Note

— Flow velocity at the pipe wall and fluid viscosity must be within the limits shown to

ensure that the fluid within the pocket is refreshed in a timely manner. This

installation will not respond as rapidly as the free-stream installation to step

changes in viscosity.

— The thermal mass of the flanges may affect the response time of the meter to

temperature changes.

• Attach the PFA ring and circlip to the underside of the meter flange before installing

the meter in your application (see Attach the PFA ring and circlip).

Note

If you are using a Zirconium meter, this meter uses a self-locking PFA ring and does not

require a circlip.

Procedure

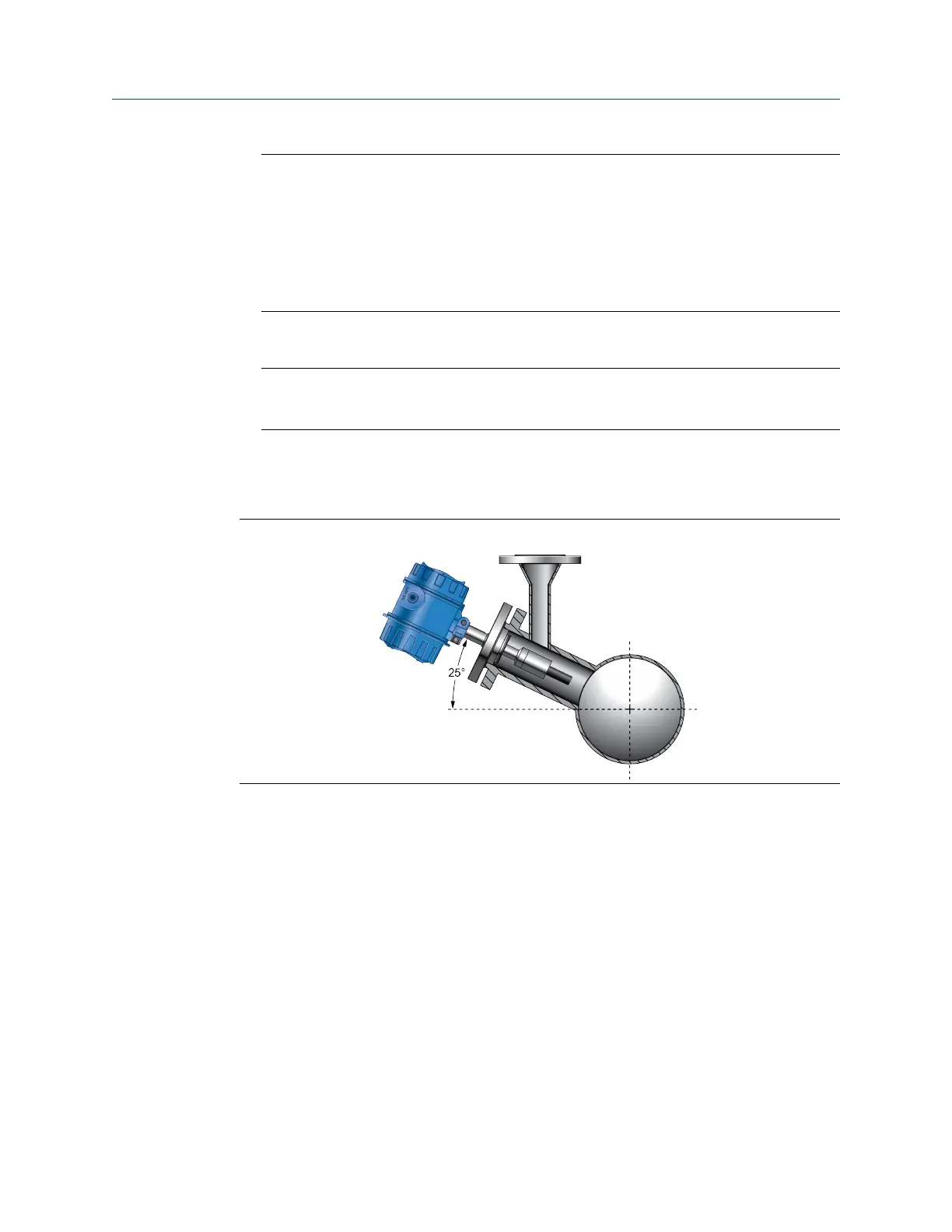

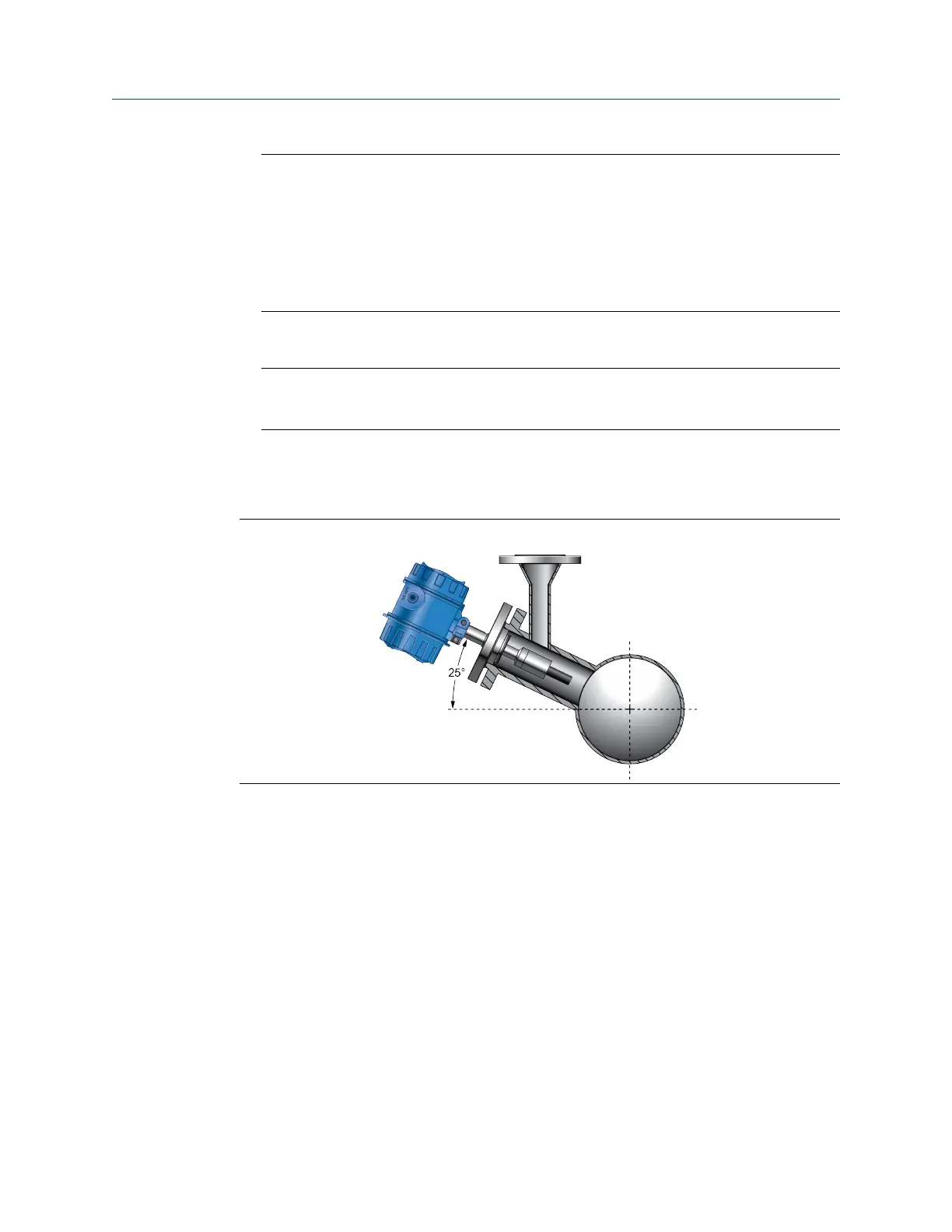

See Figure 3-8 or Figure 3-9 for information on installing the meter with a flanged fitting in

a 3 in (76 mm) T-piece.

Figure 3-8: 3 in (76 mm) T-piece installation: horizontal pipe

Insert a purge/drain connection on the upper part of the T-piece. You can use the purge

connection to flush the pipe if necessary.

Mounting Installation Manual

May 2019 MMI-20020989

24 Micro Motion Fork Density Meter

Loading...

Loading...