Chapter 3 Installation and Wiring 31

EV2000 Series Universal Variable Speed Drive User Manual

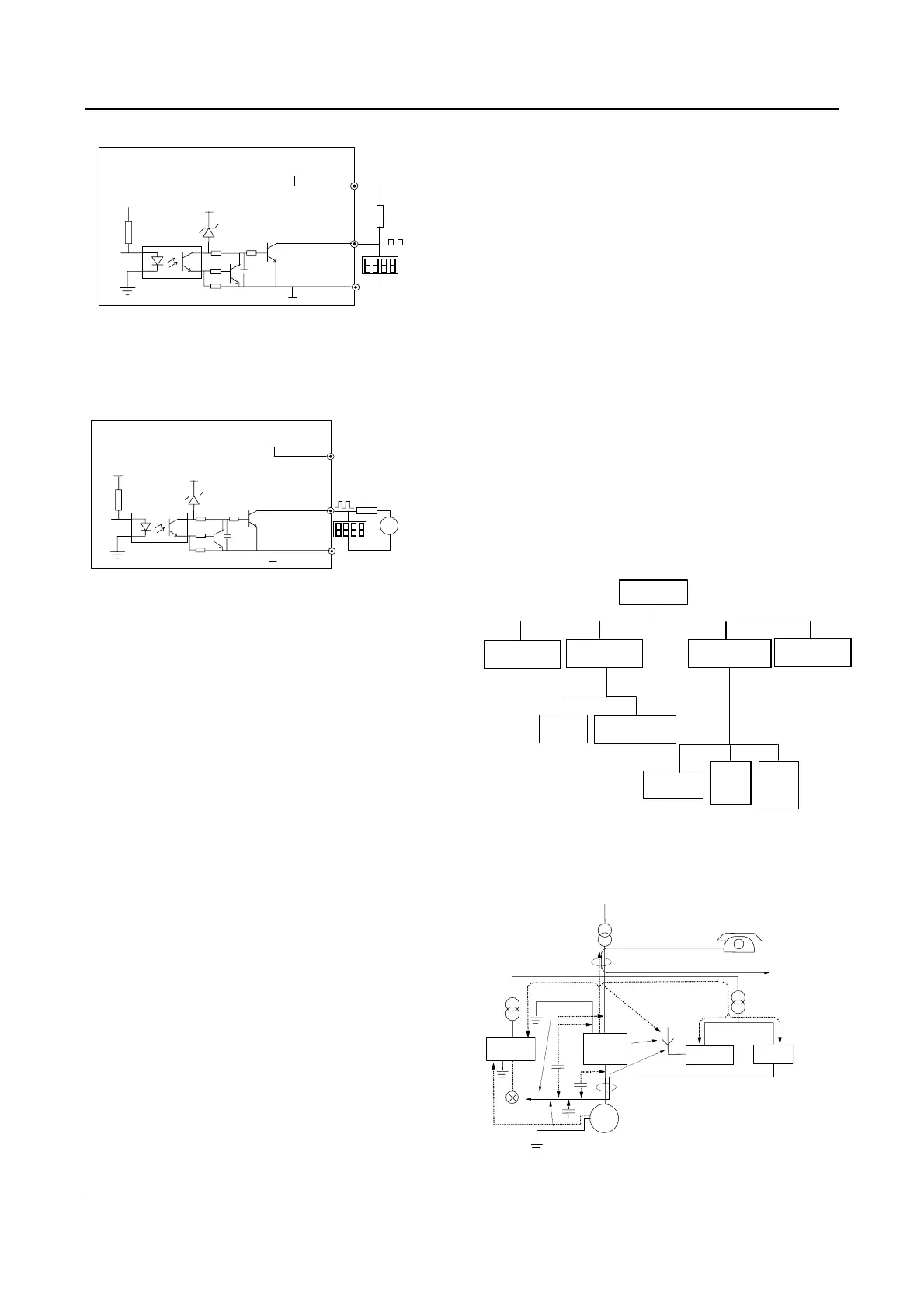

+24V

EV2000

P24

4.7K

DO

COM

+5V

+24V

Digital

frequency

meter

Fig. 3-30 Wiring 1 of output terminal DO

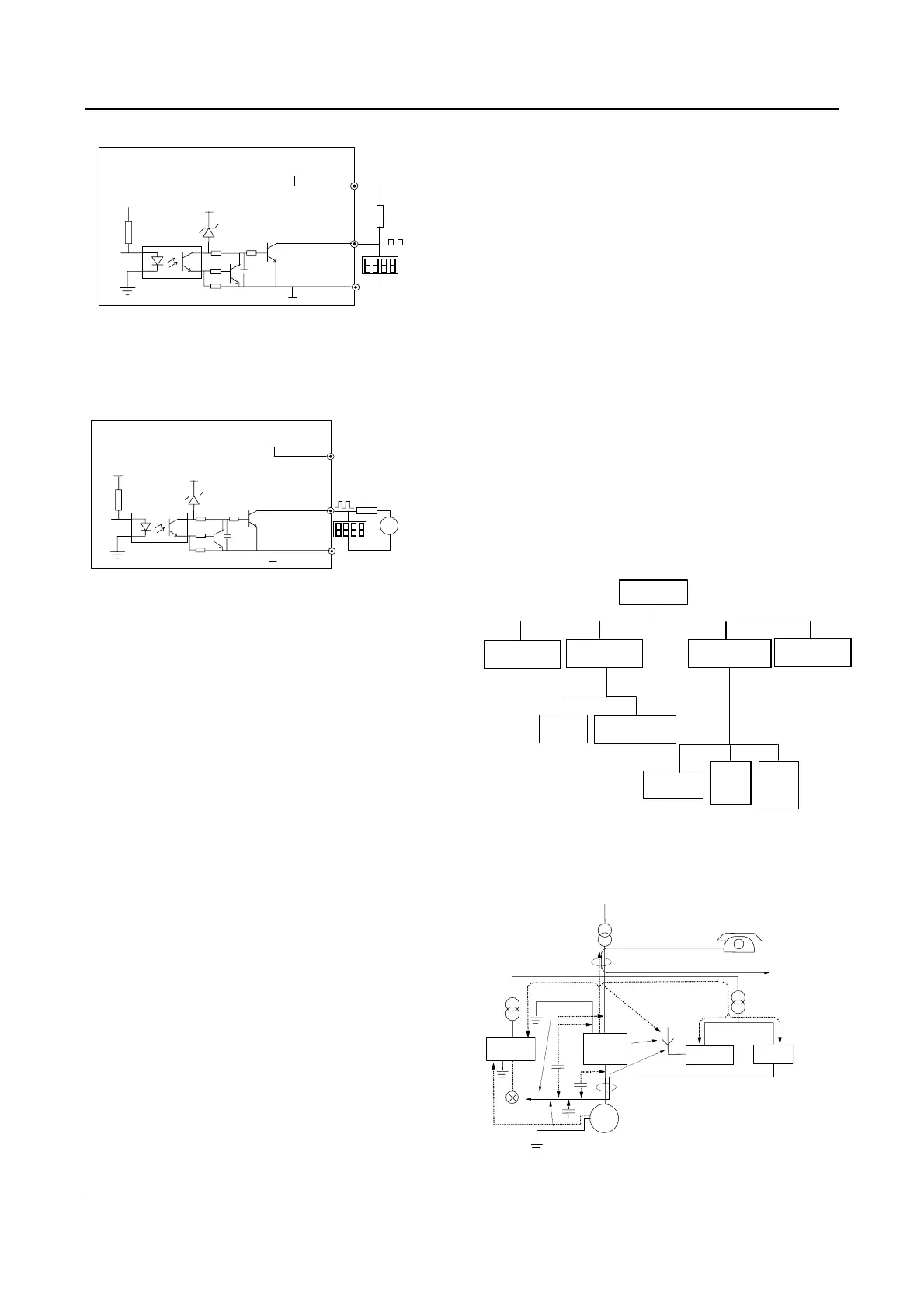

④Pulse output terminal DO can also use the external

9~30V power supply and the wiring is shown in Fig.3-31.

+24V

EV2000

P24

4.7K

DO

COM

+5V

+24V

Digital frequency

meter

~

9 30V

+

-

Fig. 3-31 Wiring 2 of output terminal DO

3) Wiring relay output terminals TA, TB and TC.

If the drive drives an inductive load (such as relay or

contactor), then a surge suppressing circuit should be

added, such as RC snub circuit (pay attention that the

leakage current must be smaller than the holding current

of the controlled relay or contactor) and varistor or a

free-wheeling diode (used in the DC electric-magnetic

circuit and pay attention to the polarity during

installation). Snubbing components should be as close

to the coils of relay or contactor as possible.

Notes:

1. Don’t short circuit terminals P24 and COM, otherwise

the control board may be damaged.

2. Please use multi-core shielded cable or multi-stranded

cable(above 1mm) to connect the control terminals.

3. When using a shielded cable, the shielded layer’s end

that is nearer to the drive should be connected to PE.

4. The control cables should be as far away(at least 20cm)

from the main circuits and high voltage cables as possible

(including power supply cables, motor cables, relay cables

and cables of contactor). The cables should be vertical to

each other to reduce the disturbance to minimum.

5. The resistors R in Fig. 3-27 and Fig.3-28 should be

removed for 24V input relays, and the resistance of R

should be selected according the parameters of relay for

non-24V relay.

3.4 Installation Methods Compliant With

EMC Requirements

The drive inevitably generates noise due to its high

switching frequency, so relevant EMC problems must be

solved so as to reduce the drive’s disturbance to

external equipment. This chapter deals with the

installation methods compliant with EMC requirements

from the aspects of noise suppression, field wiring,

grounding, leakage current and the using of power filter.

This chapter can be used as a reference for field

installation.

3.4.1 Noise Suppressing

The noise generated by the drive may disturb the

equipment nearby. The degree of disturbance is

dependent on the drive system, immunity of the

equipment, wiring, installation clearance and earthing

methods.

1. Noise categories

Route⑥

...

Route⑤

...

Route④

...

ESD induction

Noise

Route

①

...

Electro-magnetic

induction noise

Route ,

⑦⑧

...

Transmission noise

of power cables

Earthing

noise

Conduction noise

Route③

...

Route②

...

Noise

Ttransmission noise

in space

Radiation noise

of motor

Radiation

noise

of power

cables

Radiation

noise

of power

cables

Fig. 3-32 Noise categories

2. Noise propagation paths

D

r

i

v

e

R

a

d

i

o

⑧

⑤

⑥

④

③

③

④

⑦

②

①

⑤

Sensor

Motor

Sensor's

power supply

Phone

M

e

t

e

r

Fig. 3-33 Noise transmission paths

Loading...

Loading...