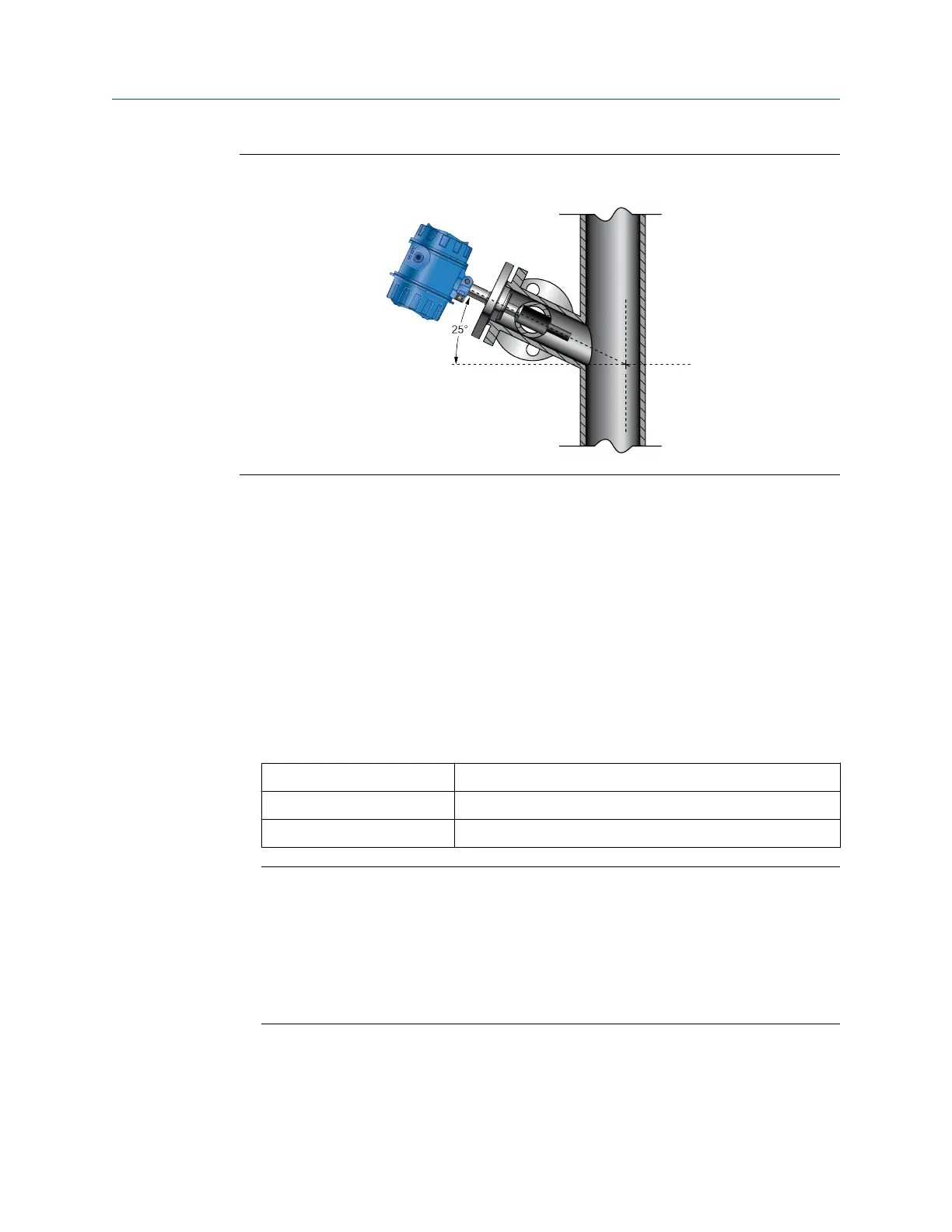

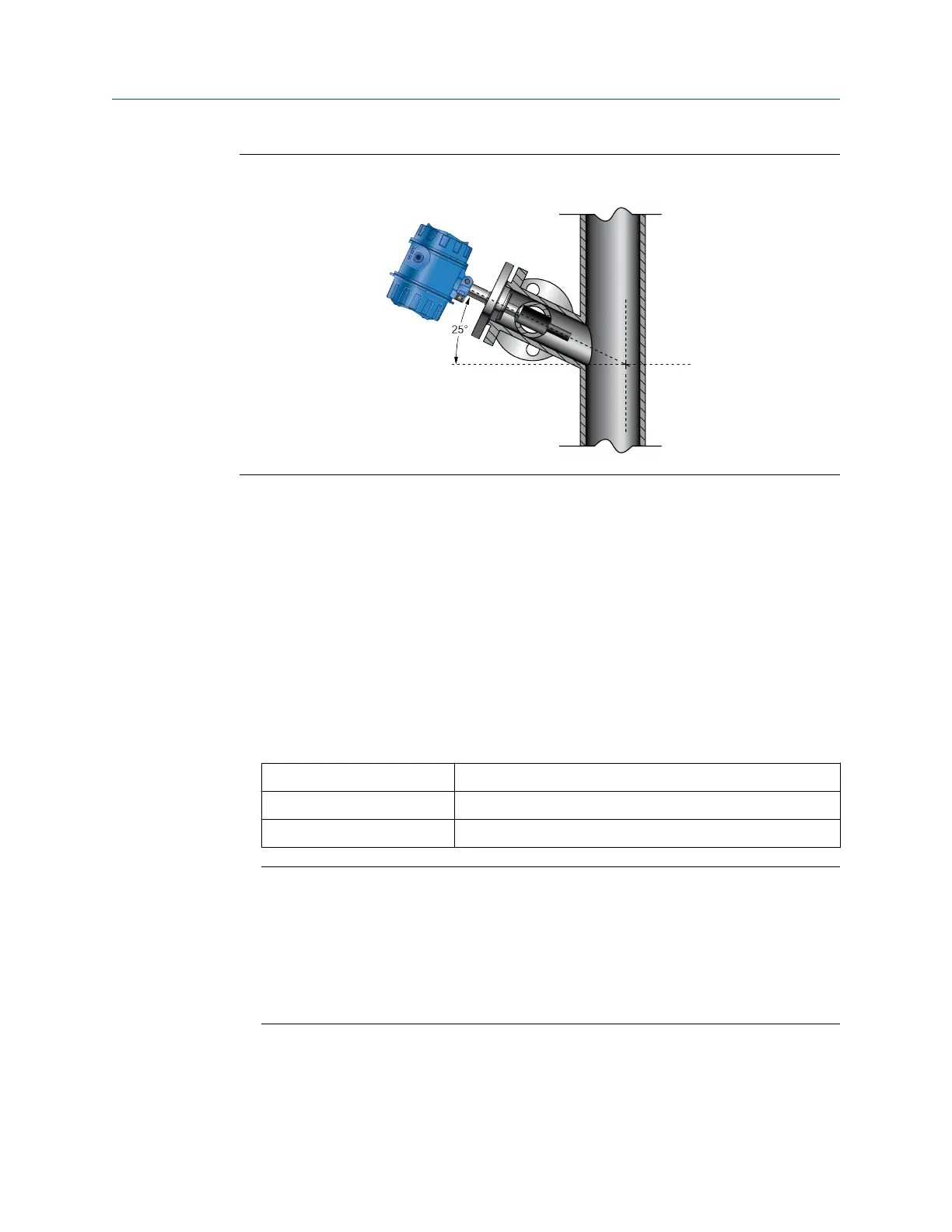

Figure 3-9: 3 in (76 mm) T-piece installation: vertical pipe

Insert a purge/drain connection on the side of the T-piece. You can use the purge

connection to flush the pipe if necessary.

3.2.3

Mount with a T-piece (weldolet fitting)

The weldolet for T-piece installations has a 1.5 in (38 mm) taper lock fitting and is supplied

to be welded on 4 in (102 mm), 6 in (152 mm), 8 in (203 mm) or 10 in (254 mm) pipelines.

A weldolet installation ensures that the tines of the meter are oriented correctly and are

fully inserted into the fluid stream.

Prerequisites

• T-piece (weldolet) installations are recommended for processes with the following

conditions:

Flow 0.5 to 3 m/s (at the pipe wall)

Viscosity Up to 100 cP, or 250 cP under some conditions

Temperature -58 °F (-50.0 °C) to 392 °F (200 °C)

Note

— Flow velocity at the pipe wall and fluid viscosity must be within the limits shown to

ensure that the fluid within the pocket is constantly refreshed. This installation will

not respond as rapidly as the free-stream installation to step changes in viscosity.

— If temperature variations are a critical factor in your process, the reduced thermal

mass of the taper-lock fitting of the weldolet renders it more able to track rapid

changes in temperature

• Before fitting the weldolet, you must bore a 2.1 in (53 mm) diameter opening in the

pipeline to accept the meter. You must weld the weldolet to the pipeline concentrically

with the pre-bored hole.

Installation Manual

Mounting

MMI-20020989 May 2019

Installation Manual 25

Loading...

Loading...