7

August 2017

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

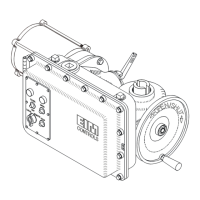

Assembly to Valves

3. Lower actuator over Stem onto valve ange. The screws thru valve ange into

actuator must engage a minimum of one full screw diameter deep into bottom

base and be tightened to a preload. See assembly drawing for screw size and

torque to tighten properly.

4.

3.2 Mounting Screws

If EIM supplied adaptation, the mounting screws are included. If adaptation to valve was

the responsibility of others, the mounting screws are not furnished by EIM. Screws thru

adapter MUST engage a minimum of one screw diameter deep into EIM actuator base.

1. Screw Stem Nut on Stem until it enters Drive Sleeve. Line (52) Key and (54) Drive

Sleeve keyway and insert (52) Key.

2. Turn handwheel in Open direction, pulling Stem Nut into Drive Sleeve until it

bottoms out (valve will begin to open).

CAUTION:

Locknut must be tight against stem nut.

3. Lower Locknut (55) over Valve Stem and screw into place rmly against top of

Stem Nut. Tap Locknut ears using brass drift until tight.

3.2.1 Thrust Spool (Model 4000 & 5000)

1. Locate Thrust Mounting bolts.

2. Remove eight mounting bolts and separate Spool from actuator.

3. Position Spool over Valve Stem. Thread Spool onto Valve Stem until it meets valve

plate.

4. Bolt and secure Spool onto valve.

5. Position actuator above Spool. Lower actuator onto Spool while manually rotating

the unit until ears on Stem Nut and ears on main Drive Sleeve mesh.

6. Grease ange face before securing unit to Spool.

7. Re-install thrust plate mounting bolts. Tighten to proper torque.

NOTE:

Reverse procedure if Stem Nut needs to be replaced. Actuator does not need to be

returned to factory for this procedure.

Section 3: Assembly to Valves

Loading...

Loading...