CAUTION

ESCAPING GASES OR FLUIDS HAZARD

Process Seal Materials Single Seal Certification (T-XX and T-200 Transducers)

• Wetted material for T-XX style transducers are 316SS or Inconel holders with

Hastelloy-C pins, Stycast 2850 Epoxy, and glass.

• Wetted materials for T-200 Style transducers are Titanium housing and NBR (Nitrile)

or FKM (Viton) O-ring material.

Only Daniel specified o-ring replacements shall be used for process seal o-ring materials

for T-200 transducers. No substitutions are allowed to maintain process seal integrity.

Verify chemical compatibility of material with components of process fluid.

Reference Parker Seals – Chemical Compatibility Catalog EPS 5350

• https://www.parker.com/literature/Engineered%20Polymer%20Systems/

5350_Appendixh.pdf

Failure to select the suitable meter seals may cause escaping gases or liquids, resulting

in injury or equipment damage.

WARNING

CRUSHING HAZARD

During meter installation or removal, always place the unit on a stable platform or

surface that supports its assembled weight.

Failure to comply could allow the meter to roll, resulting in serious injury or equipment

damage.

For basic maintenance, refer to Field hydrostatic pressure testing procedures.

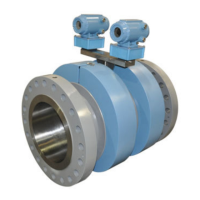

3.2 T-Slot transducer removal and installation

The T-Slot transducer assembly offers improved transducer alignment and superior

acoustic isolation between the transducer and the meter housing. The net result is

improved performance and stability. The assembly is used on Daniel 3417, 3416 and 3415

meters and is line pressure vented. The gas temperature ranges are as shown in Table 3-1.

Table 3-1: Temperature ranges for transducers, mounts and holders

Transducer type Temperature range Mount and holder type

T-21

1

-20 °C to +100°C (-4 °F to 212

°F)

Standard mounts/Holders/NBR

O-ring

Inconel Mounts/316L Holders,

NBR O-ring

Inconel Mounts/Inconel

Holders/FKM O-ring

Inconel Mounts/316L

Holders/FKM O-rings

Meter repairs Maintenance and Troubleshooting manual

August 2021 P/N 3-9000-791

44 Models 3415, 3416 and 3417 GUSM

Loading...

Loading...