• Entrained gas will go up

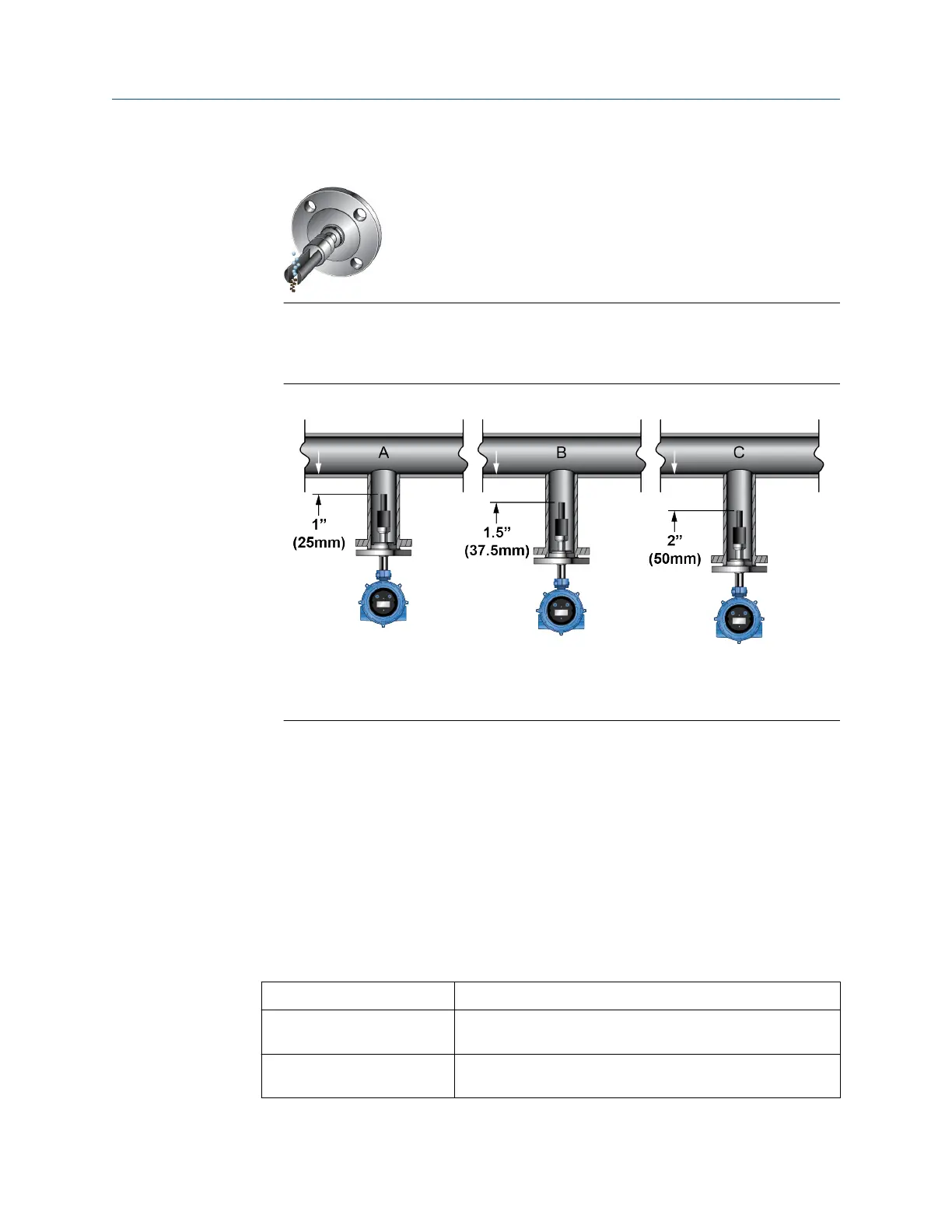

2. Size the T-piece so that the meter tines are retracted 1 in (25 mm) from the main

pipe wall. For higher flow rates, increase this by 0.4 in (10 mm) for every 1 m/s

increase in the main flow rate.

Figure 3-7: Pipe wall installation

A. Velocity ≤ 10 ft/sec (3 m/s)

B. 10 < velocity ≤ 13 ft/sec (4 m/s)

C. 13 < velocity ≤ 16 ft/sec (5 m/s)

3.2.2

Mount with a 3 in (76 mm) T-piece (flanged fitting)

Mount the FDM in a T-piece pipeline for slurry measurement applications. The T-piece

should be 3 in (76 mm) (DN80) and mounted at an angle to ensure that it will self-drain.

Flow velocity as low as 1.0m/s is acceptable, and preferred velocity is 3m/sec. Care should

be taken at flow velocities of 5m/sec, as there is an increased risk of the T-piece clogging.

Additional cleaning may be required.

Prerequisites

• 3 in (76 mm) T-piece (flanged) installations are recommended for processes with the

following conditions:

Flow

0.5 to 5 m/s (at the pipe wall)

Viscosity Up to 100 cP, or 1000 cP if the insertion distance does not

exceed 1 in (25 mm).

Temperature -58 °F (-50.0 °C) to 392 °F (200 °C)

-40 °F (-40.0 °C) to 392 °F (200 °C) in hazardous areas

Installation Manual Mounting

MMI-20020989 May 2019

Installation Manual 23

Loading...

Loading...