56 Chapter 5 Parameter Introductions

EV2000 Series Universal Variable Speed Drive User Manual

In the above Fig., KP: proportional gain; Ki: integral gain

In Fig. 5-31, refer to F5.01~F5.15 for the definitions of

close-loop reference, feedback, error limit and

proportional and Integral parameters.

There are two features of internal PI of EV2000:

The relationship between reference and feedback can

be defined by F5.08~F5.11.

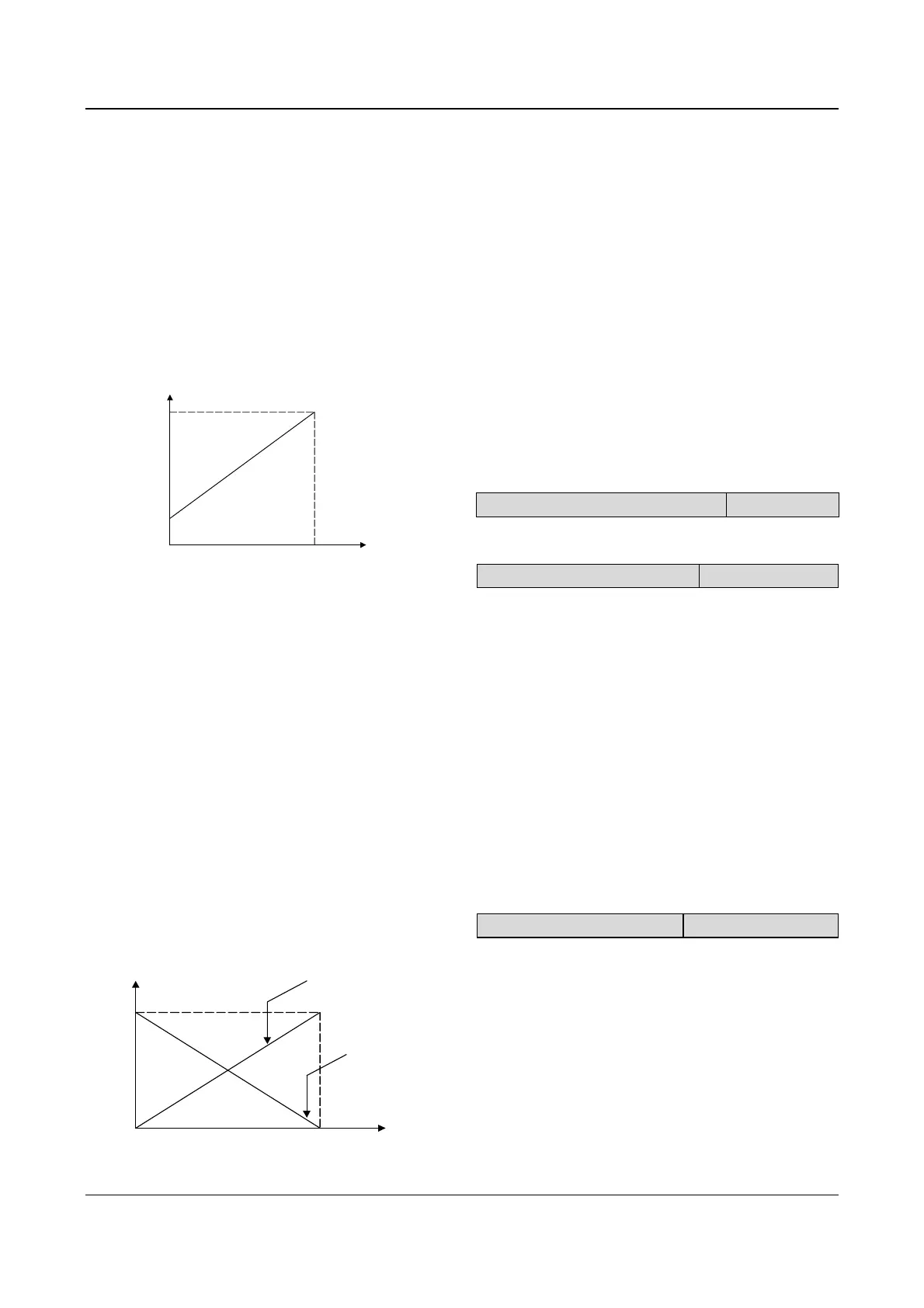

For example: In Fig. 5-29, if the reference is analog

signal of 0~10V, the controlled value is 0~1MP, and the

signal of water-level sensor is 4~20mA, then the

relationship between reference and feedback is shown

in Fig. 5-32.

10V

0

Reference

4mA

20mA

Feedback

Fig. 5-32 Reference and feedback

The reference value is a 0~10V signal (10V corresponds

to 100%); and the feedback value is 4Ma~20mA (20mA

corresponds to 100%).

In Fig 5-31, “reference regulation” and “feedback

regulation” mean that the reference value and feedback

value are converted from current or voltage value to

percentage values, so that feedback value can be added

to or subtracted from the reference value.

Close-loop reference is selected via F5.16 to satisfy

different application requirements.

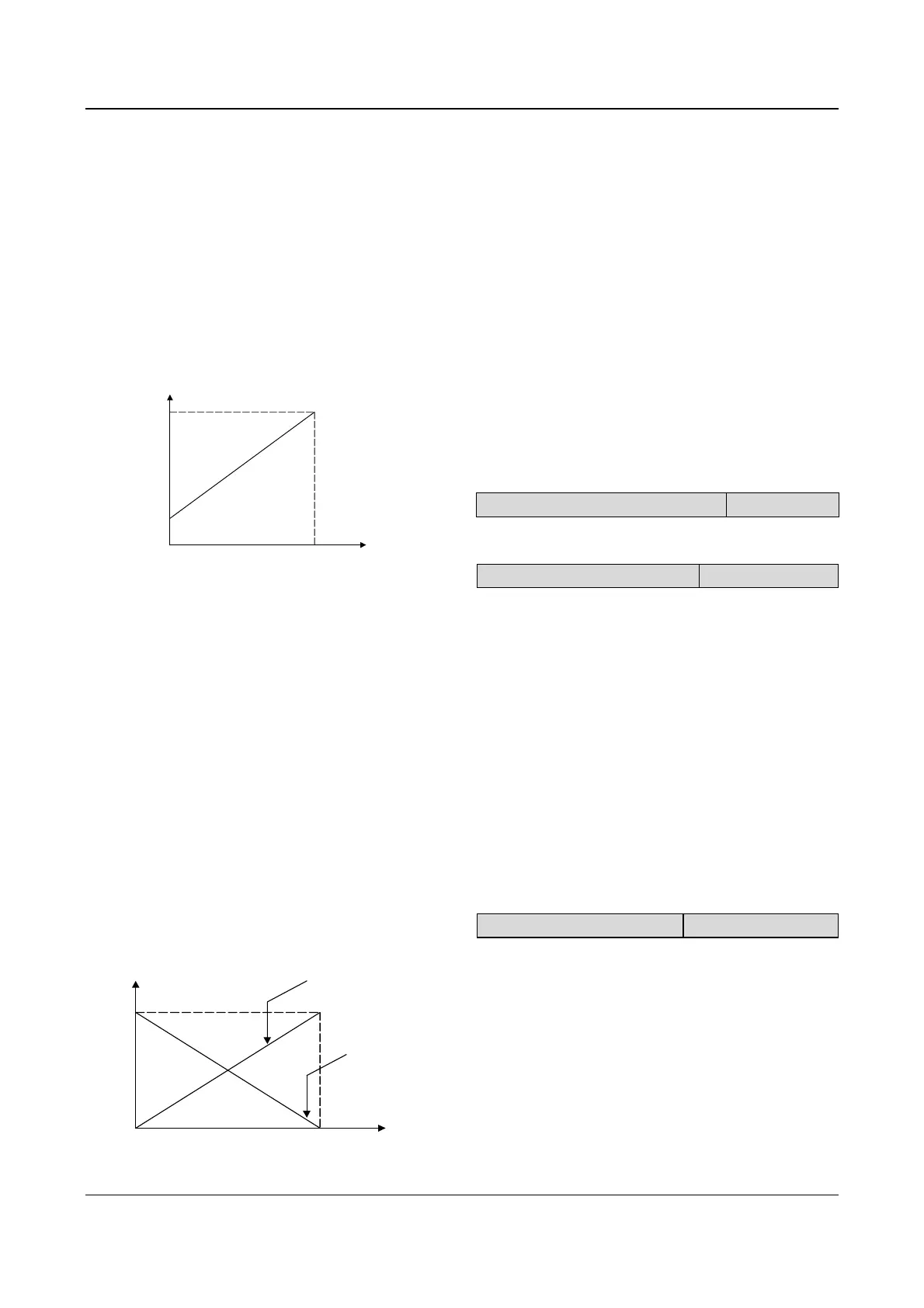

If the motor’s speed is required to increases with the

reference speed, this kind of control characteristic is

called positive characteristic. If the motor speed is

required to decrease when the reference value

increases, this control characteristic is called negative

characteristic.

Please refer to Fig. 5-33 and F5.16.

Close loop

reference

Speed

Positive

Negative

Fig. 5-33 Close-loop control characteristic

After the control type is determined, follow the

procedures below to set close loop parameters.

Determine the close-loop reference and feedback

channel (F5.01 and F5.02);

The relationship between close-loop reference and

feedback value (F5.08~F5.11) should be defined for

close-loop control;

For speed close-loop, the close-loop speed reference

and the number of revolutions of PG (F5.06~F5.07)

need to be determined;

Determine the close-loop regulation characteristic, i.e.

whether the motor speed increase with the reference.

Please see F5.16.

Set up the integral regulation function and close-loop

frequency presetting function (F5.17~F5.19);

Adjust the close-loop filtering time, sampling cycle, error

limit and gain(F5.12~F5.15).

F5.00 Close-loop control function

Range:0. 1【0】

0: disabled

1: enabled

F5.01 Reference selector

Range:0. 1. 2【1】

0: digital input

Take the value of F5.05 (when the setting is analog

close-loop, F5.02

=0~5);

Take the value of F5.06 (when the setting is pulse

close-loop, F5.02

=6).

1: VCI analog voltage input(0~10V)

2: CCI analog input

Analog input range:0~10V(Jumper CN10 is placed at

side V), or 0~20mA(Jumper CN10 is placed at side I).

Note:

Use pulse feedback to control the speed. If the reference is

analog signal, then 0~10V (4~20mA) reference corresponds

to synchronous speed n

0

(n

0

=120fmax/P).

F5.02 Feedback selector

Range:0~6【1】

0: VCI 0~10V analog voltage input

1: CCI analog input

2: VCI + CCI

3: VCI-CCI

4: Min {VCI,CCI}

5: Max {VCI,CCI}

Settings of jumper CCI are the same with the above.

When current input is selected, the signal will be

converted into voltage signal by the formula:

Voltage value = current value (mA)/2;

Loading...

Loading...