Safety

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

142 Mentor MP User Guide

www.controltechniques.com Issue: 3

the maximum speed must be limited by the drive.

3: Coiler/uncoiler mode

Positive final speed demand: a positive resultant torque will give torque

control with a positive speed limit defined by the final speed demand. A

negative resultant torque will give torque control with a negative speed

limit of -5rpm.

Negative final speed demand: a negative resultant torque will give

torque control with a negative speed limit defined by the final speed

demand. A positive resultant torque will give torque control with a

positive speed limit of +5rpm.

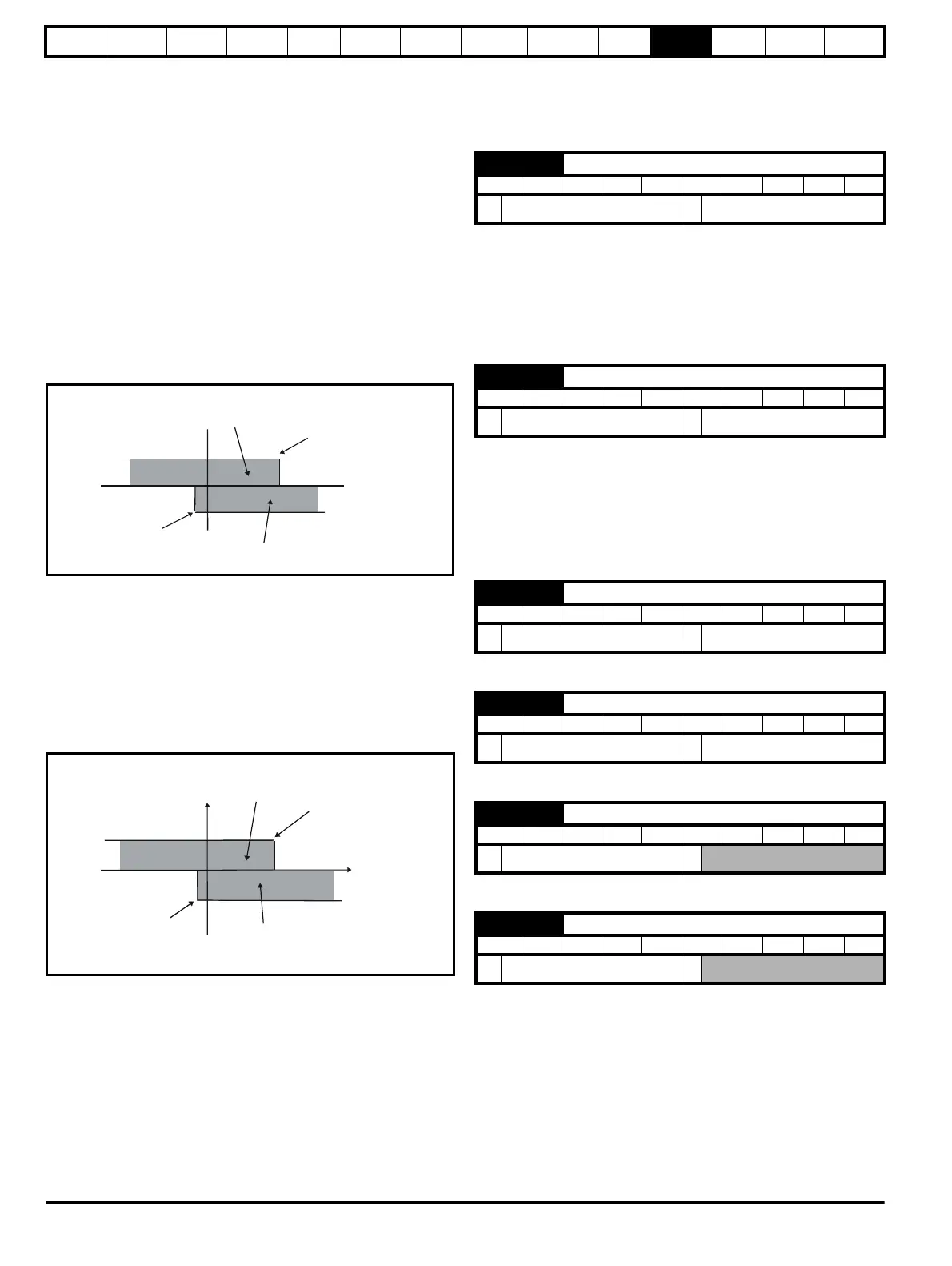

Example of coiler operation:

This is an example of a coiler operating in the positive direction. The final

speed demand is set to a positive value just above the coiler reference

speed. If the resultant torque demand is positive the coiler operates with

a limited speed, so that if the material breaks the speed does not exceed

a level just above the reference. It is also possible to decelerate the

coiler with a negative resultant torque demand. The coiler will decelerate

down to -5rpm until a stop is applied. The operating area is shown in the

following diagram:

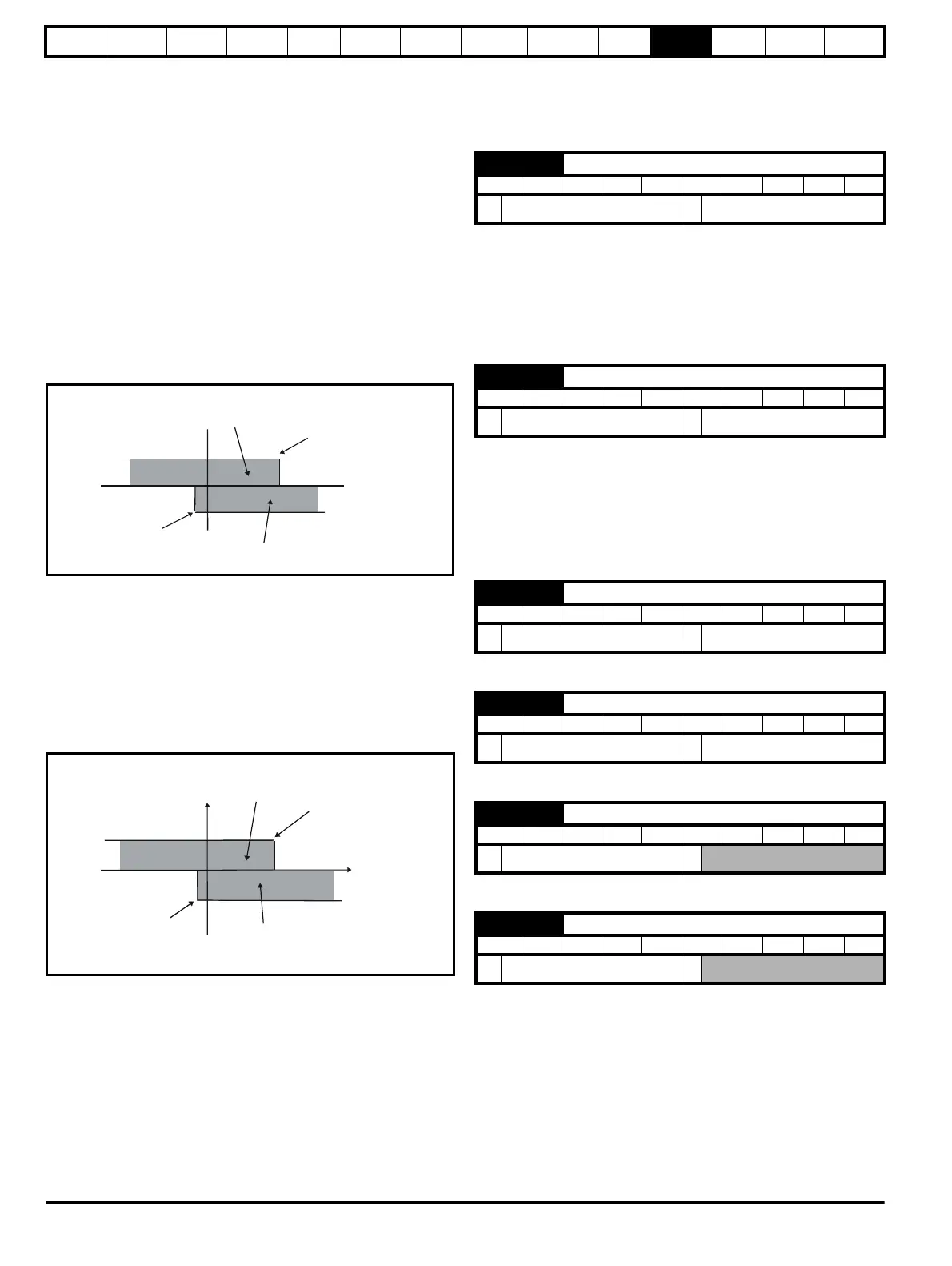

Example of uncoiler operation:

This is an example for an uncoiler operating in the positive direction. The

final speed demand should be set to a level just above the maximum

normal speed. When the resultant torque demand is negative the

uncoiler will apply tension and try and rotate at 5rpm in reverse, and so

take up any slack. The uncoiler can operate at any positive speed

applying tension. If it is necessary to accelerate the uncoiler a positive

resultant torque demand is used. The speed will be limited to the final

speed demand. The operating area is the same as that for the coiler and

is shown below:

:

4: Speed control with torque feed-forward

The drive operates under speed control, but a torque value may be

added to the output of the speed controller. This can be used to

improve the regulation of systems where the speed loop gains need

to be low for stability.

11.22.4 Current limit tapers

With some motors the commutation limit of the motor requires that the

maximum armature current be reduced at higher speeds, the current

limit tapers can be used to provide this speed dependent current limit.

Sets a threshold value of speed feedback, beyond which Pr 4.31

changes to 1 to indicate that the threshold has been exceeded, and is

the starting point for taper 2, if implemented. The current limit reduces,

as a function of speed, to an end point defined by Pr 4.29.

The output of the taper block controls Pr 4.18.

If only 1 taper is used, it must be taper 1. If both are used, taper 1 must

be first. Refer to Figure 11-20.

Sets a threshold value of speed feedback, beyond which Pr 4.32

changes to 1 to indicate that the threshold has been exceeded, and is

the starting point for taper 2, if implemented. The current limit reduces,

as a function of speed, to an end point defined by Pr 4.30.

The output of the taper block controls Pr 4.18.

If only one taper is used, it must be taper 1. If both are used, taper 1

must be first. Refer to Figure 11-20.

Defines the current at the end of taper 1.

Defines the current at the end of taper 2.

Indicates when speed feedback has exceeded threshold 1.

Indicates when speed feedback has exceeded threshold 2.

Final speed

demand

Area for coiler operation, speed

limited to ref and positve torque

Area for decelerating the coiler, reverse

speed limited and negative torque

-5rpm

Speed

Torque

-5rpm

Area for normal uncoiler

operation: negative torque,

limited to low speed in reverse

Speed reference

Area for accelerating

uncoiler: positive torque,

limited speed

Speed

Tor que

4.27 Current taper 1 threshold

RW Uni US

Ú

0.0 to 10,000.0 rpm

Ö

10,000 rpm

4.28 Current taper 2 threshold

RW Uni US

Ú

0.0 to 10,000.0 rpm

Ö

10,000 rpm

4.29 Current taper 1 end point

RW Uni US

Ú

0 to 1000.0 %

Ö

1000.0 %

4.30 Current taper 2 end point

RW Uni US

Ú

0 to 1000.0 %

Ö

1000.0 %

4.31 Taper threshold 1 exceeded

RO Bit

Ú

OFF (0) or On (1)

Ö

4.32 Taper threshold 2 exceeded

RO Bit

Ú

OFF (0) or On (1)

Ö

Loading...

Loading...