Chapter 7 Application Guidance 39

EV3200 Door Control Inverter User Manual

Table 7-1 Motor parameters setting table

Parameter Name Setting Remark

F0.01 Control mode 0

F0.02 Control command selection 0

F0.04 Max. output frequency 50Hz

F4.00 PG type 0

F4.01 Pulse number per revolution 200

F4.02 PG direction 0

F6.00 Motor type selection 0

F6.01 Motor rated power *

F6.02 Motor rated voltage *

F6.03 Motor rated current *

F6.05 Motor rated frequency *

F6.06 Motor rated spinning speed *

F6.07 Motor tuning 0

Parameters in this table are factory settings, adjust the OD

parameters according to the actual OD operating conditions

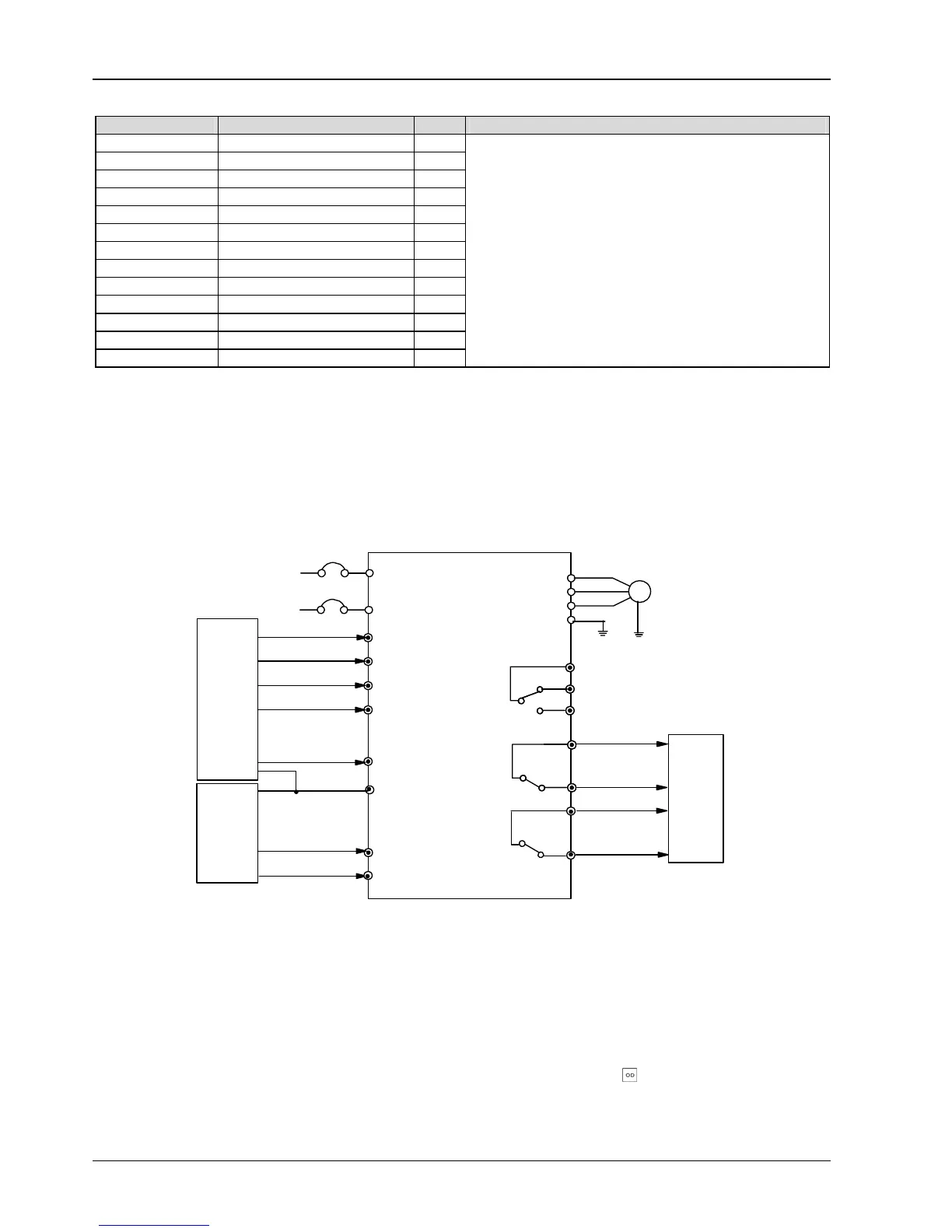

7.2 Speed Control

7.2.1 System Wiring Diagram

In speed control, speed decrease contacts are used to decrease the speed, and the position limiting signal is used to judge

whether the door is opened or closed completely. System wiring diagram for speed control 1 is shown in Figure 7-2.

L

N

Single phase

power supply

50/60Hz

M

X1

CD

U

V

W

PE

MCCB

Fault relay

OD

OD command input

CD command input

Complete OD

relay output

OD speed

decrease NO input

OD position

limiting NO input

light curtain or safety

edge signal NO input

COM

EV3200 inverter

PB3

PC3

PA3

PC2

PA1

PC1

PA2

X2

X3

X4

X5

CD speed

CD position

limiting NO input

Elevator door mechanical system

Control system

Complete CD

relay output

Control system

decrease NO input

Figure 7-2 System wiring diagram for speed control

7.2.2 Testing Procedures

1. Wiring according to Figure 7-2.

2. Switch on the inverter, set F9.18 to 2, load defaults. Refer to

4.1 Operation for parameter setting.

3. Carry out motor tuning according to instructions provided in 7.1 Motor Type Setup.

4. Set F0.02 to 1 (keypad control mode), set the parameters according to Table 7-2, press

to start the operation. If

bumping or unsmooth operation occurs in the process, adjust the CD or OD curve according to the OD curve for speed control

shown in Figure 6-4 and CD curve for speed control shown in Figure 6-8.

Loading...

Loading...