance

spigot.

Ensure ends are burr free

and round, test fit flue will

slide over the connection.

Recommended Silicon

– Non-acetic, neutral

cure 150degc or higher

temperature rated.

Bostik RTV 926 or similar.

Apply an 8mm thick silicon

bead fully around heater

connection approx. 10mm

from the top.

Apply an 8mm silicon

bead fully around the

inside of the flue end, both

ends.

Apply an 8mm thick

silicon bead fully around

the lower fan connection

spigot approx. 10mm from

the end.

100

383

97

371

25

164

Loading...

Loading...