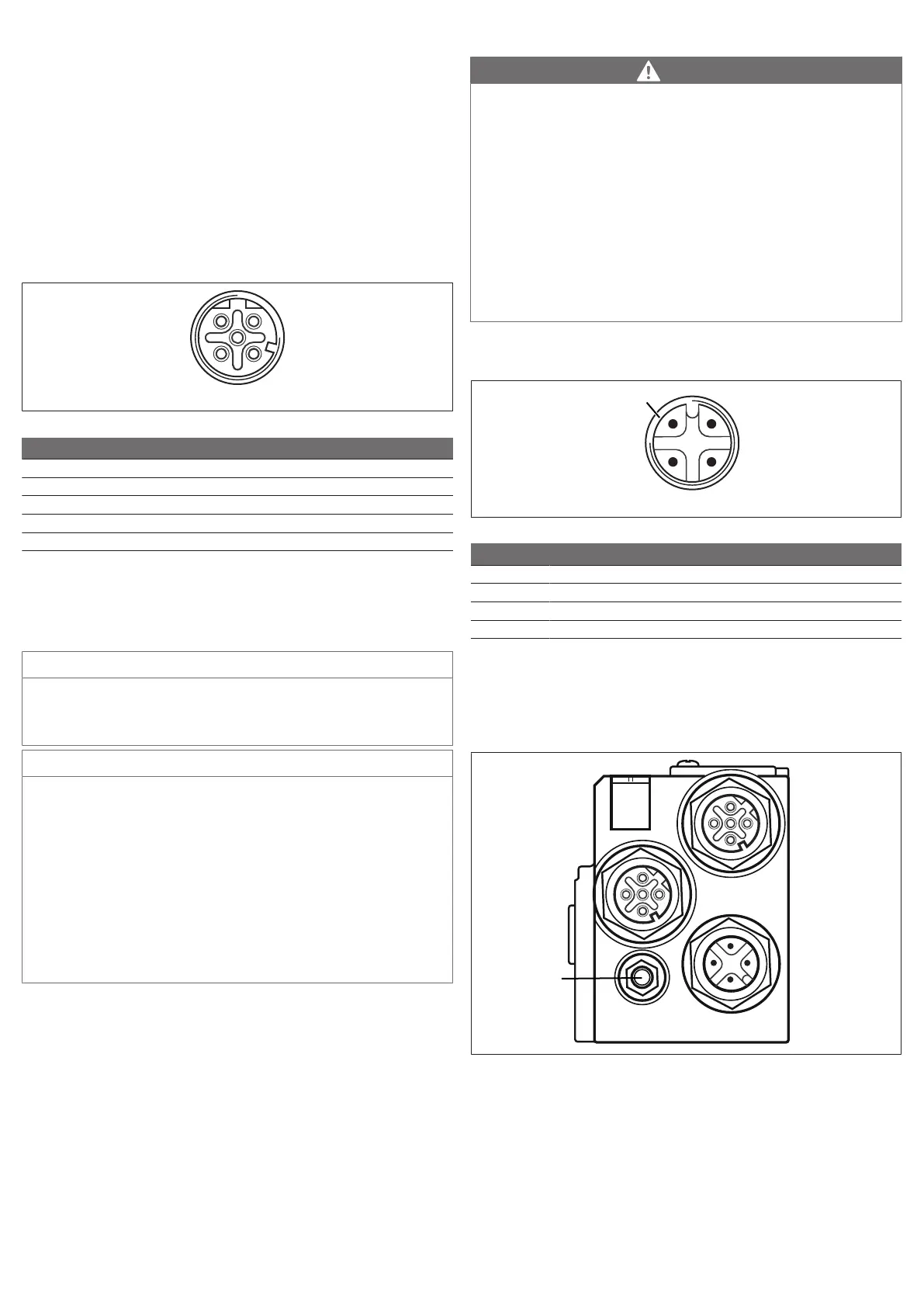

• X7E1 socket (5): fieldbus connection

• X7E2 socket (6): fieldbus connection

• X1S plug (7):

• 24VDC power supply for bus coupler

• Ground screw (8): functional earth

The tightening torque for the connection plugs and sockets is 1.5Nm +0.5.

The tightening torque for the M4x0.7 nut (SW7) on the ground screw is 1.25Nm

+0.25.

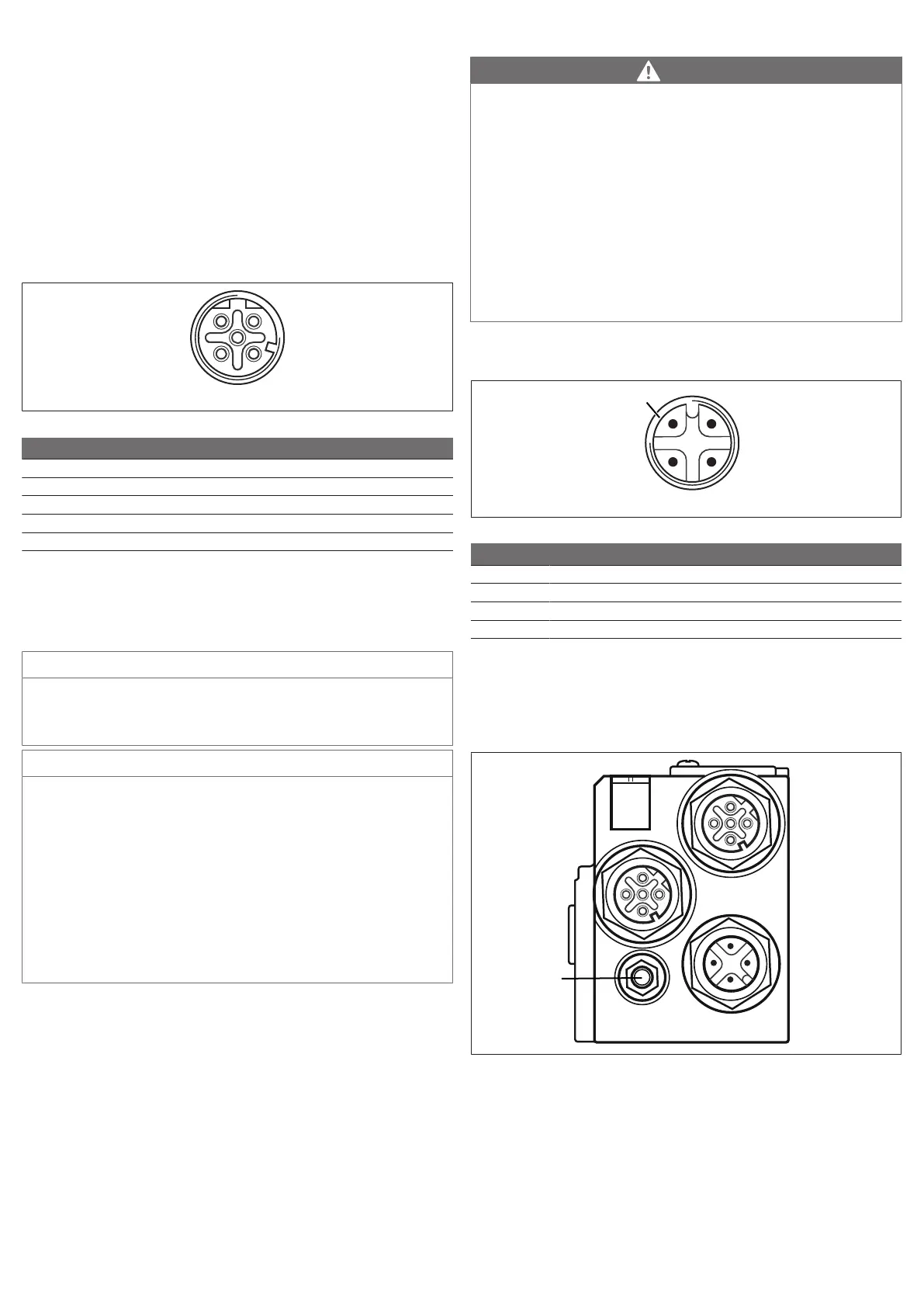

Fieldbus connection

The X7E1 (5) and X7E2 (6) fieldbus connections are designed as integrated M12

sockets, female, 4-pin, D-coded.

u See Table6 for the pin assignments for the fieldbus connections. The view

shown displays the device connections.

Table4: Pin assignments of the fieldbus connections

Pin X7E1 (5) and X7E2 (6) sockets

Pin 1 TD+

Pin 2 RD+

Pin 3 TD–

Pin 4 RD–

Housing Ground

The AESseries bus coupler for EtherNet/IP has a 100Mbit full duplex 2-port

switch, so that several EtherNet/IPdevices can be connected in series. As a result,

the controller can be connected to either fieldbus connection X7E1 or X7E2. Both

fieldbus connections are identical.

Fieldbus cable

NOTICE

Danger caused by incorrectly assembled or damaged cables!

The bus coupler may be damaged.

u Only use shielded and tested cables.

NOTICE

Faulty wiring!

Faulty wiring can lead to malfunctions as well as damage to the network.

1. Comply with the EtherNet//IP specifications.

2. Only a cable that meets the fieldbus specifications as well as the connection

speed and length requirements should be used.

3. In order to assure both the protection class and the required strain relief,

the cable and plug assembly must be done professionally and in accor-

dance with the assembly instructions.

4. Never connect the two fieldbus connections X7E1 and X7E2 to the same

switch/hub.

5. Make sure that you do not create a ring topology without a ring master.

Power supply

DANGER

Electric shock due to incorrect power pack!

Danger of injury!

1. Only use the following power supply for the bus coupler:

- 24VDC SELV or PELV circuits, each with a DC fuse that can interrupt a cur-

rent of 6.67A within max. 120s, or

- 24VDC circuits meeting the requirements for energy-limited circuits as

described in section9.4 of UL standard UL61010-1, third edition, or

- 24VDC circuits meeting the requirements for power-limited power

sources in accordance with section2.5 of UL standard UL60950-1, second

edition, or

- 24VDC circuits meeting the requirements of NEC ClassII in accordance

with UL standard UL1310.

2. Make sure that the power supply of the power pack is always less than

300VAC (outer conductor – neutral wire).

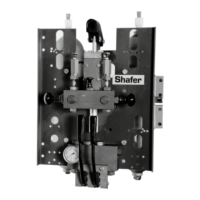

The X1S power supply connection (7) is an M12 plug, male, 4-pin, A-coded.

u See Table7 for the pin assignments for the power supply. The view shown dis-

plays the device connections.

Table5: Power supply pin assignments

Pin X1S plug

Pin 1 24VDC sensor/electronics power supply (UL)

Pin 2 24VDC actuator voltage (UA)

Pin 3 0VDC sensor/electronics power supply (UL)

Pin 4 0VDC actuator voltage (UA)

• The voltage tolerance for the electronic components is 24VDC ±25%.

• The voltage tolerance for the actuator voltage is 24VDC ±10%.

• The maximum current for both power supplies is 4A.

• The power supplies are equipped with internal electrical isolation.

Functional earth connection

u To discharge the EMC interferences, connect the FE connection (8) on the bus

coupler via a low-impedance line to ground.

The cable cross section must be designed according to the application.

4.1.2 LED

The bus coupler has 6LEDs.

The table below describes the functions of the LEDs. For a comprehensive de-

scription of the LEDs, see section g11.LED Diagnosis on the Bus Coupler.

AVENTICS™ EtherNet/IP | R412018139-BAL-001-AG | English 30

Loading...

Loading...