68

Page

Locate terminal on wall and predrill mounting holes where

required.

Cut flue exhaust tube (hot tube) to length (Flue must

extend a minimum of 50mm past the exit face of wall.) It

is recommended that the tubes are cut slightly longer and

pushed back into wall upon fixing of wall terminal. Allow

flue movement between terminal and last flue hanging

clip.

Cut Air intake as per flue exhaust.

Ensure ends are burr free and round, test fit flue will slide

inside both the hot exhaust connection and air intake

connection.

Feed hot exhaust flue

into connection, ensure

inserted 50mm. Fit retaining

screw from below.

Feed air intake flue

into connection, ensure

inserted 50mm. Fit retaining

screw from below.

Insulation must start as close to the gas space heater as

possible

(Only exhaust flue is to be insulated)

Insulation to be fully closed

and sealed along length.

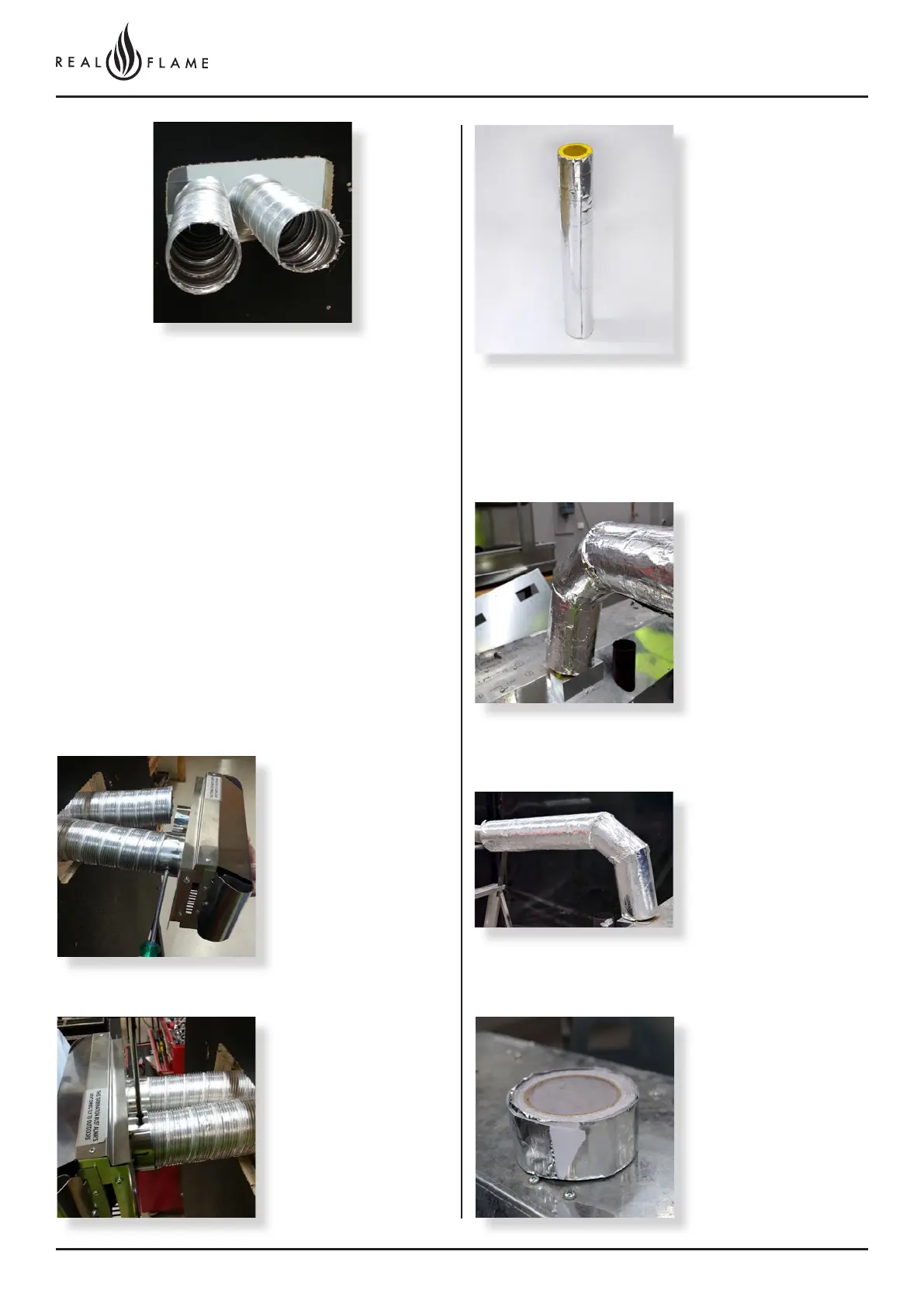

Fit flue exhaust insulation

Insulated with 25mm foil

faces glasswool pipe

insulation, as supplied by

Glen Dimplex Australia.

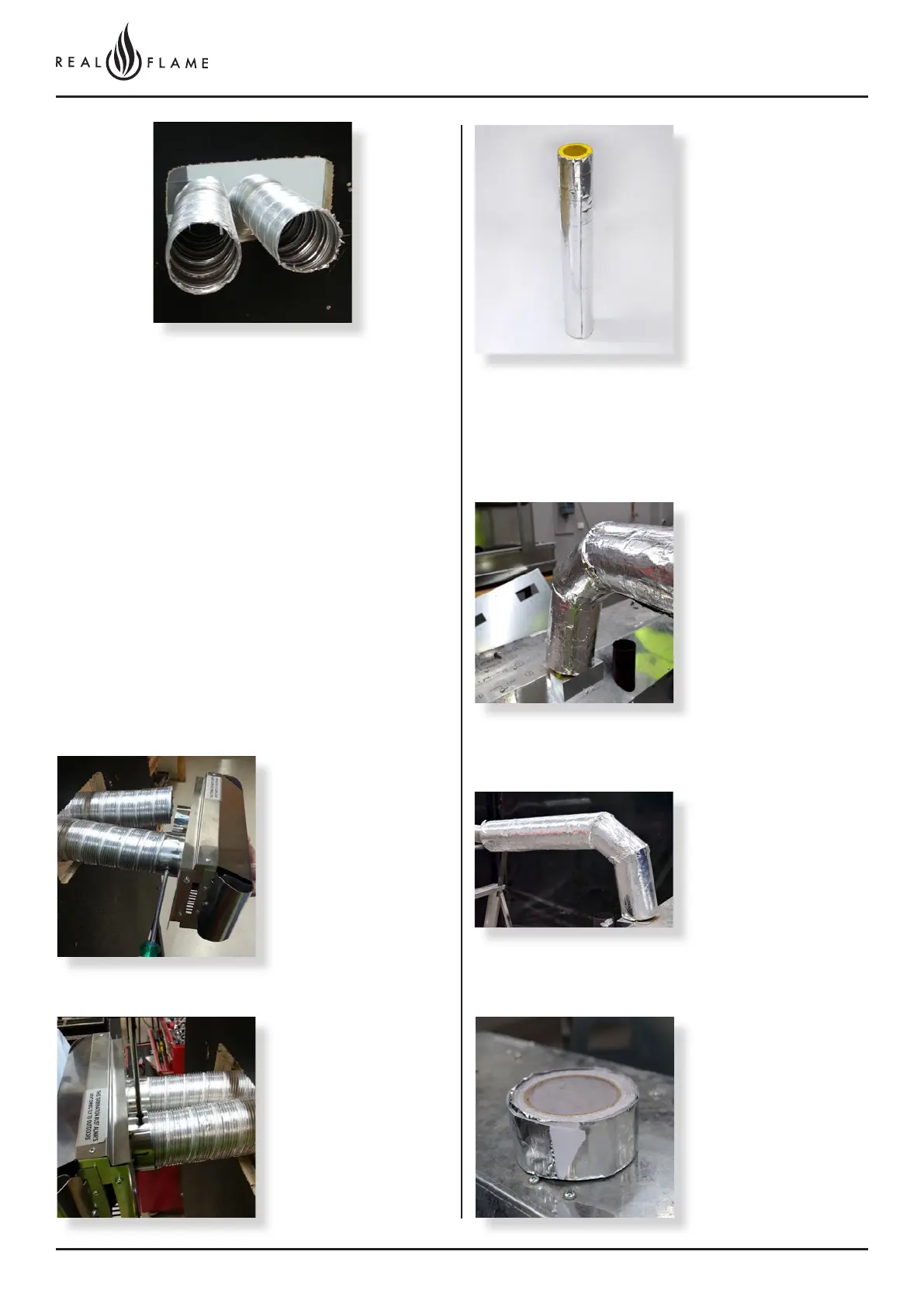

Bends were practical

should be insulated, by

cutting the insulation into

segments and taping

together.

Joins can be taped

together using aluminum

foil self adhesive tape.

Loading...

Loading...