99

Page

Poly Pro to Poly Pro flue connection

Verify gasket is sitting correctly.

Apply a light soapy water film to the gasket and tube end.

Insert pipe fully into end fitting, Pipe will push in smoothly

and evenly, should this not occur remove pipe and reset

gasket. Reapply light soapy film to ensure easy fit.

Rotate clip so catch is opposite the location tab

Clip catch into place to prevent flue pipes from separating.

Ensure pipes are clipped adequately.

Ensure a minimum of 3deg fall occurs towards the drain

end.

Installation

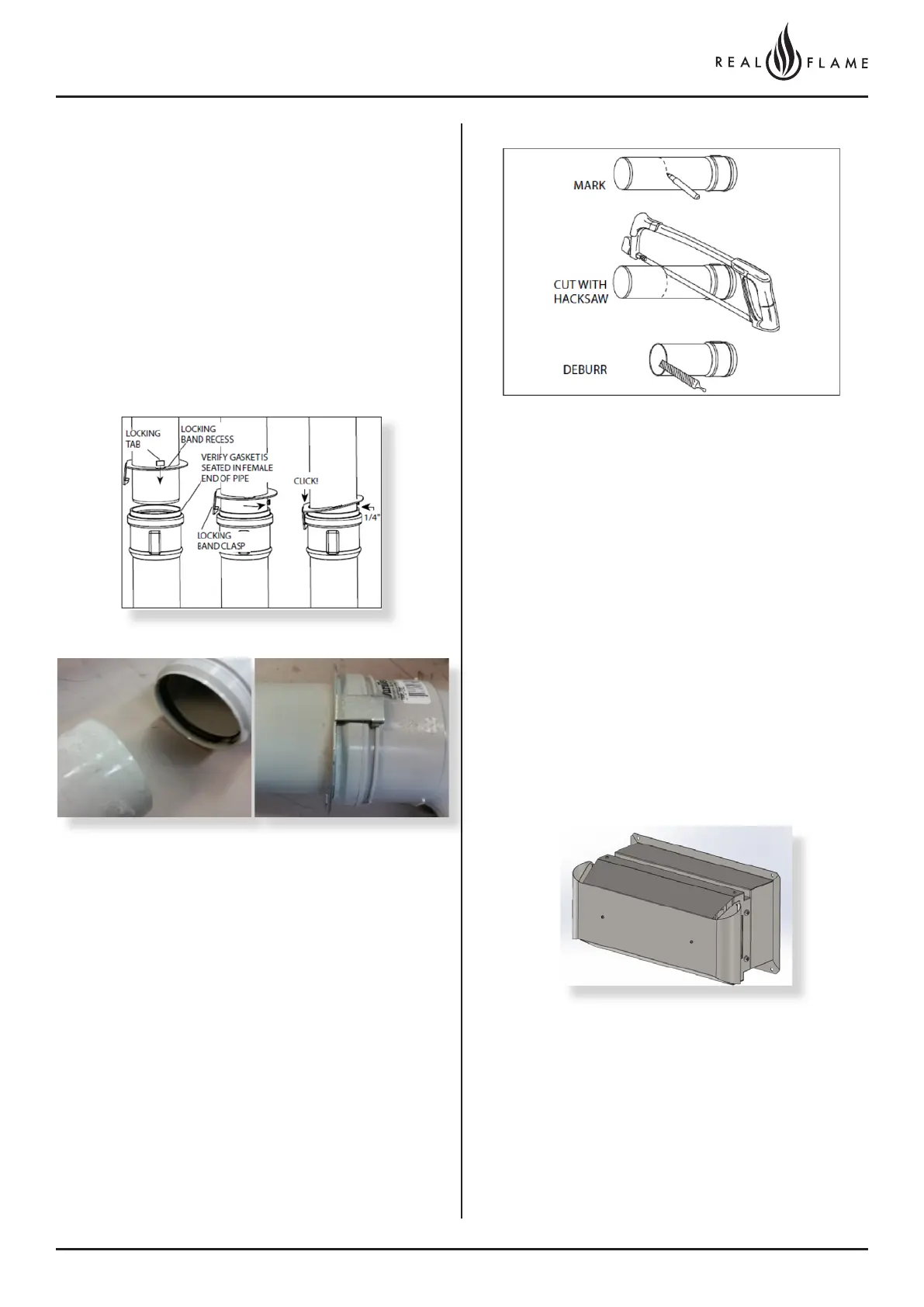

1. Pipe lengths may be cut to length. Use an alternative

clamp (PPS-PAC/PPS-LBC) for the connection if a locking

tab is removed.

• Cut square (not an angle) to the end of the pipe.

• Remove burrs before assembly.

2. Check with appliance manufacturer for any restrictions

or limits on vent length, number of elbows, etc.

3. The slope of the vent pipe must be at least

3° (50mm per meter) back to the appliance.

4. Every horizontal section must be supported.

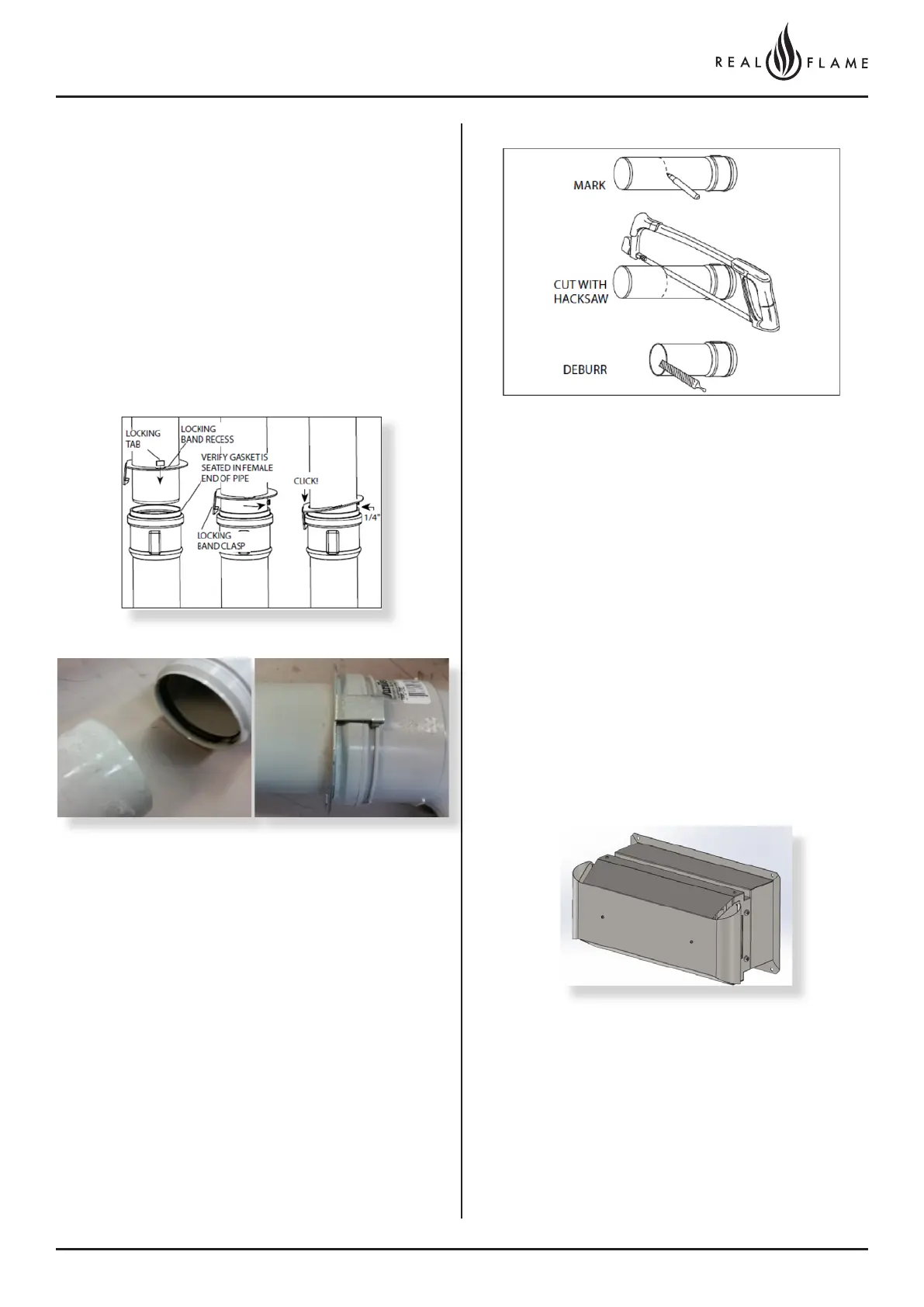

Poly Pro to Wall mounted terminal

Ensure terminal is affixed to the wall.

Verify gasket is sitting correctly in condensate drain

connection.

Apply a light soapy water film to the gasket and the tube

end.

Insert pipe fully into end fitting, Pipe will push in smoothly

and evenly, should this not occur remove pipe and reset

gasket. Reapply light soapy film to ensure easy fit.

Tighten hose clamp to restrain flue in place.

Locate terminal on wall and pre-drill mounting holes

where required.

Mark out the required penetration area. Cutout the area

in wall for the flue pipes and condensate drain.

(NOTE - Access to rear of terminal may be required to

assemble flue) Where access is not available a single

large cutout is required for the flues and the condensate

drain.

Loading...

Loading...