61

Page

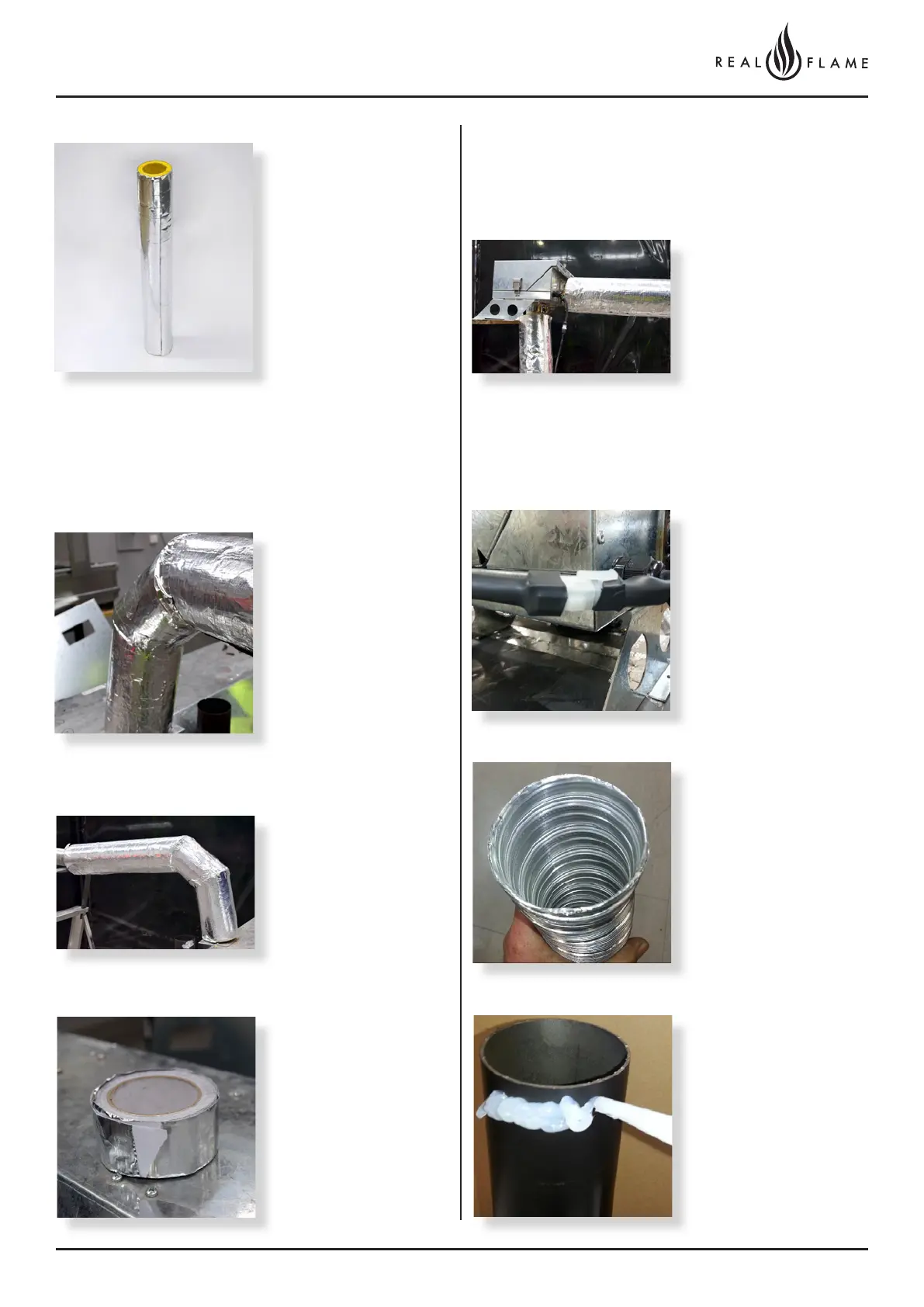

Insulation must start as close to the gas space heater as

possible

(Only exhaust flue is to be insulated)

Insulation to be fully closed

and sealed along length.

Bends where practical

should be insulated, by

cutting the insulation into

segments and taping

together.

Fit flue exhaust insulation

For all Element 900

installations using inline

fan configurations (where

flue length exceeds 3m),

the first 3m (or up to 3m)

of exhaust flue must be

insulated with 25mm foil

faces glasswool pipe

insulation, as supplied by

Glen Dimplex Australia.

Joins can be taped

together using aluminum

foil self adhesive tape.

Insulation may be fitted

prior and after the inline

powerflue fan.

Failure to fit insulation on the exhaust flue may result in

condensation failures with the appliance.

Insulation to be run for the first 3m from the appliance. For

flue runs shorter than 3m, discard extra insulation.

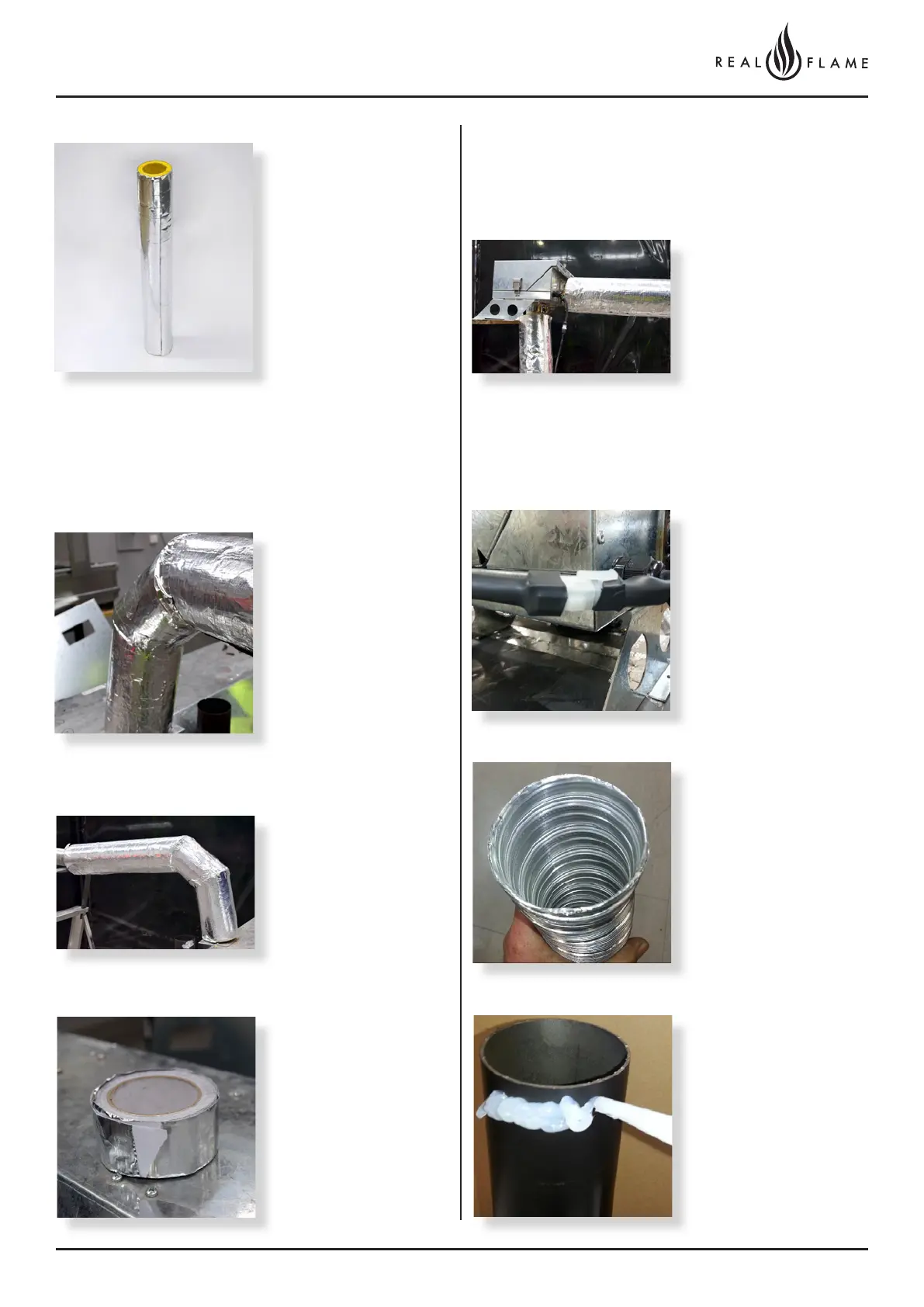

Connect power lead to

fan module. Ensure lead is

clipped to support where

required.

Do not use connection to

support lead.

Fit air intake flue pipe to

heater connection.

Cut tube to length where

required.

Ensure ends are burr free

and round, test fit flue will

slide over connection.

Apply an 8mm thick silicon

bead fully around heater

connection approx. 10mm

from the top.

Loading...

Loading...