77

Page

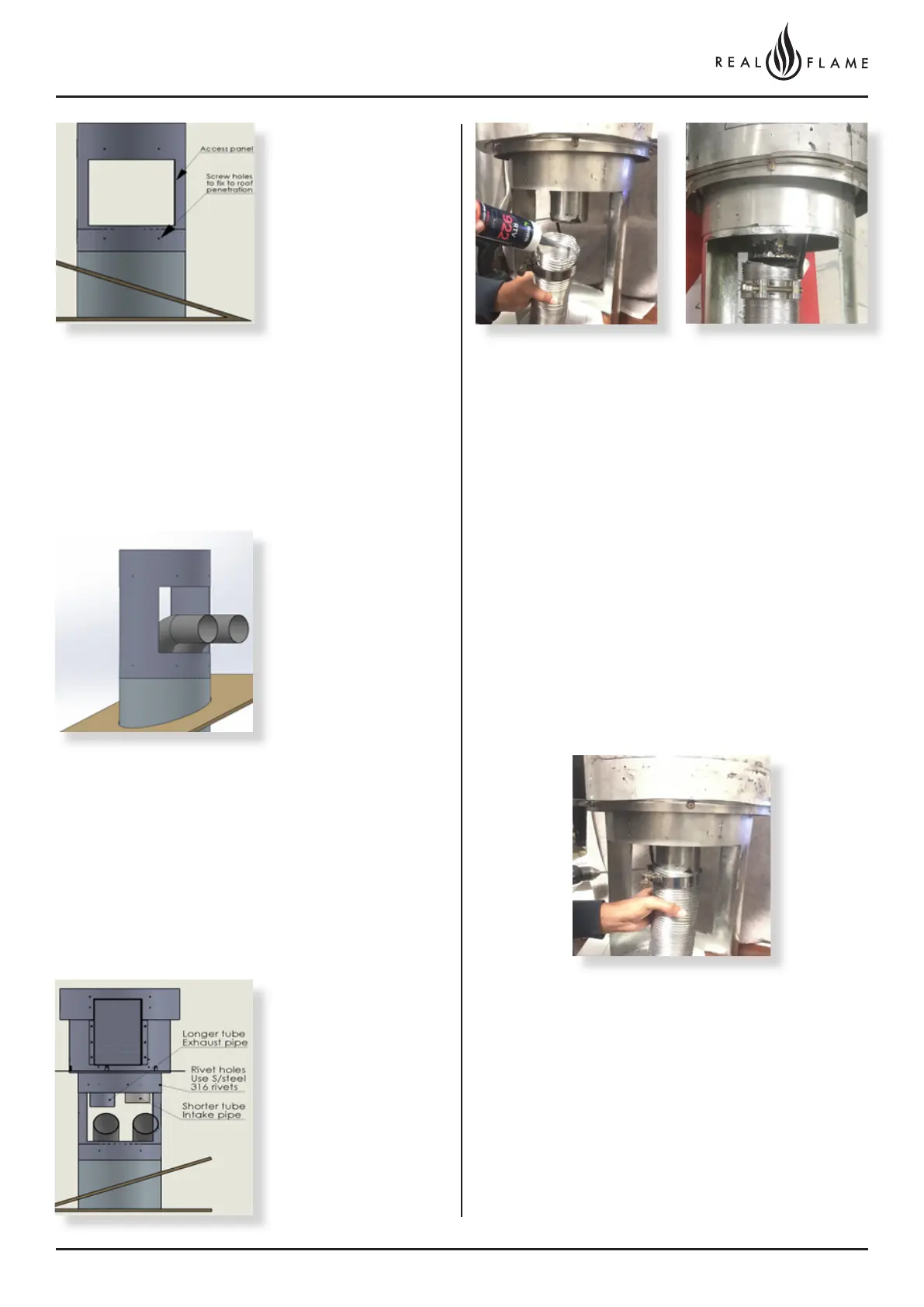

Fit the access panel to the

roof penetration.

Use the screw holes fix the

access panel to the roof

penetration.

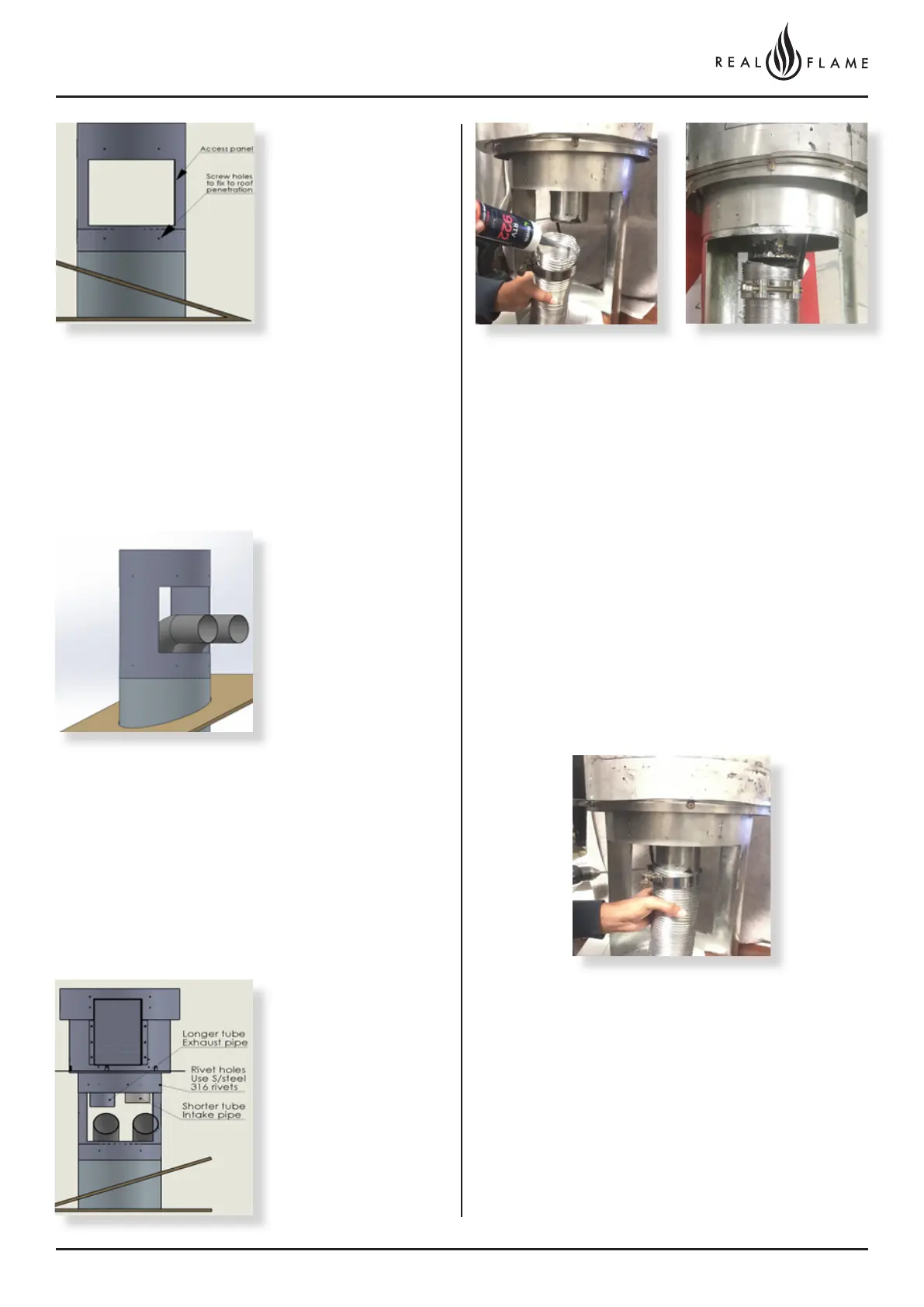

Run flue pipes through the

access cut outs before

fitting the termination on

for ease of installation.

(The picture is a reference

only. Take care not to flex/

bend the pipe too sharply

and risk slitting the pipe)

If possible to insulate

the flue pipe through the

roof penetration, then fit

insulation to the exhaust

pipe.

Fit the termination on to the

access panel and match

the rivet holes to rivet the

termination to the access

panel.

Use only the rivets

provided.

Slide flue onto connection spigot fully. Tighten clamp fully.

Wipe excess silicon, visually check connection to ensure

connection is fully sealed.

Ensure that the pipes are connected correctly and are not

inverted.

Use the labels to identify exhaust and intake spigots

On the termination end - Fit clamp loosely & apply

silicon inside the pipes. Apply an 8mm silicon bead fully

around the inside of the flue and on the flue spigot. Smear

smoothly around the surfaces.

Recommended Silicon – Non-acetic, neutral cure 200°C

or higher temperature rated. Bostik RTV 922 or similar.

Loading...

Loading...