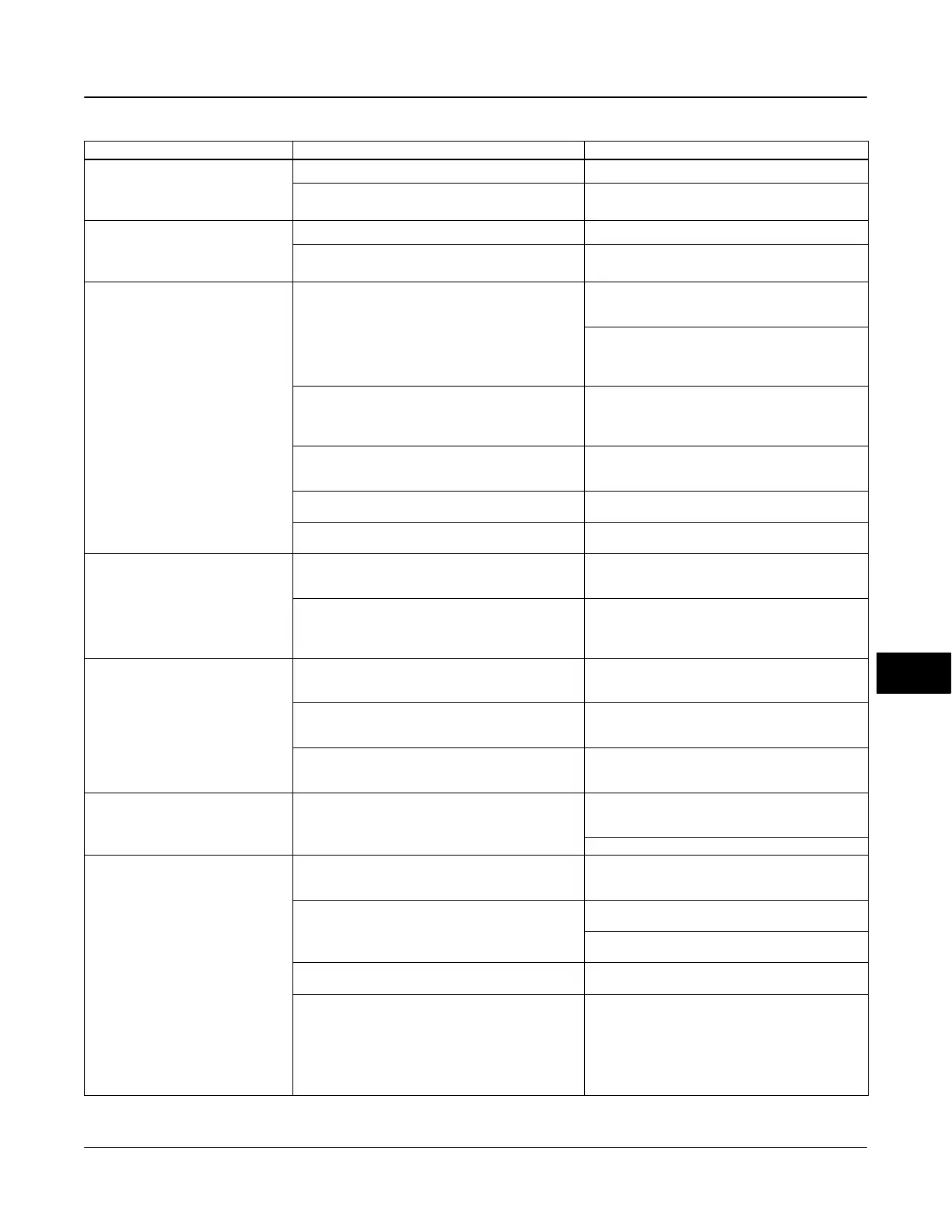

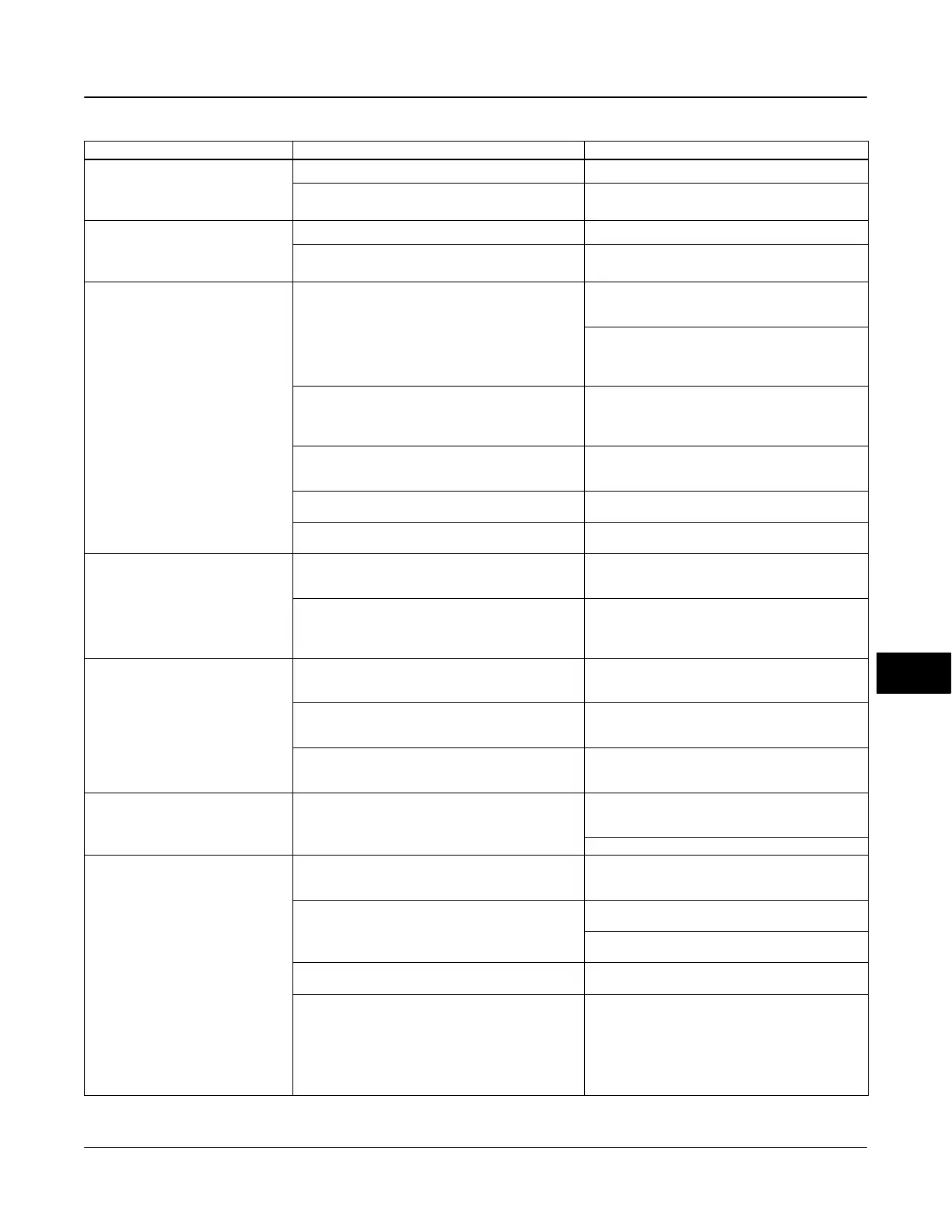

Maintenance

March 2006

10-17

Table 10-2. Instrument Troubleshooting (Continued)

Symptom ActionPossible Cause

7. Transducer block Setpoint

(FINAL_VALUE [13]) is not being

automatically updated from the AO

block.

7.a Transducer block mode in not Auto. 7.a Change transducer block mode to Auto.

7.b AO block is not active. 7.b Change resource block parameter

FEATURE_SEL to de-selected DO Control.

8. Transducer block setpoint

Setpoint(D) (SETPOINT_D [32]) is not

being automatically updated from the

DO block.

8.a Transducer block mode is not Auto. 8.a Change transducer block mode to Auto.

8.b DO block is not active. 8.b Change resource block parameter

FEATURE_SEL to selected DO Control.

9. Valve does not move when the set

point is changed

9.a A function block actual mode is Out of Service or

Transducer Block Actual mode is Out of Service or

Manual.

9.a1 Change the target mode to an operational mode

(see F

OUNDATION fieldbus Communication,

Appendix A and host system documentation).

9.a2 Verify that the correct block (AO or DO) is

configured in Feature Select in the resource block.

Only the selected out block is able to set the

transducer setpoint and move the valve.

9.b Pneumatic connections are incorrect or supply

pressure is incorrect

9.b Check pneumatic connections and supply

pressure. Be sure supply pressure regulator is set

correctly (see Pressure Connections on page 2-16 of

the Installation Section).

9.c Instrument is in fault state. 9.c Set Clear FState to Clear (Refer to Fault State on

page 5-5 of the Detailed Setup / Blocks Section, or

host system documentation).

9.d The valve has failed. 9.d Apply a pneumatic pressure to the valve actuator

and check valve action.

9.e The I/P converter or relay has failed. 9.e Replace the I/P converter or relay (see Replacing

the I/P Converter on page 10-6).

10. Valve does not stroke from 0 to

100% with set point change

10.a Insufficient supply pressure or leak in pneumatic

connections.

10.a Check supply pressure and supply pressure

regulator setting. Check for leaks around pneumatic

connections.

10.b Setpoint may be limited. 10.b Check the AO Block values of SP_HI_LIMIT

and SP_LO_LIMIT (see page 5-74 of the Detailed

Setup / Blocks Section or host system

documentation).

11. Deviation between set point and

actual valve position remains.

11.a Digital valve controller output is in cutoff. 11.a Check values for Travel Cutoff High and Travel

Cutoff Low (see page 5-28 of the Detailed Setup /

Blocks Section or host system documentation).

11.b Digital valve controller is not calibrated correctly 11.b Perform Auto or Manual Travel Calibration (see

page 4-6 of the Basic Setup and Tuning Section or

Travel Calibration on page 6-2.)

11.c Incorrect turning. Tuning that is too conservative

will result in excess error.

11.c Perform Stabilizing/Optimize Valve Response

procedure to adjust tuning and stabilize/optimize

valve response (see Stabilize/Optimize on page 4-7).

12. The valve cycles, does not stay on

set point.

12.a Large amount of packing friction.

12.a1 Perform Stabilizing/Optimize Valve Response

procedure to adjust tuning and stabilize/optimize

valve response (see Stabilize/Optimize on page 4-7).

12.a2 Use a larger size actuator.

13. Valve responds too slowly.

13.a Insufficient instrument gain. 13.a Perform Stabilize/Optimize Valve Response

procedure to adjust tuning and stabilize valve

response (see Stabilize/Optimize on page 4-7).

13.b I/P converter input filter clogged or air blockage in

I/P ass’y nozzle block.

13.b1 Replace I/P converter filter (see Replacing the

I/P Filter on page 10-6).

13.b2 Replace I/P converter (see Replacing the I/P

Converter on page 10-6).

13.c O-ring(s) between I/P converter missing or hard

and flattened losing seal.

13.c Replace O-ring(s) (refer to the I/P Converter

section on page 10-6).

13.d I/P ass’y out of spec. 13.d I/P ass’y nozzle may have been adjusted.

Verify drive signal (55% to 80%) (refer to Elect and

Config on page 5-30 of Detailed Setup / Blocks or

host system documentation).

Replace I/P ass’y if drive signal is continuously high

or low (see Replacing the I/P Converter on page

10-6).

−Continued−

10

Loading...

Loading...